Roto Cone Dryer

Get Price Quote

Roto Cone Vacumm Dryer is suitable for drying of materials which cannot resist high temperature, materials which are easily oxidized, volatile materials which should be retrieved, materials that are strong irritants and poisonous in nature. The Roto Cone Dryer with improved technology integrates during operation under vacuum. The Roto Cone Dryer facilitates enhanced drying efficiency, low temperature operation and economy of process by total solvent recovery. It helps cGMP base working by achieving optimum dust control, while offering advantages of efficient charging and discharging of materials.

VACUUM TRAY DRYERS

Get Price Quote

FUNCTION Used mainly for drying of high grade, temperature and oxygen sensitive products. Highly suitable for drying hygroscopic substances, which are dried to very low residual moisture, content level. Frequently vacuum drying cabinets are the sole possibility for drying lumpy, glutinous products or products of low pomposity. CAPACITY Standard models range from 4 trays to 48 trays. SALIENT FEATURES Bodies may be of cylindrical or rectangular cross section. Both shelves and body are heated (the body to prevent internal condensation) with controlled circulation of hot water, steam or dia thermic fluid. Vacuum is drawn through large diameter ducts to minimize pressure drops and produce minimum working pressures. Both rotary and static dryers can be supplied with the following Optional ancillaries. Heater system for either pressurized hot water or dia thermic fluid. Cyclones and sleeve filters for powder recovery (for rotary dryers) Solvent recovery system with condenser and receiver, vacuum pump and ancillaries, characteristics and dimensions depending on the drying processes. Vacuum Tray dryer is the most commonly used batch dryer. They are box-shaped and loaded and unloaded via a door (two doors on the larger models). Inside are several heating plates mounted one above the other on which the product is placed in trays. The bottoms of both heating plates and trays should be as smooth as possible to permit optimal heat transfer between plates and product. The medium flowing through the heating plates is water, steam or thermal oil. The distance between the heating plates is determined primarily by the surface loading and the foaming of the product. To void retrograde condensation the cabinet walls are indirectly preheated by the heating plates. Next, the product is introduced and heated at atmospheric pressure. Only after all individual product trays reach the same temperature the cabinet is evacuated and drying can start. The preheating phase is very important in order that the drying curve and the foaming of the product is identical throughout the cabinet. During the main drying phase the vacuum is in the range of 40 to 80 mbar abs and in the final drying phase vacuums of only few mbar abs are reached. Heating temperatures are normally in the range between 800C and 1100C. Depending on product and surface load, drying takes from a few hours to 1 to 2 days. For some products the vacuum and temperature profiles are automatically controlled in order to prevent a pass over of the critical product temperature. factor in the design of drying cabinet systems. If for example vigorous foaming of the product is desired, evacuation to the operational vacuum level must take place very quickly. Vapors produced during drying are taken out direct, or via a steam jet compressor to a surface condenser in which the vapors condensate. The non-condensable vapors are extracted by the vacuum system. On completion of the drying, the product can be cooled by circulating of cooling water through the heating plates. Features: All contact parts are made out of SS304 / SS316 / SS316L quality material in GMP models and mild steel externals with stainless steel internals in standard model Hollow pad type heating shelves which are easily removable for maintenance Condenser and condensate receiver fixed on the dryer body or stand alone for remote installation Full welded skirt on vacuum dryer body for flush mounting through the wall. External fluid heating of dryer with protective panels in stainless steel or mild steel powder coated. Dedicated fluid heating and circulating systems. These can be steam or electrically heated. Fluid heating systems are available for water as well as thermic fluid (for temperature requirements above 95 oC) Validation ports and nitrogen purge nozzles Can be designed to customers specification requirements Steam sterilisable models available Double door loading available for large models Halar lined internals for corrosive applications

Best Deals from Vacuum Dryers

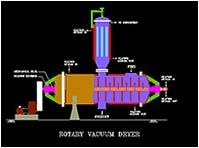

Rotary Vacuum Dryer

Get Price Quote

We are leading manufacturer and supplier of rotary vacuum dryer.typical applications- » pharmaceuticals » pasty materials » dyestuffs.

Vacuum Tray Dryer

Get Price Quote

Used mainly for drying of high grade, temperature and oxygen sensitive products highly suitable for drying hygroscopic substances, which are dried to very low residual moisture, content level. Frequently vacuum drying cabinets are the sole possibility for drying lumpy, glutinous products or products of low pompality.Capacity :- Standard models range from 4 trays to 96 trays.Bodies may be of cindrical or rectangular cross section both shelves and body are heated with controlled circulation of hot water, steam or diathermic fluid.Vacuum tray dryer is the most commonly used batch dryer. They are box-shaped and loaded and unloaded via a door ( two doors on the larger models). Inside are several heating plates is water, steam or thermal oil. The distance between the heating plates is determined primarily by the surface loading.The preheating phase is very important I order that the drying curve & the foaming of the product is identical throughout the cabinet. During the main drying phase the vacuum is in the range of 40 to 80 mbar abs & in the final drying phase vacuums of only few mbar abs are reached.The dimensioning of the vacuum system is an important factor in the design of drying cabinet systems.Available capacity :- Dryer range from 4 trays to 96 traysM.O – M.S, S.S.304, S.S.316, S.S.316L , Hallar Coated etc.Heating Media:-Electrical Heater/Steam CoilElectric & Steam coil type

VACUUM TRAY DRYERS

Get Price Quote

4 Piece (MOQ)

ROTOCONE VACUUM DRYER

Get Price Quote

They are, however, suitable for only free flowing materials, which are readily converted from slurry or wet cake to free flowing powder without exhibiting sticking or lump forming properties during the course of drying operations.

Vaccum Tray Dryer

Get Price Quote

Vacuum Tray Dryer

Get Price Quote

We are engaged in manufacturing high grade Vacuum Tray Dryer in various shapes and sizes. Our Vacuum Tray Dryer is aptly designed for drying thermal sensitive materials which can be easily resolved, degrade, or polymerized under high temperature. Sterilization of the material can be conducted before drying process as no other materials are allowed to enter once the dryer is started. Besides, it also assists in elimination of configurationally damage of drying materials. Optional : Receiver and Condenser in SS 316SS 304 steam radiator/electrical heatersValidation port is available with CensorsSkirting or wall panel that is provided with all along the body as well as vacuum chamber flangeHot water system (steam heated) with MS tank (Insulated)Insulation is provided with vacuum chamber outer surface excluding door. The insulation is enclosed and is covered with transferable SS 304 panelsCirculation pump with FLP Motors and controlsVacuum Pump (2stage water ring) consisting FLP motor Salient Features : Main Body made of thick SS 316 plateDoor thick SS 316 plate consisting heavy duty SS 316 flangeHeavy duty SS 316 flange and stiffeners availableTrays (without back folding) in SS 316 having round corners and edgesCondenser and Receiver SS 304Hollow type pads shelves with SS 316 Sheet as well as BafflesDigital Temperature controller (FLP) withExplosion Vent or rupture disc on vacuum chamberValidation Port on Body (provisional)Solenoid controlled Pneumatic operated valve located at hot water inletDigital type Vacuum gauge in vapor lineDigital Temperature Indicator at H.W. inlet & outletPressure release valve in steam lineDigital Temperature Indicator (FLP) in vapor lineSilicon Transparent gasket perfectly designed for doorLight glass provided on vacuum chamber body, door and receiverDrain valve for Vacuum chamber as well as ReceiverNitrogen purging valve and Vacuum break valve available on vacuum chamberFinish : Internal 320 grit Mirror Polish /outer 180 grit mat finishTemperature Accuracy : plus-minus 2 to 3 degree

VACUUM TRAY DRYERS

Get Price Quote

VACUUM TRAY DRYERS, double cone vacuum dryers, Conveyor Idler, Tunnel Dryer

Rotary Vaccum Dryers

Get Price Quote

A well known rotary vaccum dryers supplying company.

Vacuum Tray Dryer

Get Price Quote

All stainless steel 304 316 316L CGMP or mild steel externals with stainless steel internals (vapor and product contact parts), Hollow pad type heating shelves which are easily removable for maintenance, Condensor and condensate receiver fitted on the dryer body or stand alone for remote installation Fully welded skirt on vacuum dryer body for flush mounting through the wall, External insulation of dryer with protective panels in stainless steel or mild steel powder coated Dedicated fluid heating and circulating systems. These can be steam or electrically heated. Fluid heating systems are available for water as well as thermic fluid ( for temperature requirements above 95 degree centigrade ), Validation ports and nitrogen purge nozzles. Can be designed to customers specific requirements, Steam sterilisable models available, Double door loading available for larger models

horizontal type vacuum dryers

Get Price Quote

horizontal type vacuum dryers, Limpet Reactor, ribbon

Agitated Cylindrical Vacuum Dryer

Get Price Quote

Agitated Cylindrical Vacuum Dryer, Nitrous Oxide Gas Plants, air tray dryer

Vacuum Tray Dryer

Get Price Quote

Vacuum Tray Dryer, Fluid Bed Dryers, pharmaceutical packaging machines

Vacuum Tray Dryer

Get Price Quote

Vacuum Tray Dryer, High Shear Mixer, vacuum transfer system, air tray dryer

rotary vacuum cone dryers

Get Price Quote

rotary vacuum cone dryers, halar coating, etfe coating, pvdf coating

Vacuum Drum Dryer

Get Price Quote

Vacuum Drum Dryer, wiped film evaporator, Process Consultancy Service