SULDGE PUMP

Uni boost Self Priming Centrifugal De watering Pumps are designed and manufactured for optimum efficiency to cater different needs of water handling. The pump construction is suitable for handling muddy & sewage water, contaminated water with solids up to 40mm. Features : > Efficient design and performance as available in international market > Automatic air releasing while priming is design specialty with added feature of quick and self-priming > Design of impeller is semi open / open vane type for non-clogging and unable to handle solids. > Back pull out design for repair possible without distributing pipelines > All rotating parts are dynamically balanced for smooth running and low vibration > Long product life due to replaceable wearing parts > Available in Monoblock Pump set and bare pump design > Bare pump can be coupled with either motor or engine > Motor designed for wide voltage fluctuations for monoblock pump sets * From 180 to 240 volts for single phase * From 350 to 450 volts for 3 phase > Easy maintenance due to availability and interchangeability of spares Specification : CAPACITY Head: 6 to 34 MetersDischarge: 76.8 to 1.0lit per second Pipe Size: 40 x 40 to 150 x 150 mm Power Rating For motor drive bare pump : 0.75 kW to 18.70 kW (1.00 HP to 25.00 HP)For engine drive bare pump: 4.00 kW to 19.50kW (6.00 HP to 26.00 HP)

...more

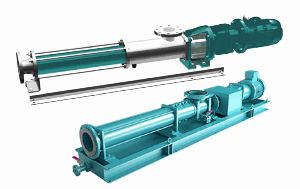

Screw Pump

Progressing Cavity Pumps are rotary positive displacement pumps. The main component, a metal rotor, which is in the shape of a single external helix, rotates around its on axis in the direction of rotation (say clockwise); while the axis of the rotor, revolves in the opposite direction (say anticlockwise) around the axis of the stator. The stator is made of and elastomeric bonded to end alloy steel tube. The stator itself is in the shape of an internal double helix. The rotor is contained within the stator and forms a continuous seal along the length of the stator. The above movement produces cavities at reduced pressures which move axially from the inlet to the outlet conveying the fluid at fixed flow rate proportional to the rotational speed. Features : > Abrasion resistant chrome plated rotor > Stator elastomers to suit specific requirement > Wide range of material of construction > Hardened bush pin type universal joint sealed and grease lubricated > Heat treated, hard chrome plated drive shaft Specification : UBH Series: Standard S SeriesCapacity: upto 250 m3/hr Head 12 kg/cm2Capacity: upto 72 m3/hr Head 24 kg/cm2UBH AG Series: Sugar Type S SeriesCapacity: upto 250 m3/hr Head 12 kg/cm2Capacity: upto 72 m3/hr Head 24 kg/cm2UBH VT Series: Vertical Type S SeriesCapacity: upto 72 m3/hr Head 24 kg/cm2

...more

multistage selfpriming pump

UniBoost multistage selfpriming pumps use the side channel design principle. The pumps are built as single stage or multistage pumps. All the wetted parts are made from SS 316 investment casting using lost wax process giving excellent surface finish, sound casting, giving minimum resistance to flow resulting in better efficiencies. The pump stages are staggered redially to bring about balance and minimize shaft deflection. The open star (vane) type impeller are individually hydraulically balanced thus eliminating the axial thrust on the external ball bearings of the pumps. The pumps are fitted with M-seal. Features : > The pumps are built as single stage or Multistage > All wetted parts are SS-316 investment casting > Selfpriming - side channel design principle > The pump stages are staggered redially to bring about balance and minimize shaft deflection > The pumps are fitted with M-seal.

...more

Motorise Barrel Pump

UniBoost Electrical Operated Barrel Pump is useful for safe and efficient handling of high corrosive chemical solvents, acid, plating solution etc. DRIVE MOTOR : Electric cord , continuous duty rated, 1 Phase. Note: Note : Flow Rate & Head mentioned are based on Water as testing fluid at ambient conditions. Flow rate & Head varies as viscosity changes. Features : • Maximum flow rate 100 ltr / minute. • Max discharge pressure up to 12 mtr. • Light Weight • Easy Maintenance • Self priming

...more

Monoblock Pump

UniBoost Centrifugal Monoblock Pumps - UCM Series are designed and manufactured for optimum efficiency to cater to different needs of water handling. The pump range is suitable for a wide range of applications in Commercial and Industrial areas Features : > Monoblock Construction > Wide range to suit a variety of requirements > High effeciency, Less Power Consumption > Pumps with Stainless Steel Sleeve for less Shaft water > Trouble free operations with low maintenance Specification : Standard Specification> Range: 1.5kW to 22kW (2.0 HP to 30.0 HP)> Supply: 415V +/- 10%, 50Hz, 3phase> Pipe size: 50 x 40 mm to 100 x 100 mm.> Liquid Temperature: Suitable upto 90 degree celsius water> Total Head: upto 90 metres> Capacity: 3000 LPM> Liquid: Clear water> Rotation: Clockwise as viewed from motor end.

...more

Magnetic Pump

UniBoost offers magnetic drive chemical pumps which safely handles hazardous, highly corrosive explosive and toxic chemicals. They provide safe, leak-proof service because the magnetic coupling eliminates the need for traditional sealing methods, such as mechanical seals or gland packing's, which is the main source of leakage problems on Pumps. As a result, down time and maintenance cost are greatly reduced and there are no warn seals to replace. These Pumps are available in GFR-PP and PVDF for maximum chemical resistance. Features : UniBoost magnetic drive chemical process pumps offer many benefits: 1) Minimizes exposure of your personnel to hazardous chemicals 2) Eliminates contacting seal faces which are prone to wear and leakage 3) Provides superior corrosion resistance 4) Eliminates costly seal flush systems required on all pumps with double mechanical seals. 5) Reduces downtime and maintenance costs through extended service intervals 6) Eliminates alignmentproblems inherent in direct-coupled units. Specification : Advanced Magnetic TechnologyState-of-the-art magnetic technology provides a safe and reliable pump for different applications. A magnetic coupling consists of two magnet assemblies. One is the outer assembly (the drive magnet) and other is inner assembly (the driven magnet). The outer assembly is connected to a motor and the inner assembly is directly attached to a pump impeller. When load is applied the coupling effects angularly and magnets create a force which is use to transfer torque from the motor to the impeller. This permanent coupling creates neither slippage nor induction current during rotation. There is no energy loss in this permanent magnet coupling. 'UniBoost' pumps have an inner magnet assembly which is directly molded in to the impeller.

...more

Lobe Pump

UniBoost Lobe pumps are similar to external gear pumps in operation in that fluid flows around the interior of the casing. Unlike external gear pumps, however, the lobes do not make contact. Lobe contact is prevented by external timing gears located in the gearbox. Pump shaft support bearings are located in the gearbox. Rotary pumps can handle solids (e.g., cherries and olives), slurries, pastes, and a variety of liquids. If wetted, they offer self-priming performance. A gentle pumping action minimizes product degradation. They also offer continuous and intermittent reversible flows and can operate dry for brief periods of time. Flow is relatively independent of changes in process pressure, too, so output is constant and continuous. Rotary pumps also offer superior CIP/SIP performance. Once in line, they can be cleaned without being removed. Depending on the application, it is a good idea to check with the manufacturer to make sure if a particular lobe pump meets both 3-A requirements.

...more

Industrial air pump

19,000 Per unit

High Pressure Pump

Uniboost High pressure pumps is designed with Advanced Pump Technology which ensure quality, reliability and efficiency. Our high pressure pumps are Horizontal, simplex or Triplex positive displacement plunger pumps.Design:Pump drive end assemblies are of rugged construction with high quality materials and heavy duty taper roller bearings. Bearings are lubricated by splash lubrication. Pumps are designed to permit rapid and economical maintenance, particularly regarding plunger, packing and valves are manufactured to ensure accurate alignment on reassembly. Features : > Extra Strong, Heavy Duty Power frame ensures uninterrupted smooth long life > Wide variety of valves are available to suit different pumping fluids and applications > Three piece liquid end block design avoids any possibility of block cracking > Spring loaded Plunger / Special Gland Packing always ensures leak free pumping service > Reversible valve seats double the normal life of valve seats thus become long lasting quite smooth operation. > Totally dependable, reliable and efficient performance > Easy to maintain, simple to repair and nominal maintenance cost. Specification : Fluid can be accelerated to very high velocities through a nozzle by the application of sufficient hydraulic horsepower. Hydraulic horsepower is proportional to the product of fluid pressure and the volume delivered. Fluid velocity is proportional to the pressure developed through a nozzle orifice. The impact of high pressure fluid jets can remove deposits which defy mechanical cutting tools, without any damage to underlying materials by correct selection of nozzles, accessories and power sources. The High Pressure Unit consists of the following: > High Pressure Reciprocating (Simplex / Duplex / Triplex) Pump. > Prime Mover : Electric Motor / Diesel Engine. > Mounting : Base Plate / Trolley / Trailer. > Pulley set with belts and guard or Coupling with guard. > Standard Accessories : Pressure Gauge, Pressure Regulating Valve, Safety Valve, Strainer. > Cleaning Accessories (Optional)

...more

Gear Pump

Uni boost gear pump Model “UG SS” which is self priming, foot mounting type positive displacement rotary gear pump. UGSS having all Stainless Steel (SS-316) in three piece construction with investment cast.Due to three piece construction, it can be easily cleanable and maintainable that is why it is highly used in all kind of food industries. These pumps have SS-316 Gear and shaft that are nitrated to give long life and trouble free performance. The suction and delivery connection are available in 1/2" to 6" size. These pumps can be operated up to pressure of 10 kg/cm² with 13 LPM to 2050 LPM flow capacity and has suction lift of 1m to 5m at rated speed of 1440 RPM. These pumps are designed up to maximum Viscosity of 1,00,000 SSU and maximum temperature up to 200ºc. Specification : Material of Construction Pump Body: CF8M [SS-316] Front Cover: CF8M [SS-316] Back Cover: CF8M [SS-316] Gland Cover: CF8M [SS-316] Packing: Teflon Sheet Sealing: Z Pack/ Mech. Seal Bush Bearings: Teflon Coated "DU” Mounting Bracket: C.I.Gr.-20 IS 210 Rotor/Stator Shaft: EN-57/SS-430 Key For Coupling: AISI [SS-316]

...more

End Suction Pump

Uniboost “UC” Series is a horizontal single stage, Back pull out design as per ISO 2858.Standard design is foot mounted, In this design for the facility of maintenance to easily removed without disturbing the motor form the base frame & the pump casing fixed to the pipe line. Specification : Volute Casing:One piece self venting, high efficiency, volute casing suction and discharge ends as well as the supporting feet are integrally cast in the volute casing Impeller:Closed radially impeller specially designed for low NPSH requirement. Hydraulically balanced by back vanes and for large impeller diameters by balancing holes. Shaft & Bearing:The Shaft is guided in oil lubricated bearings. The alignment of bearing is ensured by appropriate centerings and modern manufacturing methods. Shaft is of high tensile steel and accurately grounded all over. Shaft Sealing:Supplied with either asbestos or graphite packing or M seal depends on liquid. Flanges:As per ASA/BS or DIN 2533 available.

...more

Coolant Pump

Uni Boost range of immiscible pumps has been designed especially for filtering systems in the machine tool industry. The low-pressure pumps are available in different flow variants and come with a choice of bottom suction or suction from the top of the volute Features : > All coolant pumps are manufactured as per IS : 2161. > All coolant pumps are rated for continuous duty (S1) at an ambient temperature of 40'C. > Dynamically balanced rotor and impeller. > All components are manufactured and inspected on latest precision machineries and calibrated instruments to give years of maintenance free operation. > All pumps are tested as per relevant Indian Standard in latest and well equipped testing lab.

...more

Hydraulic Pumps

Hydraulic Parts

Be first to Rate

Rate This