Work Rolls

Depending on application these are reconditioned by weld build-up (based on chemistry of base metal) and/or are hard chrome plated. Super finishing is carried out wherever required. Various rolls such as back-up rolls, tube rollers, oiling drums, embossing rollers, inking rollers, pinch rolls and other rolls of aluminum from steel, paper, textile, aluminium, food, edible oil and other processing industries are reconditioned to their required size and profile.

...more

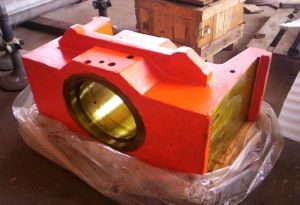

BACK UP ROLL CHOCKS

With 15 T positioner, 8m3 volume stress relieving capacity & expertise in wide range of welding made United Van Der Horst ideal for repair of Roll Chocks. Repair includes reconditioning of Bearing diameter by welding, machining followed by grinding process to maintain the required size & surface finish, maintaining parallelism of liner faces. Repair of grease lines, Repair / Modification of Bending cylinders with New sealing design.

...more

WELL CONTROL HEAD

Repairing of gates, seats, seats pockets, mono block body, threaded holes, renewal of sealing elements and pressure testing up to 21,000 PSI. Modified or OEM seals with latest technology and with different sealing profiles are available.

...more

Gate Valves

We are the main supplier of this product.

Type : Pressure Control Valves

Material : Metal

Application : Oil Fitting, Water Fitting

Automatic Grade : Manual

Number Of Way : 2way

...more

TURBO CHARGERS ROTORS

Repair of shafts by grinding, chrome plating and bringing back to standard size, dynamic balancing, etc ( including Ash Blasting wherever necessary)

...more

TURBOCHARGER CASINGS

Eroded / Worn Casings (thin walled) or even cracked ones of the turbo chargers casing can be effectively repaired by the "Cold / Fusion" method. All turbo charger casings are hydro-tested in house and classified by the certifying authority.

...more

top drives

Repair of cylinders, rods, gears, replacement of seals and other fitments, pressure testing, etc as per OEM requirements. Modified or OEM seals with latest technology and sealing profiles are available.

...more

TIE-BAR

Tie-Bar is a parts of Extrusion press / Forging Press subjected to heavy Tensile & Fatigue loading. Repair scope includes joining of broken tie-bars of size 500mm diameter & length in excess to 10000 mtrs by welding & then Finish machining as per requirements.

...more

THRUSTER JACKING CYLINDER

United Van Der Horst has successfully developed "Thruster Jacking cylinder" for Drilling Tycoon "Transcoean". Scope includes Modified Piston head with Phosphorous Bronze Guide, Modified Rod sealing arrangements for easy replacement of seals & to avoid water impregnated.

...more

Telescopic Cylinder

United Van Der Horst has successfully developed work procedure for hard chrome plating of thin walled section telescopic cylinder's Barrel & Rod. Grinding of thin walled section tubes requires special care to avoid Bulging / Uneven grinding. Wide range of custom designed fixtures made us possible deliver the goods at right quality & time. Modified/OEM make seals are also offered as per customer requirement.

...more

SUPPLY OF SPARES AND SERVICING OF YANMAR ENGINES

United Van Der Horst is the authorized representative for supply of Yanmar Engine, spare and servicing of engine.

...more

SKIDDING GEAR BOX

Repair include dismantling of gear box from RIG, replacement of damaged roller bearings, Modification of Oil seal, Repair of damaged base plate, Installation of gear box back in to Rig.

...more

SCREW-DOWN SHAFT

Used in rolling mills for gap adjustment between the roll & is subjected heavy fatigue loading : Repair scope includes repair of damaged threads, refurbishment of damaged bearing diameters by hard chrome plating.

...more

Screw Conveyor

Used in processing industries as a short distance conveyor. Repair scope includes re-sizing of flutes diameter by machining followed by grinding to maintain the required size and tolerance. Repair of Bearing diameters by Hard chrome plating. Dimensional accuracy of 0.1 mm can be easily achievable for flutes & 0.01 mm for bearing diameters.

...more

Screw Compressor

Reconditioning of internal diameters of both side bearing housing body by machining followed by weld build-up and finally finish machining to its original shape and size. Journal Bearing diameter of both the male and female screws are repaired and re-conditioned by hard chrome plating and grinding process to get the required surface finish & tolerance. Replacement of damaged bearings. Rectification of lubrication lines.

...more

rudder stock

Rudder stock is a part of Rudder system of Ships for directional control. Repair scope includes rectification of damaged / pitted surface of rudder stock as per approved WPS (welding procedure specification) from DNV / Approved certifying authority for the respective ship. High stress concentrated areas shall be taken in to consideration during welding.

...more

Rotor Shaft

Rotor Shaft is a life line of oil drilling rigs which provides rotating power to the drilling Head /tool. Repair scope includes hard chrome plating of helical flutes which provides wear resistance surface. Surface hardness of chrome plated surface shall be minimum 65 Hrc & Surface finish value less than Ra 0.3 microns. Deep dents marks / Pitting marks shall be locally repaired before hard chrome plating.

...more

Rotary Union

A Critical equipment used for supply of oil / water at pressure for rotating parts specially for Hydraulic cylinders in Rolling mills, CNC Head stocks. Repair scope includes repair of sealing diameters by Hard chrome plating, replacement of damaged bearings, Modification of sealing arrangement / replacement of seals. Testing of rotary joint at actual working conditions at given RPM.

...more

Rotary Seals

Modified or OEM seals with latest technology and sealing profile are available for rotary application like gear boxes, motors, pumps, machine can be supplied for diameters up to 2500mm and shaft speed up to 35 m/sec. seals are manufacture in different elastomers and thermoplastics as VITON, HNBR, PTFE, PEEK, etc among more than 135 different material compounds. Split seals can be supplied to reduce downtime while replacing seals. United Van Der Horst offers seals with special spring designs for optimum contact force for effective sealing which results in lower wear rate and long retention of sealing action.

...more

ROLL BENDING BLOCK (MAE-WEST BLOCK)

Repair includes repair of cylinder bore by welding machining & grinding process, Hard chrome plating of piston rods, Replacement / Modification of sealing system, Rectification of Oil paths / Drills ,Re-chasing / Re-Tapping of threaded holes, Maintaining parallism of liner faces. Load testing facility up to 250 T capacity. United Van Der Horst has also manufactured new design roll bending blocks with I.D. hard chrome plated and ground surface finish along with Low friction sealing design.

...more

ROCK BREAKER CYLINDER

Used as a Crusher cylinder in Cement plants .Repair scope includes Parting of cylinder barrel & end cover for hard chrome plating, Hard chrome plating of cylinder barrel & piston rod. Replacement of seals with Modified /OEM make. Load testing of cylinder assembly at required pressure

...more

riser pipes

Renewal of joints, repair of ring grooves as per API procedure by pre-machining, welding of SS buffer lay, SS inlay, stress reliving, finish machining, DP tests and pressure testing up to 21,000 PSI.

...more

Reach Stackers

Reconditioning of lift cylinders, steering cylinders, boom cylinders and load testing of equipment including power pack. Seals with latest technology and with modified sealing profiles are available.

...more

Water Pump

We are the main supplier of this product.

Type : Automatic

Certification : CE Certified

Weight : 20-40kg

Power Source : Electric

Usage : Deep Well Pumping

Theory : Axial Flow Pump, Centrifugal Pump

Structure : Diaphragm Pump

...moreBe first to Rate

Rate ThisOpening Hours