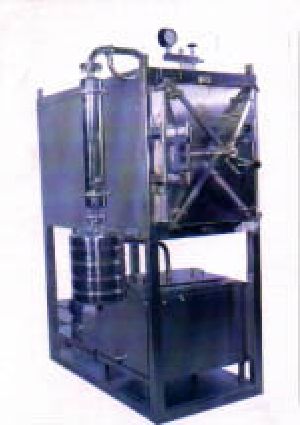

Rotary Vacuum Dryer

Get Price Quote

The drying in a Rotary vacuum dryer is a batch operation under vacuum. It is possible to dry heat sensitive materials at well below boiling points of water and solvents. Drying time depends on material being dried, amount of solvent or water to be removed, desired final moisture content, permissible jacket temperature etc. The dryer is available in sizes ranging from 100 liters to 20,000 liters gross volume. The volume of wet material loaded into the dryer is usually restricted to 40-45% of gross volume.Rotary vacuum dryer has some typical applications in pharmaceuticals, organic chemicals, pasty materials, insecticides, pesticides, solvent recovery, dye intermediates, dyestuffs and in others industries.Material of Construction (MOC) Offered : - CS (IS 2062 Gr A/B, SA 516 Gr 60/70, BQ), SS 316, SS 304, SS 316 L, SS 304 L. SS 310, MONEL, INCONEL, TITANIUM, HASTALLOY, PP/FRP ETC.Features : Equipped with different designs of agitators depending on the material to be dried. Unique quick opening discharge valve permits direct packing of dry product into bags or drums. Breaker rods are provided to prevent lump formation and allow quick and complete drying. Shaft sealing by mechanical seals is also available. N2 pulse jet dust filter (self cleaning type).

rotary vacuum dryers

Get Price Quote

As a celebrated Manufacturer and Supplier of Rotary Vacuum Dryers, we attempt to gain 100% customer satisfaction. Our wide range is manufactured using matchless raw material. We meet the highest parameters and norms of quality set by the industry. Designs are made by keeping several specifications in mind. The quality on offer, which is loaded with features such as high functionality and minimal maintenance, is available for economical prices.

Best Deals from Vacuum Dryers

ROTOCONE VACUUM DRYER

Get Price Quote

1 Piece (MOQ)

ROTOCONE VACUUM DRYER

500,000 - 4,000,000 Per Piece

1 Piece (MOQ)

Rotary Vacuum Dryer is suitable for drying of materials which cannot resist high temperature, material which are easily oxdised, volatile materials which should be retrieved, materials which are strong irritants and poisonous in nature. Rotary Vacuum Dryer with the improved technology integrates during operation under vacuum. The Rotary Vacuum Dryer facilitates enhanced drying efficiency, low temperature operations and economy of process by total solvent recovery. It helps cGMP based working by achieving optimum dust control, while offering advantages of efficient charging and discharging of materials. The drying unit equipped with lump breakers initially breaks large lumps and subsequently powders them (in single cone). The rotary action of the dryer together with mechanical action of the breakers, cuts down drying time and gives a lump free product.ADVANTAGES : (Pharmachem Cosmetics Industries) Reduces drying time Eliminates need for re-drying of lumps Handling and exposure of final product is avoided Gives uniformity size dry product System can process crystalline or amorphous powders which are prone for lumps Easy to clean internal surface, thus ensuring purity of product Optimum and continuous vacuum maintenance during process Uniform material shuffling over the heated contact surface of the cone

Vacuum Tray Dryer

1,150,000 - 1,450,000 Per Sets

1 Sets (MOQ)

DETAILS SPECEFICATIONS:FinishInternal - 240 Grit MirrorExternal - 180 Grit MattMOCAll Contact Part - SS 316Non-contact Part - SS 3041) VTD - 12 Trays:-Main Body 4 mm Thk:-Door 6 mm Thk:-Nos. of Heating Plates 6 + 1 Nos:-Size of Heating Plate - 825 x 825 x 28 mm:-No of Tray Per Heating Plate - 2 Nos:-Hot Plate (Top Plate 4 mm, Bottom Plate 3 mm):-Door Gasket 16 x 16 Silicon Rubber Food Grade2) Condenser - 1.5 m2Contact Part SS 316 Non-contact SS 3043) Receiver - 100 LtrsContact Part SS 3164) Tray 1.2 mm thkSize - 16" x 32" x 1.1/2," Ht.MOC - SS 316Qty. - 12 Nos5) FLP Push Button Control Panel6) PT-100 Temperature Sensor FLP7) Light FLP8) Vacuum Pump 2 Hp,Type - Water-Ring TypeMake - HBI9) Vacuum Inlet Y-Type Control Valve - 1"10) Interconnected Piping11) Hot Water Tank 150 Ltr - SS 304With Water Circulation Pump - 1 Hp.Heater - 5 KW - 2 Nos.

ROTOCONE VACUUM DRYER

200,000 Per Unit

RCVD

Get Price Quote

Rotary Double Cone Vacuum Dryer Rotating Cone With Vacuum Dryer is high precision low temperature vacuum drying. The Rotated Double Cone Vacuum Dryer’s suitable for drying the material which operates at low temperature, easily oxidized, poisonous in nature. It has high efficiency heat transfer and high speed drying which save energy. Raw materials are dried uniformly and have good quality at low temperature

Vacuum Tray Dryer

Get Price Quote

Vacuum Tray Dryer, offered by us, is manufactured using quality approved components and highly advanced techniques keeping in mind the set industry standards. Tested using the latest technique’s, our Vacuum Tray Dryer is the perfect option on which buyers can easily rely. We are one of the prominent Manufacturers and Suppliers of Vacuum Tray Dryer. It can be obtained from us in small as well as bulk quantities. Details : We are instrumental in providing to our valuable customers excellent quality Tray Dryers which are available with following Features : Models available 6, 12, 24, 48, 96 & 192 trays. Double wall construction. Rigid s.s. frame work. Glass wool insulated. Heating media - electric / steam for uniform drying. Unit with air inlet, air filter. Adjustable damper (outlet). Single insulated & self locking door, one fan for air circulation inside the area. (flame proof motor available as option). MOC S.S 304 / 316 / 3161. Sophisticated control panel with on / off push buttons, indicating lamps.

Rotary Vacuum Dryer

Get Price Quote

Rotary Vacuum Dryer has some usual applications in organic chemicals, pharmaceuticals, pasty materials, insecticides, pesticides, solvent recovery and in others industries. We are a noteworthy Rotatory Vacuum Dryer Manufacturer, Exporter and Supplier in Maharashtra (India). We produce a highly functional and precision based range of Rotatory Vacuum Dryer by using high quality construction materials and advanced technology in compliance with the set industrials norms and standards. Customers can avail our product at the most reasonable prices.Working : The drying in a rotary vacuum dryer is a batch operation under vacuum. It is possible to dry heat sensitive materials at well below boiling points of water and solvents. Drying time depends on material being dried, amount of solvent or water to be removed, desired final moisture content, permissible jacket temperature etc. The dryer is available in sizes ranging from 100 liters to 20,000 liters gross volume. The volume of wet material loaded into the dryer is usually restricted to 40-45% of gross volume. Features : N2 pulse jet dust filter (self-cleaning type) Equipped with different designs of agitators depending on the material to be dried. Unique quick opening discharge valve permits direct packing of dry product into bags or drums. Breaker rods are provided to prevent lump formation and allow quick and complete drying Shaft sealing by mechanical seals is also available Material of Construction (MOC) Offered : CS (IS 2062 Gr A/B, SA 516 Gr 60/70, BQ) SS 316, SS 304 SS 316 L SS 304 L. SS 310 Monel Inconel Titanium Hastalloy PP/FRP etc

cGMP Nauta Vacuum Dryer

Get Price Quote

Rotocone Vacuum Dryer, Chemical Reactor

Get Price Quote

We offer rotocone vacuum dryer, chemical reactor. aries engineers make rotocone vacuum dryers are multipurpose drying unit that are extremely useful for uniform and low temperature drying of heat sensitive chemicals, pharmaceutical formulations, fine chemicals etc. It has double conical vessel with rotating system and vacuum solvent recovery system. As the dryer is rotating, there is no charring or retention of product. The result is that one can change the material to be dried without much a do. The rotocone vacuum dryers rotates at a very low speed (5 to 15 rpm) and thus has very low wear and tear and requires very little maintenance. This machine is ideal for crystalline products, granuals used in chemical, pharmaceutical and food industries.

Roto Cone Dryer

Get Price Quote

Rotocone Vacuum Dryer is suitable for drying of materials which cannot resist high temperature, Material which are easily oxidized, volatatile materials which should be retrieved, materials strong irritant and poisonous in nature. The roto-cone dryer with improved technology integrates during operation under vacuum. The roto-cone dryer facilities enhanced drying efficiency, low temperature operation and economy of process by total solvent recovery. It helps cGMP based working by achieving optimum dust control, while offering advantages of efficient charging and discharging of materials. The drying unit equipped with lump breakers initially breaks large lumps and subsequently powders them(in single cone). The rotary action of the dryer together with mechanical action of the breakers cuts down drying time and gives a lump free product. Raw materials are charged as a batch & is subjected to indirect heating while undergoing rotary action. The conical shape of the dryer ensures efficient circulation of hot liquid heating media. The drying operation is being at low temperature under vacuum that is why it is economical and effective for drying pharmaceutical, temperature sensitive or easily oxidizable products. When the solvent is present in the wet powders, the recovery of solvent is easily possible.

Vacuum Tray Dryer

Get Price Quote

We are offering vacuum tray dryer. Models available 6,12,24,48,96,& 192 trays double wall construction rigid s.s.framework glasswool insulated steam for uniform drying moc s.s. 304/316/316l sophisticated control panel with on / off push buttons, indications lamps.

Vacuum Tray Dryers - 02

Get Price Quote

We are one of the most diligent Vacuum Tray Dryers manufacturers and suppliers located in India. Our vacuum tray dryer system carries high efficiency for drying high grade temperature. Moreover you can buy these vacuum tray dryers from us on very reasonable rates.

Vacuum Tray Dryer

950,000 Per Piece

Vacuum Tray Dryer comprises a precision designed and highly functional range of Vacuum Tray Dryer (VTD) that find suitability in the drying of thermal sensitive materials under higher temperature. Coming with the possibility of sterilization prior to the drying process, these static vacuum dryer eliminates configuration damages of drying materials and is suitable for use in industry sectors like pharmaceutical, chemicals, and foodstuff.

conical vacuum dryer

Get Price Quote

Vacuum Tray Dryer

850,000 Per Unit

1 Unit (MOQ)

vacuum shelf dryers

Get Price Quote

Vacuum Shelf dryers provide rapid drying of heat sensitive, air-sensitive & pyrophoric materials, or materials that require drying without agitation. Heat sensitive materials can be dried at low temperatures under vacuum, since the environmental pressure is reduced below the vapour-pressure of the contained water or solvents. Oxidation or Contamination by Air is eliminated. Recovery of expensive solvents can be virtually complete. Hollow Fibers, Medical Devices, Chemical Salts, Fine Chemicals, Dyes, Glandular Products, Pharmaceuticals and Food Extracts (Gluten, Glues, Pepsin), Rubber Explosive, etc. are ideally suited for drying in this manner. Environment Principally, Drying under vacuum is environmentally friendly because the Evaporated Solvents can easily be re-condensed. These solvents can then either be recycled or disposed of without any problem. Drying of solvents in Ex-proof ovens may solve the safety problem in the oven but not the environmental aspect. The solvent vapour is blown out of the oven through the exhaust system Furthermore, there is a risk of uncontrolled mixture formation. Features : A major design feature incorporated in this series of vacuum dryers is the placement of all shelf and manifold connection outside of the chamber, avoiding the possibility that leaks might develop within a chamber and contaminate the product being dried. This feature also simplifies the maintenance of these connection by making access to them more convenient. Charge temperature measuring facility provides exact picture of the process. It measures the temperature directly at charge (material). A PT-100 Temp. Sensor enters the vacuum chamber via connection at the top Rear. "SANDWICH" Type High Thermal efficiency Stainless Steel Shelves with the heat transfer fluid circulation. Even heat distribution through whole shelf surface by baffles within shelves. Chamber walls are heated externally to prevent condensation on the internal walls. Rounded edges in walls shelves and product trays in order to facilitate cleaning and prevent accumulation of dry product residue and practical formation

Rotary Vacuum Dryer

Get Price Quote

Vacuum Tray Dryer

Get Price Quote

Vacumm Tray Dryer is suitable for drying of thermal sensitive materials easily resolved, polymerized or deteriorated under higher temperature. Sterilization can be conducted prior to the drying process, during which no matter is allowed to enter the product. Static vacuum dryer eliminates the configuration damage of the drying materials, there fore widely used in pharmaceutical, chemicals and foodstuff etc,.Salient features Available in different models with options for 12, 24, 48 and 96 trays. Main Body/Vacuum chamber thick SS 316 plate with heavy duty SS 316 flange and stiffeners. Door thick SS 316 plate (Hemisphere shape) with heavy duty SS 316 flange. Shelves hollow type pads with SS 316 sheet and baffles. Condenser (shell & tube) & receiver SS 304 with isolation valve and flow glass in between to monitor condensation. Trays in SS 316 rounded corners and edges. Explosion vent/ rupture disc on vacuum chamber. Pressure release valve in steam line. View and light glass provided on vacuum chamber door. Silicon transparent gasket for door. Nitrogen purging valve provided on vacuum chamber. Vacuum break valve provided on vacuum chamber. Finishing : Internal 320 grit mirror polish and outer 180 grit mat finish.

Vacuum Dryer - Multistage Evaporating Plant

Get Price Quote

Vacuum Dryer - Multistage Evaporating Plant or vacuum dryers with rotor steam or wateroil heated with surfaces from 30 to 400 sqm. in the following executions :Single or multistage evaporating plants and with mechanical compression of vapours.

Vacuum Tray Dryer

Get Price Quote

Vacuum Tray Dryer is used mainly for drying of high grade, temperature and oxygen sensitive products. Vacuum Tray Dryer is highly suitable for drying hygroscopic substances, which are dried to very low residual moisture, content level.

Double Cone Vacuum Dryer

Get Price Quote

We offer highly efficient Double Cone Vacuum Dryer that is constructed using high-grade materials and used for drying of heat sensitive materials that are used in the chemical and pharmaceutical industry. Our Double Cone Vacuum Dryer consists of a conical cylinder along with a jacket for the purpose of steam or oil heating. The indirect heating process is carried out under vacuum and recovery of solvent becomes possible by condensing the vapor generated during the operation. The Double Cone Vacuum Dryer rotates at a slow RPM in order to ensure gentle agitation of the entire mass.

VACUUM TRAY DRYERS

Get Price Quote

FUNCTION Used mainly for drying of high grade, temperature and oxygen sensitive products. Highly suitable for drying hygroscopic substances, which are dried to very low residual moisture, content level. Frequently vacuum drying cabinets are the sole possibility for drying lumpy, glutinous products or products of low pomposity. CAPACITY Standard models range from 4 trays to 48 trays. SALIENT FEATURES Bodies may be of cylindrical or rectangular cross section. Both shelves and body are heated (the body to prevent internal condensation) with controlled circulation of hot water, steam or dia thermic fluid. Vacuum is drawn through large diameter ducts to minimize pressure drops and produce minimum working pressures. Both rotary and static dryers can be supplied with the following Optional ancillaries. Heater system for either pressurized hot water or dia thermic fluid. Cyclones and sleeve filters for powder recovery (for rotary dryers) Solvent recovery system with condenser and receiver, vacuum pump and ancillaries, characteristics and dimensions depending on the drying processes. Vacuum Tray dryer is the most commonly used batch dryer. They are box-shaped and loaded and unloaded via a door (two doors on the larger models). Inside are several heating plates mounted one above the other on which the product is placed in trays. The bottoms of both heating plates and trays should be as smooth as possible to permit optimal heat transfer between plates and product. The medium flowing through the heating plates is water, steam or thermal oil. The distance between the heating plates is determined primarily by the surface loading and the foaming of the product. To void retrograde condensation the cabinet walls are indirectly preheated by the heating plates. Next, the product is introduced and heated at atmospheric pressure. Only after all individual product trays reach the same temperature the cabinet is evacuated and drying can start. The preheating phase is very important in order that the drying curve and the foaming of the product is identical throughout the cabinet. During the main drying phase the vacuum is in the range of 40 to 80 mbar abs and in the final drying phase vacuums of only few mbar abs are reached. Heating temperatures are normally in the range between 800C and 1100C. Depending on product and surface load, drying takes from a few hours to 1 to 2 days. For some products the vacuum and temperature profiles are automatically controlled in order to prevent a pass over of the critical product temperature. factor in the design of drying cabinet systems. If for example vigorous foaming of the product is desired, evacuation to the operational vacuum level must take place very quickly. Vapors produced during drying are taken out direct, or via a steam jet compressor to a surface condenser in which the vapors condensate. The non-condensable vapors are extracted by the vacuum system. On completion of the drying, the product can be cooled by circulating of cooling water through the heating plates. Features: All contact parts are made out of SS304 / SS316 / SS316L quality material in GMP models and mild steel externals with stainless steel internals in standard model Hollow pad type heating shelves which are easily removable for maintenance Condenser and condensate receiver fixed on the dryer body or stand alone for remote installation Full welded skirt on vacuum dryer body for flush mounting through the wall. External fluid heating of dryer with protective panels in stainless steel or mild steel powder coated. Dedicated fluid heating and circulating systems. These can be steam or electrically heated. Fluid heating systems are available for water as well as thermic fluid (for temperature requirements above 95 oC) Validation ports and nitrogen purge nozzles Can be designed to customers specification requirements Steam sterilisable models available Double door loading available for large models Halar lined internals for corrosive applications

Vacuum Tray Dryer

550,000 - 750,000 Per Unit

1 Piece (MOQ)

Vacuum Tray Dryer

Get Price Quote

Rotary Vacuum Paddle Dryer

Get Price Quote

Rotary Vacuum Paddle Dryers is utilized in varied industries to extract and obtain dry powder either from solutions or wet cake. Operational efficiency is high and the costs incurred are low with this dryer when compared to other dryers in the market. The mechanism, involves a closed system wherein hot water, steam, or hot fluid is used as a heating medium within the jacket, in the hollow paddle as well as in the hallow shaft. This paddle dryer includes vacuum pump, condenser, receiver and dust collection. Wet feed receives good heat transfer with the constant agitation triggering heated rotating paddles and minimum clearance between scrapers and heated walls. This process gives rise to the evaporation of moisture or solvent, which makes the wet material dry to the essential level. Vacuum is used to remove the vapors that are formed already. Further, the dust problems are eradicated with the absence of large air flows, which also results in low energy consumption. These vacuum paddle dryer (RVPD) are highly appreciated in the market. FEATURES : Drying optimization is a process that is carried out by means of external and internal heating. The large heat transfer area available on the wide paddles and hollow shaft enable and equip maximum heat transfer efficiency to the product. External heating is generated through jacket or limpet coils, while internal heating through a hollow shaft, along with a set of hollow paddles. These hallow paddles are equipped with scrapers that have very low gap from wall in order to maximize heat transfer. Scrapers move material to all parts of the dryer and additionally help in discharging the material. There is a hollow rotating agitator shaft that imparts heat to the product and scrapes the shell wall tumbles. This facilitates for maximum heat transfer and discharge product whenever required. Mechanical seals at Shell ends/Stuffing Box. The vessel is well designed to take temperature stresses in the process of vacuum drying. Thereby, there is low power consumption with the use of helical bevel gear box. Special floating bearing design to combat temperature stresses. So as to remove the condensate formed by steam heating in the hallow shaft, special rotary joints are also designed to introduce heating media in the hollow shaft. Product Filter is very efficiently used to arrest valuable product carried away with the vapors in a filter bag. The arrested product particles are thrown back into the dryer by reverse flow of pulsating air. Generally, the product filters are heated to avoid condensations of vapors in the filter bag. User friendly discharge valve design provides vacuum tight closing when the material is processed. The quick opening facility lever facilities filling of bags when material discharge and packed. Breaker bars are incorporated in the RVPD to break the lumps when the product forms lumps at some stage in drying process. Insulation with Cladding will provide on heating jacket/Limpet coil Rotary Vacuum Paddle Dryers (RVPD) is a cylindrical jacketed vessel with a central agitator having specially designed blades. The blades of this Rotary Vacuum Paddle Dryer (RVPD) are so designed that they sweep the entire internal surface and at the same time turn the material so that all the particles are come in contact with the heated surface.GMP construction - Cylindrical, horizontal vessel with flat welded rear cover and a hinged flat front door opening up over the entire vessel diameter. With the door open the internals of the machine are fully accessible for cleaning and inspection purposes All surfaces in contact with the product such as the vessel, rear cover, front door, agitator and vapor filter are heated, providing very efficient heat exchange. To provide for good heat exchange and discharge characteristics the cylindrical vessel, the rear cover, the front door and the agitator are machined to assure the smallest possible tolerances between agitator and vessel walls. The agitator is installed at the rear of the dryer, supported on one side of the vessel only.The agitator is designed to meet the requirements of this particular dryer type to assure good and even mixing action throughout the dryer volume, also in reverse operation. The agitator provides very good emptying characteristics, and at the same time reduces friction onto the product to a minimum to prevent local overheating as well as to prevent directional thrust or local product compression. A double mechanical seal is installed on the rear cover, well accessible for cleaning and maintenance purposes. A spacer in between the seal and the agitator drive permits removal of the seal without disassembling the drive. Dry or wet running mechanical seals may be installed. The central agitator shaft is supported on the one end bearings housed in bearing housing in such a way that the alignment remains always intact. This central agitator is driven by means of a Motor & Gear box through the bull Gear. The horizontal shell is jacketed to heat the shell with steam / hot water or any other thermal fluid. Limpet coil is provided instead of jacket if the heating media is fluid.A Dust Catcher consisting of bag filter is provided on the top to prevent the losses of material particles after the drying process.A Condenser of adequate heating surface area is provided wherein the evaporated vapors are condensed and these condensed vapors are then collected in the receiver of suitable capacity, placed beneath the condenser.A Vacuum Pump of adequate capacity is provided & fitted to the receiver of these rotary vacuum dryers to create the vacuum in the dryer shell through the Receiver, Condenser and Dust Catcher. SALIENT FEATURES OF ROTARY VACUUM DRYERS (RVD) : Very suitable for drying materials which are heat sensitive, as low temperature for drying can be maintained by high vacuum Lowest energy consumption compared to any other batch type dryer due to higher differential temperatures. Higher Thermal Efficiency. Almost 100% recovery of solvents. Heating Temp.: From 30°C to 300°C. Evaporation Rate : 4.12 Kg/ HrlSq. Meter of Heating surface area of water at heating temperature of 100°C. Limpet coil could be provided instead of jacket if the heating media is fluid. Breaker bars of approximately same length as dryer shell can be provided if lump formation is expected during drying

Continuous Vacuum Band Dryer

Get Price Quote

Vacuum band drye are used to dry heat sensitive products in a continuous flow. It is a cylindrical or rectangular chamber which is under vacuum from the inside. Vacuum band dryer contains a number of synthetic or metallic wire mesh paddle-dryer-manufacturers.htmls which pass over steam or hot water heated elements. The product gets spread equally on the paddle-dryer-manufacturers.html at the feed point of the machine. High efficiency heating plates in direct contact with the surface ensure maximum heat transfer and even drying. The dryer comes with different capacities ranging from a single vacuum band dryer up to multiple depending upon the required heating surface area, The dryer is supplied complete with heating system, vacuum pump, solvent condensor and piping. APPLICATION : Eenzyme Food paste, Pharmaceutical products, Fruits & Vegetables Protein Extracts Gelatin Matted Milk Highly Viscous Liquids Products containing a certain amount of sugar.

Double Cone Vacuum Dryer

Get Price Quote

Location of Gland sealing arrangement right next to the shell. Positive circulation of Hot Water is ensured with no chances of by-pass or short circuiting No Rotary Pressure Joints are used (which are the potential source of leakages). Inert gas purging pulsing is possible with vacuum "ON" (No need to shut-off Vacuum for Nitrogen admission).

Vacuum Tray Dryer

Get Price Quote

Used mainly for drying of high grade, temperature and oxygen sensitive products highly suitable for drying hygroscopic substances, which are dried to very low residual moisture, content level. Frequently vacuum drying cabinets are the sole possibility for drying lumpy, glutinous products or products of low pompality.Capacity :- Standard models range from 4 trays to 96 trays.Bodies may be of cindrical or rectangular cross section both shelves and body are heated with controlled circulation of hot water, steam or diathermic fluid.Vacuum tray dryer is the most commonly used batch dryer. They are box-shaped and loaded and unloaded via a door ( two doors on the larger models). Inside are several heating plates is water, steam or thermal oil. The distance between the heating plates is determined primarily by the surface loading.The preheating phase is very important I order that the drying curve & the foaming of the product is identical throughout the cabinet. During the main drying phase the vacuum is in the range of 40 to 80 mbar abs & in the final drying phase vacuums of only few mbar abs are reached.The dimensioning of the vacuum system is an important factor in the design of drying cabinet systems.Available capacity :- Dryer range from 4 trays to 96 traysM.O – M.S, S.S.304, S.S.316, S.S.316L , Hallar Coated etc.Heating Media:-Electrical Heater/Steam CoilElectric & Steam coil type