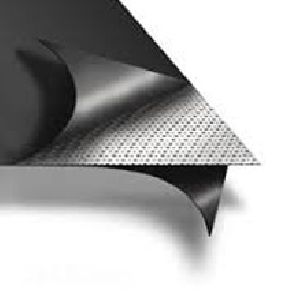

Tanged Metal Reinforced Graphite Gaskets

Tanged metal reinforced graphite Gaskets made by 98% pure exfoliated graphite reinforced a central layer of 0.1mm thickness tanged stainless steel.The graphite is compressed without the use of adhesives. Prime Features ›› Exceptional resistance to blow-out and crushing. ›› Tough and versatile composite for high pressures. ›› Strong composite construction with or without eyelets

...more

Spiral Wound Gaskets

Spiral wound gaskets are manufactured from V-shaped metal strips, spirally wound with an inlay of soft filler material between each turn. They form a very effective seal when compressed between two flanges. A V-shaped crown centered in the metal strip acts as a spring, giving gaskets greater resiliency under varying conditions. Filler and metal strip material can be changed to accommodate different chemical compatibility requirements. When spiral winding only (containing preformed metal and soft filler material) is used as a gasket, inner and outer diameters of winding are reinforced with several plies of metal without filler to give them greater stability. A spiral wound gasket may include a centering ring, an inner ring or both. The outer centering ring centers the gasket within the flange and acts as a compression limiter. The inner ring provides additional radial strength. The inner ring also reduces flange erosion and protects the sealing element. These gaskets are widely used in refineries, chemical processing plants, power generation, and a variety of valve and specialty applications. Spiral wound gaskets may be used in place of solid metal oval or octagonal API ring joint gaskets when their gasket groove is badly worn out.The spiral wound gasket industry is currently adapting to a change in the specification covering spiral wound gaskets. Previously API 601, the new specification is ASME B16.20. These specifications are very similar.

...more

Ring Type Gasket

The solid metal gasket provides an excellent mechanical joint and has almost universal acceptance in the oil, petroleum and chemical processing industries where high mechanical and thermal performance is required. The type R oval configuration is the original ring joint design and was followed by the type R octagonal which offered more specific sealing contact areas. Details of these joints are given in ASME B 16.20 and API 6A standards. The gaskets sit in a recess in the flange face having 23° angled walls. The RX joints are an unequal bevel octagonal ring, and are considered to be a pressure energized or pressure-assisted seal. The BX is also octagonal, though shorter in profile and designed to go into a recess that comes metal-to-metal when the flanges are tightened. These are used on very high pressure flanges up to 20,000 p.s.i. rating. Gasket metal should be selected to suit the service conditions and should have hardness lower than the flange metal.

...more

Metal Reinforced Soft Gaskets

When gasket width has to be narrow as in cylinder heads and exhaust manifold on internal combustion engines, compressed asbestos fibre (“CAF”) sheets and compressed asbestos-free (non-asbestos) fibre sheets are reinforced with mesh wire gauge to resist the blow out. Sheet jointing of pure exfoliated graphite are reinforced with a central layer of 0.1mm thick tanged stainless steel to give them extra strength for easy of handling and fitting. In these gaskets the graphite is compressed onto the perforated metal sheet to give a secure mechanical lock without adhesive. Extra strength to such sheets is also given by bonding a central layer of stainless steel or nickel foils.

...more

Metal Jacketed Gasket & heat Exchanger Gasket

These gaskets are specially designed and widely used for heat exchangers, autoclaves, columns, pressure vessels, valve bonnets, etc. The gaskets are manufactured from a soft, pliable filler core surrounded by a metal jacket, chemically and thermally resistant to the working conditions. Metal jacket may totally or partially enclose the filler. Metals such as soft iron, carbon steel and stainless steel are used in annealed condition to encase a soft filler material, usually non-asbestos millboard. Alternative fillers include expanded graphite, PTFE, compressed non-asbestos fibre and ceramic fibre.

...more

Lens Rings

They are widely used in high pressure applications and are resistant to overstressing. They are manufactured in accordance with DIN 2696 PN 64 to 400 and DN 10 to 300.

...more

Kammprofile Gasket

Metal gaskets with grooved faces have proved to be very effective for sealing flanged connections, and are particularly suited to applications, pressures and fluctuating conditions are encountered. Typical applications are gaskets for heat exchangers, vessels and reactors, and various flanged connection. commonly known as kammprofile gaskets, the grooves are machines in accordance with the profile specified in DIN 2697 adn are available in a range of styles and materials. non-metalic covering layers ensure that flanges are not damaged, even at high loadings, adn provide excellent sealing properties when supported by the grooved metallic gasket. kammprofile gaskets are use in heat exchangers may be fitting with grooved partition bars.

...more

Graphite Sheets

Graphite sheets contain more than 95% pure exfoliated graphite. An Ultra High Purity (99.8%) grade is available for nuclear industry applications. More care is required in handling and storage of these sheets as they get easily damaged.

...more

Corrugated Metallic Gaskets

Corrugated metallic gaskets have a corrugated metal core (normally stainless steel), with expanded graphite facings. They are used for standard pipeline duties, and heat exchangers.

...moreBe first to Rate

Rate ThisOpening Hours