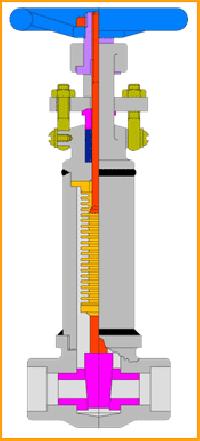

Forged Steel Gate Valve

Get Price Quote

VALTECH” compact design & high pressure, Forged Steel Gate Valves are designed and manufactured with reference to standard API 602 for small Pipelines up to 50NB. They are available in Threaded as well as Socket Weld ends. Hard Faced Trim material ensures perfect Sealing and longer life. Lapped Back Seat is provided to ensure re-packing/replacing of Gland Packing in stream, when the Valve is in full open condition which ensures maximum safety, convenience and economy. If required, Valves can be offered under any THIRD PARTY INSPECTION. “VALTECH” Gate Valves are available in various materials like Forged Carbon Steel conforming to ASTM-A-105, Forged Alloy Steel like ASTM-A-182-F11, F22 and Forged Stainless Steel like ASTM-A-182 F304, F304L, F316 and F-316L. Size range starts from 15 NB through 50NB and pressure rating up to ANSI 2500#.

Swing Check Valves

Get Price Quote

Manufacturing Facilities: State-of-the art production facilities in Kundaim, Goa and in Pune, Maharashtra; spread over a lakh of sq. feet in aggregate I SO, 9001-2008 certified operations. Facility accredited under CE marking, ASME, U,PP and R Stamps as well as PED. Facility and products approved by Global Engineering Consultants and Contracting companies. Well-equipped testing and inspection facilities. World class finishing and packagind processes Well documented and appropriately preserved inventories. And above all competent and caring human resources. Ball Valves Floating ball Valves: Carbon steels, stainless steels and variety of alloy steels. Two piece and three piece designs. Soft seated and metal seated; 150, 300 and 600 lbs in cast version, 800 lbs in Forged Bar. Full Bore and reduced bore; sizes ½" to 8". Trunnion-mounted Ball Valves Carbon steels, stainless steels and variety of Alloy steels. Two piece and three piece designs. Soft seated and metal seated. 150, 300 and 600 lbs in cast version- in forged Sizes: 3" to 24" Butterfly Valves Wafer, Lugged and Flanged: - Cast iron, Cast Steel and Stainless Steel Body; Moulded seat, Pressure classes 125 lbs and 150 lbs. Sizes: 3" to 24" Triple-offset, Metal seated: - Carbon steels, Stainless Steels and variety of Alloy steels, Pressure classes 150, 300 and 600 lbs Sizes: 3" to 24" Gate, Globe and Check Valves In cast version: Carbon Steels and Stainless Steels, 150, 300 and 600 lbs sizes ½" to 12" In Forged: Carbon Steels, Stainless Steels and Alloy Steels, 150 to 2500 lbs sizes ½" to 2"

Best Deals from Check Valves

Dual Plates Check Valve

Get Price Quote

1000 Piece (MOQ)

One-way Check Valve

Get Price Quote

Check Valve

Get Price Quote

We fabricate a wide range of Check Valves which includes swing check valves, ball check valves and many more valves. These valves manufactured by us are made from the best of the metals. The designs of these valves are completely unique in comparison to other available in the market which directly increases its efficiency. These valves even work properly under tough and unyielding condition. These things make our products stand a way ahead of others available. We have a special quality analysis department which checks the quality. This has made us the most prominent wafer check valves manufacturer and suppliers in India.Swing Check Valves are having Bolted cover, Swing type disc. These valves are used to prevent flow reversal in piping systems. They are suitable for service in horizontal (flow up through valve only) piping runs. Swing Check Valves have low pressure drop and are best suited for moderate velocity applications. Correct sizing of swing check valves is important. Either too low a line velocity or too high a velocity can damage valve internals and shorten valve life.Swing Check Valves are suitable for all service media. Valves can also be supplied with counter weights and dash pot arrangement depending upon the condition and request. Standards Applicable : Design Standard : BS 1868/API-6D Testing Standard : API 598/BS EN 12266 -1 Face to Face :ASME B 16.10 End Connection : Flanged End : ASME B 16.5 Butt Weld End : ASME B 16.25 Pressure Temperature : ASME B 16.34 Material Structure : End Connection : Flanged end raised face, Butt weld end, RTJ, etc. Shell : WCB, WC1, WC6, WC9, LCB, LCC, LC3, C5, C12, CF8, CF8M, CF3, CF3M, CF8C, CN7M, CD4MCu, Hastalloy, Inconel, Duplex Stainless Steel. Trim : 13% Cr. Steel, 304, 304L, 316, 316L, 321, 347, Monel, Duplex Stainless steel.

Non Return Valves

Get Price Quote

Forged Steel Bellow Seal Gate Valves S/W

Get Price Quote

We manufacture and export grade Forged Steel Bellow Seal Gate Valves S/W with complimentary accessories. It has won critical acclaims for its technically engineered structure. Technical DataValve Designed to BS-5352 (Reduced Bore)Valve Tested to API- 598 / BS- 5146Socket Weld Ends to ANSI-B-16.11Butt Weld Ends to ANSI-B-16.25Screwed Ends to ANSI-B-1.20.1 (NPT)End to End as per Manufacturers SpecAccessoriesHand Wheel Locking ArrangementActuator Mounted ValveNotesValve upto 50mm NB are from ForgingOptional Full port Design upto 40mm NBAlso Manufatured in Grade F 304L / F 316LOptional Stellited Seat & PlugOptional Screwed Ends Optional Butt Weld EndsOptional Socket Weld EndsAlternate Bellow Material= HC-276/ Inconel-625

DUAL PLATE CHECK VALVE - METAL SEATED

Get Price Quote

Double Controlled Fire Hydrant Valve

6,000 Per Piece

Dual Plate Wafer Check Valves

Get Price Quote

We are leading suppliers of dual plate wafer check valves which help in reducing industrial check valves cost substantially because they are quite economical. These are two port valves that allow one fluid to enter and the other fluid to leave. We have a diverse range of these valves which meet all the quality standards. applications : in various types of pumps like piston pumps and metering pumpsin industrial processeschemical power plantsirrigation sprinklers and drip irrigation emitters range : sizes from 2” to 100” diameter ansi class 125 to ansi class 5000 api 6a valves ranging from api 5000 to api 15000

Dual Flush Valve with Push Button

Get Price Quote

Fitting and Seat Covers for ceramic toilets provided by Orient Sanitary Ware comes with best valued price. Go for online purchasing of toilet seat covers with having wide range of selection available at Orient Sanitary Ware.

Non Return Valves

Get Price Quote

NON RETURN VALVES/ CHECK VALVES : WESMEC Brand Non-Return valves are equipped with a unique sealing arrangement that transmits pressure directly to the body and provides zero leakage over long life operations. Non-Return Valves are suitable for pressure up to 6000 PSI. It prevents backflow of the fluid, thereby protecting the equipment’s or instruments from getting damaged. FEATURES: • Available in a variety of end connections. • It can be easily mounted horizontally or vertically. • It is used in pump suction and discharge lines. • Hydraulic Test Pressure: up to 420 Kg/Cm². • Pneumatic Test Pressure: up to 60 Kg/Cm².> • Non Destructive Test (NDT) available on request. • Positive Material Identification Test (PMI) available on request. • Standards Followed: MSS-SP-99/ASME B16.11, B1.20.1, ISO 228, BS 4368 Part IV, BS 3799, CE Marking. • Marking and Identification of Valves as per MSS-SP-25. • Inlet arrow marked on the valve body. >APPLICATION : It is used to prevent backflow.

VIKING Alarm Check Valve

Get Price Quote

Alarm Check Valve serves as a check valve by trapping pressurized water above the clapper and preventing reverse flow from sprinkler piping. The valve is designed to initiate an alarm during a sustained flow of water (such as the flow required by an open sprinkler) by operating an optional water motor alarm and/or alarm pressure switch. These too have a universal approval from LPCB, FM Global, Underwriters Laboratories and etc. Specifications Material: Ductile Iron Pressure: 300psi End Connections: Flanged/Grooved Sizes: 200NB, 150NB, 100NB, 80NB Approvals: UL&FM

Non-Return Valves

Get Price Quote

For medium flow regulation Robust, durable versionDelivery complete with DILO connecting partsTemperature range of non-return valves -20 °C to +70 °C (media-dependent)Application range of blocking valves from -270 °C up to +400 °CAvailable in DIN 1.0460 und 1.4571 materials

Check Valves

Get Price Quote

Double Cone Valve

Get Price Quote

Double Flap valves find their application as a substitute of Rotary Airlocks i.e. to allow flow of dust and maintain airlock across the valve. It is particularly suitable for handling highly abrasive and gritty materials along with high vacuum across the valve. Two small hoppers are mounted in-line and with some space between them in an air-tight casing. Two sets of flaps/ cones seat against the discharge openings of the hoppers. The flaps or cones are held on arms that are fulcrummed on two shafts. The shafts are provided with external counter weights to counter balance the weight of flap or cone, the connecting arms and also the material pressure on top. The counter weight is so selected that the flaps / cones close tightly against the seat rings fitted at the discharge end of the hoppers to avoid leakage. The flap/ cone mounting on the connecting arms self aligning type to make the sealing airtight. For cone dump valve, the seats are sometimes provided with additional rubber rings to ensure leakproofness. The drive mechanism of these valves comprises of a geared motor with cam or linkage that alternately turns the two shafts by some degree. This results in partial lowering of the flap pair or cone at two levels alternately. Thus, as the top flap/cone lowers, material above it drops to fill the intermediate chamber. Now the top flap/cone closes and after some pause the bottom flap/cone opens to allow the material to pass out of the valve. The above mechanism ensures that any one flap/cone remains closed at any point of time thereby ensuring airlock across the valve. Applications • Steel Industry Blast Furnace, Electric Arc Furnace, BOF, etc • Fertilizer Industry Phosphate Rock Dryers & Calciners, Dryers • Non-Ferrous Copper Reverberatory Furnace, Laea Blast Furnace • Pulp & Paper Lime Kilns, Back Liquor Recovery, Bark Boilers • Sugar Industry Boiler Flue Gas, Bagging Section • Mineral Products Asphalt Stone Dryers, Cement Kilns • Pharmaceuticals Tablet Coating Fans, etc

PVC Foot Valve

Get Price Quote

With the help of our intelligent team of technicians, we render high quality services for PVCPU Belt Repairs & Joints. In a very short period of time, we have received huge appreciation for our service due to the fine finish offered to the repairs and joints. Our services are also focused at enhancing the longevity and smooth functionality of these products.

thread foot valve

Get Price Quote

Wafer Check Valves

Get Price Quote

Material :ASTM Specifications Carbon Steel,Alloy Steel,Low Temperature carbon Steel, Stainless Steel, Duplex Stainless Steel,Super Duplex Stainless Steel,any other special material.

Non-Return Valves

Get Price Quote

Simple and rugged design Pneumatic Valves these are available in sizes 1/4" to 1" BSP. They are used in applications where uni-directional flow is required.

Excess flow valves

Get Price Quote

As leading excess flow check valve manufacturers, AEPL produces several types of EFCV in various sizes and using various materials based on client needs. Screwed, flanged, internal and sandwich are the types of excess flow valves, manufactured in standard sizes by. For specific industrial processes, the valves can be completely custom-engineered. There can be modifications in the material used, pressure settings, designs and end connections.With the series 2100 valves, installation can be done on tanks or in pipelines. Our series 3100 excess flow check valves are designed for installation on tanks. Their key characteristic is high flow capacity with less pressure drop. The valves have male threads on inlet side and female threads on outlet side. These valves can beused in any position. The Anil-make series 7100 excess flow check valves come with female threads on inlet and outlet areas. These are also high flow capacity valves with low pressure drop. Designed specifically for installation in lines, these valves are ideal for liquid or vapour. The applications of flanged excess flow check valves and sandwich type valves include LPG, Propane, NH3 Storage tanks, road tanker and pipe lines. The customized valves can be used for VCM, DMA, MMA, CO2 and O2 as well. The internal excess flow check valves can be utilized for LPG Propane road tankers and storage tanks. This type is provided with arrangement for isolation and closes automatically in case of five. Our valves go through several quality checks as per industry standards. The valves are tested in high-end laboratories for performance and their ability to withstand the operating condition. Additionally, we also arrange for additional certifications as required by clients for meeting the quality standards.Sandwich type valves are fitted between to flanges of pipe joint. At AEPL, we use our experience and expertise to produce high-quality valves that can serve the client’s purpose for several years with low maintenance costs.

Swing Check Valve

12,000 Per Piece

Plastic Check Valve

Get Price Quote

Plastic Check Valve, Pp Non Return Valve, PVC Foot Valve, cpvc valve

Check Valves

Get Price Quote

Check Valves, cold rolling mills, counter balance valves, Hydraulic Pumps

Single and Double Pilot Valve

Get Price Quote

Single and Double Pilot Valve, Lever Type Hand Rotary Valve

Non Return Valve

Get Price Quote

Non Return Valve, Nozzles, solenoid relay, plastic wheel box

Check Valves

Get Price Quote

Check Valves, Ball Float Steam Trap, Thermodynamic Steam Trap

Swing Check Valves

Get Price Quote

L&T 2 Piece Design Ball Valve, AUDCO (L&T) Butterfly Valve Slim Seal

5/2 Double Pilot Valve

Get Price Quote

5 / 2 Double Pilot Valve, Flamp Proof Limit Switch Box, Vac Linear Actuator

Check Valve

Get Price Quote

Check Valve, Pipe Fitting, Actuator