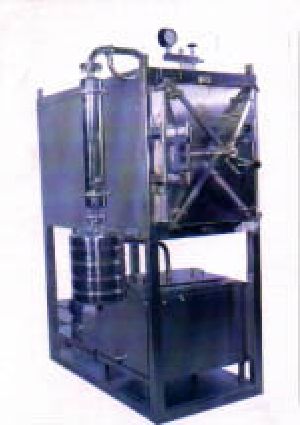

Vacuum Tray Dryer

1,150,000 - 1,450,000 Per Sets

1 Sets (MOQ)

DETAILS SPECEFICATIONS:FinishInternal - 240 Grit MirrorExternal - 180 Grit MattMOCAll Contact Part - SS 316Non-contact Part - SS 3041) VTD - 12 Trays:-Main Body 4 mm Thk:-Door 6 mm Thk:-Nos. of Heating Plates 6 + 1 Nos:-Size of Heating Plate - 825 x 825 x 28 mm:-No of Tray Per Heating Plate - 2 Nos:-Hot Plate (Top Plate 4 mm, Bottom Plate 3 mm):-Door Gasket 16 x 16 Silicon Rubber Food Grade2) Condenser - 1.5 m2Contact Part SS 316 Non-contact SS 3043) Receiver - 100 LtrsContact Part SS 3164) Tray 1.2 mm thkSize - 16" x 32" x 1.1/2," Ht.MOC - SS 316Qty. - 12 Nos5) FLP Push Button Control Panel6) PT-100 Temperature Sensor FLP7) Light FLP8) Vacuum Pump 2 Hp,Type - Water-Ring TypeMake - HBI9) Vacuum Inlet Y-Type Control Valve - 1"10) Interconnected Piping11) Hot Water Tank 150 Ltr - SS 304With Water Circulation Pump - 1 Hp.Heater - 5 KW - 2 Nos.

rotary vacuum dryers

Get Price Quote

As a celebrated Manufacturer and Supplier of Rotary Vacuum Dryers, we attempt to gain 100% customer satisfaction. Our wide range is manufactured using matchless raw material. We meet the highest parameters and norms of quality set by the industry. Designs are made by keeping several specifications in mind. The quality on offer, which is loaded with features such as high functionality and minimal maintenance, is available for economical prices.

Best Deals from Vacuum Dryers

vacuum shelf dryers

Get Price Quote

Vacuum Shelf dryers provide rapid drying of heat sensitive, air-sensitive & pyrophoric materials, or materials that require drying without agitation. Heat sensitive materials can be dried at low temperatures under vacuum, since the environmental pressure is reduced below the vapour-pressure of the contained water or solvents. Oxidation or Contamination by Air is eliminated. Recovery of expensive solvents can be virtually complete. Hollow Fibers, Medical Devices, Chemical Salts, Fine Chemicals, Dyes, Glandular Products, Pharmaceuticals and Food Extracts (Gluten, Glues, Pepsin), Rubber Explosive, etc. are ideally suited for drying in this manner. Environment Principally, Drying under vacuum is environmentally friendly because the Evaporated Solvents can easily be re-condensed. These solvents can then either be recycled or disposed of without any problem. Drying of solvents in Ex-proof ovens may solve the safety problem in the oven but not the environmental aspect. The solvent vapour is blown out of the oven through the exhaust system Furthermore, there is a risk of uncontrolled mixture formation. Features : A major design feature incorporated in this series of vacuum dryers is the placement of all shelf and manifold connection outside of the chamber, avoiding the possibility that leaks might develop within a chamber and contaminate the product being dried. This feature also simplifies the maintenance of these connection by making access to them more convenient. Charge temperature measuring facility provides exact picture of the process. It measures the temperature directly at charge (material). A PT-100 Temp. Sensor enters the vacuum chamber via connection at the top Rear. "SANDWICH" Type High Thermal efficiency Stainless Steel Shelves with the heat transfer fluid circulation. Even heat distribution through whole shelf surface by baffles within shelves. Chamber walls are heated externally to prevent condensation on the internal walls. Rounded edges in walls shelves and product trays in order to facilitate cleaning and prevent accumulation of dry product residue and practical formation

Vacuum Tray Dryer

950,000 Per Piece

Vacuum Tray Dryer comprises a precision designed and highly functional range of Vacuum Tray Dryer (VTD) that find suitability in the drying of thermal sensitive materials under higher temperature. Coming with the possibility of sterilization prior to the drying process, these static vacuum dryer eliminates configuration damages of drying materials and is suitable for use in industry sectors like pharmaceutical, chemicals, and foodstuff.

Vacuum Tray Dryer

Get Price Quote

We are vacuum tray dryer manufacturer in India . The most popularly known and used batch dryer is a vacuum dryer and we are a well-known Vacuum Tray Dryer Exporter. They are shaped in a box structure. The medium flowing through the heating plates is water, steam or thermal oil. The gap between the heating plates is invented primarily by the surface loading and the foaming of the product. To void retrograde condensation the cabinet walls are indirectly preheated by the heating plates. We, Vacuum Tray Dryer Exporter offer you this Vacuum Tray Dryers at very reasonable rates Vacuum Tray Dryer works under vacuum conditions on the conduction principle, known as vacuum tray dryer working principle. Store the products inside the dryer, which consists of multiple shelves and trays. The topmost frame is a dummy shelf placed there to ensure proper heating and prevent the dried powder from escaping into the solvent extraction system. Brackets are constructed hollow with baffles cum stiffeners placed in between shelves. Every shelf has an inlet and outlet nozzle connected to an inlet and outlet header through these nozzles. ADVANTAGES Very efficient heat sensitive Materials can be dryers in containers or enclosures.The average drying temperature is much lower than standard dryers Heat transfer throughout the body helps in the quick-drying of larger surface areas. Dries considerable moisture as compared to traditional dryers Quality of dries material is beer than that of the regular dryers SALIENT FEATURES Stainless steel construction (SS 316L/316/304) Easily removable hollow pad type heating shelves Dedicated fluid heating and circulating systems The thermal efficiency of 60% to 80% Provision for Explosion Vent / Rupture Disc on body & Validation Port on Body On Chamber Vacuum break valve is provided High-quality interlocking for doors to the chamber Uniform heating flow Branded immersion heaters Heavy-duty MS/SS door fied on hinges Single and double doors (for large models) Complete automation w/ PLC controls (Op

Vacuum Tray Dryer

850,000 Per Unit

1 Unit (MOQ)

Rotary Vacuum Dryer

90,000 Per unit

Vacuum Tray Dryer

Get Price Quote

We supply Tray Dryer that is adequately designed by our designers and adroit personnel who take every care in the fabrication of a durable and highly efficient range of machines. Available in various models such as 12 trays, 24 trays, 48 trays, 96trays, these are high in performance and low on maintenance. The major problem in calculations on real dryers is that conditions change as the drying air and the drying solids move along the dryer in a continuous dryer, or change with time in the batch dryer. Such implications take them beyond the scope of the present book, but the principles of mass and heat balances are the basis and the analysis is not difficult once the fundamental principles of drying are understood. Obtaining adequate data may be the difficult part. In tray dryers, the food is spread out, generally quite thinly, on trays in which the drying takes place. Heating may be by an air current sweeping across the trays, by conduction from heated trays or heated shelves on which the trays lie, or by radiation from heated surfaces. Most tray dryers are heated by air, which also removes the moist vapours.

Vacuum Tray Dryer

400,000 Per Piece

ROTOCONE VACUUM DRYER

Get Price Quote

ROTOCONE VACUUM DRYER, blenders, Isolators, Vaccum Tray Dryer

Vacuum Tray Dryer

Get Price Quote

Vacuum Tray Dryer, Rapid Mixer Granulator, Inline Homogeniser Mixer

vacuum dryers

Get Price Quote

vacuum dryers, Milling Machine, Colloid Mill Machine, Dryer Machine