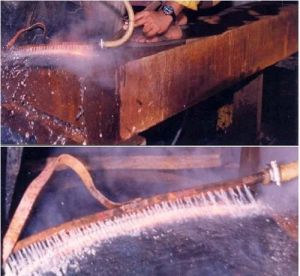

Wet Fog Dust Suppression System

1 Piece (MOQ)

Atomization is designed to reduce the surface tension of the water droplets, while increasing the number of droplets in a given area and eliminating the need for the addition of surfactants or other additives. The low level of water added through the fog/mist systems – typically at 0.01% to 0.05% by weight of the material – generally will not degrade the performance of the material. Single-Fluid Atomization This system uses an ultra-fine stream of water pumped at high pressure through single-fluid atomizing nozzles. It does not require compressed air or an additional power source other than the electricity to run its pump. Single-fluid nozzles use hydraulic atomization to generate the mist. Water is forced under pressure through a small orifice that shatters the water droplets into microscopic particles. The energy created by the high-pressure is used to atomize the water droplets, rather than increase water velocity, thereby minimizing displaced air. Features Of The Wet Fog Dust Suppression Systems: Fog systems provide highly effective dust capture combined with economical capital and operating costs. A well designed fogging system can provide excellent control of dust at the point of application without the need for chemical additives. Since fog systems only add water, they protect the integrity of the customer process. Total moisture addition to the bulk material can be realistically less than 0.1%. This makes fog suppression systems attractive in industries that cannot tolerate excess moisture, such as cement and lime production. For truly effective performance, fog dust suppression systems require tight enclosure of the transfer point that minimises turbulent, high-velocity air movement through the system. These systems consist of atomizing nozzles which produce a very fine mist droplets that float freely in the air and create fog. The spray pattern covers the particular area continuously so that the dust gets heavier and falls down.

Country of Origin : India

Material : Mild Steel

...more

Induction Melting Furnace

1 piece (MOQ)

Material : Mild Steel

Driven Type : Electric

Color : Grey

Condition : New

Power : 1-3kw

Application : Melting Furnace

Voltage : 440V

Type : Induction Melting Furnace

Country of Origin : India

...more

Induction Bearing Heater for Dismounting VEL/IBE05A

1 Piece (MOQ)

Brand Name : VEL

Condition : New

Power Source : Electric

Application : Industrial Use

Certification : ISO 9001:2008

Voltage : 440V

Type : Bearing Induction Heater

Frequency : 2 - 20 KHz

Country of Origin : India

Size : Multisizes

...more

Induction Bearing Heater for Dismounting VEL/IBE20A

1 Piece (MOQ)

Brand Name : VEL

Condition : New

Power Source : Electric

Application : Industrial Use

Voltage : 220V

Type : Bearing Induction Heater

Frequency : 2 - 20 KHz

Country of Origin : India

...more

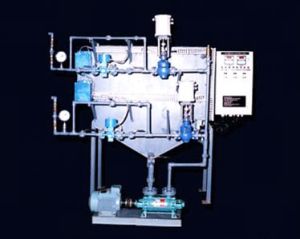

Cement Mill Water Spray System

1 Piece (MOQ)

During the process of finish grinding of clinker, lot of heat is generated inside the cement mill. The heat generated in excess has to be dissipated so that mill discharge temperature is kept at a desired level (around 90-120°C) to prevent the deterioration of the quality of cement. The increase in temperature beyond 125°C leads to dehydration of gypsum which changes the property of setting of cement. The decrease in temperature below 90°C leads to wet clogging of gypsum and the cement strength is affected. Internal water cooling in a cement mill serves to maintain the mill outlet temperature constant at preset values. VEL Cement Mill Water Spray System is the advanced method of temperature control in cement mills which results in enhanced cement quality. Application VEL Cement Mill Water Spray System comprises of complete set of pumps, valves, spray nozzles. instruments etc & all relevant accessories, assembled as one unit making it user-friendly and easy to install. Water Cooling in the Cement Mill is accomplished by injecting and evaporating water at the outlet / inlet end of the mill. The water vapour is removed from the mill together with the ventilation air, which must be so ample that the temperature does not drop below the dew point anywhere in the pipes, dedusting filter, etc after the mill. The system ensures precise control of temperature in both the chambers of cement mill by regulating the volume of injected water through motorised control valves. The design of the injection nozzles and the compressed air used for atomization gives a very good turn down ratio in the entire range of water flow regulation. When the water injection is disconnected, compressed air purging keeps the injection nozzles clean. The system may be interfaced and operated through your existing PLC/DCS or may be provided with a standalone control panel.

Driven Type : Electric

Automatic Grade : Automatic

Application : Industrial

Type : Water Spray System

Country of Origin : India

...more

Sprinkler Dust Suppression System

1 Piece (MOQ)

VEL INNOVATIVE TECHNOLOGIES PRIVATE LIMITED in joint collaboration with NODOLINI SPRINKLERS from Italy are proud to present a wide & diversified range of dust suppression systems involving high performance, heavy duty sprinklers. Vel Innovative Technologies are team of engineering experts actively involved in the design. development. manufacture and supply of various dust suppression systems including those involving heavy duty sprinklers, one among many other products, solutions, services provided to Process Industries. Nodolini are pioneers in the field of sprinkler manufacturing with over 60 years experience in the field. The sprinklers are developed through our joint effort & experience of actual client requirements. We offer total turnkey solutions for all types of open & exposed dust control situations (eg. stockpiles, haul roads. mines. open yards. thermal power plants etc). Our purpose includes design, engineering, manufacture, supply & commissioning of the system. Our goal is to provide effective solutions to the problems of fugitive dust emissions in the above mentioned areas with minimum consumption of water and electricity. The key component of these systems – sprinklers are designed to operate in adverse conditions, high pressure (15 bar), and have protected moving & exposed parts, enabling long life & trouble free performance for years of continuous service. We have developed three lines of sprinklers for our dust suppression systems: S.W. = DUST SUPPRESSION (STANDARD MODEL) WITH WATERS AND ENVIRONMENTS NOT CORROSIVE C.W. = DUST SUPPRESSION WITH CORROSIVE LIQUIDS. WASTE WATERS, SEAWATER, CORROSIVE ENVIRONMENT A.W. = DUST SUPPRESSION WITH ABRASIVE LIQUIDS (MINING), CORROSIVE LIQUIDS. WASTE WATERS, SEAWATER. CORROSIVE ENVIRONMENT Our team is always ready to evaluate and propose appropriate solutions for all type of dust suppression require-ments. Our technical staff is always available to advise appropriate models/solution based on the inputs received from our customers with respect to site conditions like quality of water, windy conditions, complicated layouts, characteristic of the dust emission, permissible dust emission levels etc.

Country of Origin : India

Material : Stainless Steel

Color : Gray

...more

Raingun Dust Suppression System

1 Piece (MOQ)

Country of Origin : India

Material : Mild Steel

Magnetic Levitation Melting

1 Piece (MOQ)

Induction levitation melting is an advanced metallurgical process that uses electromagnetic induction to suspend and heat a conductive material, typically a metal, without physical contact. This method is unique because it allows for precise control over melting and refining processes while minimizing contamination risks. Induction is preferred for levitation melting due to its efficiency, uniform heating, and suitability for handling reactive materials. Applications of induction levitation melting include producing high-purity alloys, refining exotic metals, creating specialty materials for aerospace applications, and conducting research in materials science.

Country of Origin : India

Corrosion Resistance : Yes

...more

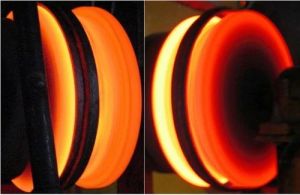

Induction Shrink Fitting System

1 Piece (MOQ)

VEL Extract Ease series, a cutting-edge solution at the forefront of technology, intelligent microcontroller based electronic control, solid state IGBT based high frequency Induction Heater, specifically designed and manufactured for dismounting and mounting of shrink fit components like bearings, inner races, coupling, pinions, gears, sleeves, throwers, retaining collar etc. Salient Features Highly efficient and fast heating compared to conventional low frequency systems. Air cooled system, so no need to handle water or any coolant Flexible air cooled coil to suit different types of job making it versatile and user friendly Compatible with rigid Induction Coils (weight less than 5 kgs) for continuous production operations. No magnetization at high frequency hence no need for demagnetization cycle. Built-in safeguards, including Over Voltage, Over Current, Coil Winding Temperature, and Device Temperature trips, etc

Automatic Grade : Semi-Automatic

Power Source : Induction

...more

Induction Plasma Heater

1 Piece (MOQ)

Plasma is a unique state of matter consisting of unbound positive and negative particles, electrically neutral overall. It lacks a defined shape unless confined. Generating plasma involves applying an electrical field to a gas, causing electrons to break free from their orbits around nuclei, creating ions and free-flowing electrons. This imparts key properties like electrical conductivity, magnetic field generation, and responsiveness to external electromagnetic fields. Sustaining plasma requires continuous energy input, making induction an ideal method for this purpose. Industrial applications of plasma include welding, metal cutting, surface treatments such as plasma spray coating, and etching in microelectronics.

Power Source : Electric

Application : Industrial Use

Country of Origin : India

Voltage : 460V

Frequency : 0.5KHz To 10KHz

...more

Induction Melting Furnace Equipment

1 piece (MOQ)

VEL MeltPro series is a comprehensive range of furnaces for melting all non ferrous metals and precious metals like silver, gold etc. This melting equipment has a long life and provides an accurate temperature measurement. Features: Power regulation (10 – 100%) Advanced software driven solid state converters. Temperature controller – works with a thermocouple probe or optional IR pyrometer. Fast acting electronic interlocks for safe and reliable operation. Automatic / Manual tilting control. Custom models with different capacities can be designed. Techincal Specification: VEL MeltPro serries consists of ►Converter ► Inverter ► Control, Protection & Interlocks► Output Transformer ►Coil / Furnace► Water Cooling & Circulating System.

Material : Mild Steel

Driven Type : Electric

Automatic Grade : Automatic

Application : Melting Furnace

Country of Origin : India

...more

Induction Heater For Pre And Post Weld Heat Treatment

1 Piece (MOQ)

The VEL PH/PW series provides a highly versatile tool for preheating, stress relieving, hydrogen bake out and post weld heat treat in a variety of pipe diameters and flat plate. Features: Designed for continuous heating operation Equipped with rugged heavy duty components to tolerate harsh working conditions Very Compact and portable (could be easily mounted on any trailer / trolley & moved by forklift / crane) All safety trips / interlocks incorporated including sensing the temperature of critical power components of the equipment Efficiency of the power source is better than 95% Low Voltage design makes it very safe to use at site Inductors are specifically designed keeping in mind ease of operation required. Thermal Profile Controller, Data Logger & Paper Chart Temperature Recorder is integrated as required. Provides uniform rapid heating in plate and pipe applications Reduces set-up time and time -to temperature

Automatic Grade : Automatic

Material : Mild Steel

Application : Pre-Heating & Post Weld Heat Treatment

...more

Induction Heat-Exchanger Tube Detacher

1 Piece (MOQ)

The roll joints on the tube sheet of shell and tube heat exchangers, formed using an expander tool, play a critical role in efficient heat transfer. We have pioneered and successfully implemented an innovative Induction shock heating process specifically tailored for this application in nuclear reactors, a feat unmatched by others. This groundbreaking technology holds potential for detaching tubes in boilers, power plants, steam generators, and various industrial systems, offering unparalleled efficiency and reliability in maintenance operations.

Shape : Round

Application : Industrial Use

Feature : Durable, Optimum Quality, Rust Proof, Supreme Finish

Type : Sheet Tube

Country of Origin : India

Finshing : Polished

...more

induction hardening system

1 Piece (MOQ)

The VEL HardTech series represents cutting-edge induction hardening, annealing, and tempering systems tailored to meet the evolving needs of the heat treatment industry. We offer complete turnkey solutions that include an advanced Induction Power Source, CNC/PLC control automation, high-frequency transformer, and custom-designed coils tailored for specific jobs. Our solutions also feature job-specific scanning (horizontal or vertical), single-shot fixtures, and rotary or indexing tables. They seamlessly integrate with semi or fully automated job loading and unloading facilities, ensuring that the system fulfils your hardening requirements effectively. Features: Manual and automated program settings with multiple pre-programmed recipes. Intuitive touch panel interface with comprehensive process monitoring features. Quick connect coil system facilitates easy replacement of induction coils. Efficient load/unload and part centering system for manual or automated operations. Designed for in-line integration, ensuring short lead times and seamless workflow. Reliable mechanical solutions ensure high system availability and productivity. Precise process control leads to excellent results and increased productivity. Energy-efficient power supply unit (>95% efficiency) reduces energy costs. Flexible design accommodates a wide range of part sizes for versatility. Modular unit for easy servicing and maintenance, minimizing downtime. Technical specification: The Induction Hardening System (VEL/IH Series) is specially designed for Induction Hardening of components on turnkey basis complete with > Induction Power Source > CNC/PLC based servo motor driven Vertical/Horizontal Scanner > Water circulating & Cooling system and Quenching system > Semi-Automated/ Fully Automated job loading/unloading facility (optional)

Country of Origin : India

...more

Induction Forging Machine

1 Piece (MOQ)

Induction forging process is energy efficient, rapid / instant heating process as it provides superior productivity, consistent quality, flexibility and reliability. VEL ForgeTech series is specially designed and manufactured for heating metal in forging, rolling, stamping extrusion, upsetting and other forming applications to obtain desired shape in Presses, Bending Machines, Forming machines, etc on turnkey basis. They are designed to heat any dimension of billets, bars, blocks, slabs etc in full or partially in materials as diverse as Steel, Stainless Steel, Brass, Bronze, Aluminium, Copper, Titanium, Silver, etc and their alloys INDUCTION HEATING POWER SOURCE Induction Heater , Thyristor / IGBT based, of varying power capacities ranging from 400 kW to 1600 kW consisting of Inverter modules auto tuned to Resonant Frequency ranging from 1 to 20kHz, incorporating Microcontroller (µC) based electronic controls, Protection/Trip circuits, Interlocks etc, Output Matching Transformer, Inductor Assemblies etc. CONTROL AND FEEDBACK SYSTEM PLC based control system & SCADA for automated system & process. All alarms generated and machine / process parameters displayed / controlled from HMI on Control Panel / SCADA. Non-contact pyrometers are used to measure the part temperature to achieve precision temperature control, to maintain temperature consistency, feedback for hold modes, option to reject job for over/under job temperatures etc. HEATING STATION The induction coil is completely contained within the steel shell and is isolated from the job with a refractory coating. There is no chance of hot slag or other materials from the furnace contaminating the room. LOADING/ UNLOADING & FEEDING SYSTEM Semi-Automated/ Fully Automated job loading/unloading facility are available, such as Vibratory, magazine, step, or bowl feeders, V-flight and other conveyor feeders to move billets into drive position, Pneumatic or hydraulic horizontal pusher, tractor drive, pinch roller drive or walking beam arrangement for moving job through the inductor, High-speed conveyors to rapidly deliver the hot job to press operator or robot pick up point, etc

Country of Origin : India

Application : Industrial

Automation Grade : Automatic

...more

Induction Brazing System

1 piece (MOQ)

VEL i-Braze Series VEL i-Braze series comprises of state-of-the-art induction brazing systems designed to meet the evolving demands in the field of metal joining. It includes an advanced light weight and portable high frequency transformer and joint specific custom designed coils together known as brazing tong. The coils can be easily fitted on and removed from the transformer. The brazing tong can seamlessly integrate with robotic arms or any automation as per client’s requirements Standard Features Application based customization Wide range of output power ratings and frequencies range Tolerates abrupt discontinuities in the coil circuit (e.g., sudden insertion, removal, or geometric changes of the workpiece). Withstands severe disturbances on incoming power lines. Integrates safety-oriented design features to prevent electric shock hazards associated with the brazing tong during operation. Features an automatic machine trip mechanism in the event of accidental contact between the brazing tong and the workpiece, ensuring the integrity of both the machine and workpiece. Safety Interlocks for Water pressure, temperature, flow, etc. Power Factor > 0.90 Output regulation> 90% Intuitive user interface Simple and effective indications TECHNICAL SPECIFICATION VEL i-Braze System (Type VEL/BR/#) consists of ► Converter ► Inverter ► Microcontroller based Control, Protection & Interlocks ► Output Transformer & Inductor ► Water Cooling & Circulating System (Optional) ► Holding Fixture (Optional) ► XYZ Slide for the Brazing Tong Assembly (Optional)

Country of Origin : India

...more

induction bearing heater

1 Piece (MOQ)

We are offering a comprehensive range of Microcontroller based Electronic Control, Induction Heater (VEL/BH series) specifically designed and manufactured for mounting of shrink fitting components such as Bearings, inner races, gears, pinons, couplings, etc.

Application : Industrial Use

Type : Bearing Induction Heater

Country of Origin : India

...more

Induction Bearing Heater for Dismounting VEL/IBE40A

1 Piece (MOQ)

Power Source : Electric

Application : Industrial Use

Voltage : 440V

Type : Bearing Induction Heater

Frequency : 2 - 20 KHz

Country of Origin : India

...more

Grate Cooler Water Spray System

1 Piece (MOQ)

VEL Cooler water spray system comprises of complete set of skid mounted pumping & valve train system along with spray nozzles & relevant accessories. All necessary instruments, control valves etc are provided. All closed loop controls, sequence of operation, alarms & Safety interlocks are provided. The system may be interfaced to your existing PLC/DCS or may be provided with a standalone control panel. DESIGN CRITERIA The purpose or application, dimensions of the Grate Cooler, the height of the clinker bed, the overall gas flow, the gas temperature, the clinker temperature profile, number of nozzles needed and the height at which the lances are to fixed in the cooler compartment, the degree of cooling required put together determines the type of is spray system to be used,that is: Compressed air atomized water spray system Spillback water spray system Fogjet / Multicone water spray system Flatjet water spray system Application In Cement Industries, VEL Grate Cooler Water Spray System is used for cooling the vent gas for any of these purposes: To increase the efficiency of ESP by reducing fugitive dust emission. To reduce the power consumption of the vent outlet fan. To maintain a slightly more negative pressure at vent outlet thus contributing in reducing fugitive emission. To reduce the temperature so that the upstream conveying equipments could be designed for lower temperatures thus reducing the capital cost. To cool the clinker directly so that the inlet temperature to cement mill is within controllable limits. To control the depth of the clinker bed both to avoid grate burn-out due to low bed depth, and to avoid stalling the cooler fans due to excessive bed depth. To limit fluctuations in the secondary air temperature as this can upset the kiln temperature profile and adversely affect clinker quality. Principle Of Operation In VEL Grate Cooler Water Spray System, the temperature of the stream of gas / clinker is cooled in three stages: Heating of the injected liquid to the boiling point temperature corresponding to the system pressure. Conversion of part of the liquid into a gaseous state by evaporation of the liquid. Superheating of the evaporated liquid. We can also provide Grate Cooler Water Spray System especially for Direct Cooling of Clinker bed. This is normally required when the cooler is operated above its designed capacity. We design, manufacture, supply to achieve your ultimate goal.

Driven Type : Electric

Condition : New

Automatic Grade : Automatic

Application : Industrial

Type : Water Spray System

Weight : 200-300kg

Country of Origin : India

...more

Fog Cannon Dust Suppression System

1 Piece (MOQ)

When vast open spaces require dust suppression and a semi permanent system is not a practical option, the solution may lie with the introduction of a fog cannon to the site. These huge mobile and expensive units can utilise up to 60 hydraulic spray nozzles mounted circumferentially around the outlet head of a large fan assisted barrel. The concentration of nozzle spray together with the high flow of air from the fan, throws the droplets many metres towards the source of the dust activity. The droplets scatter in a plume of relatively soft spray and can capture fugitive dust before it becomes airborne and a major problem.

Country of Origin : India

...more

Wheels Induction Hardening Service

Wheels induction hardening service utilizes electromagnetic induction to heat the surface of wheels, followed by rapid quenching for enhanced properties. This process strengthens the wheels, improving wear resistance and durability, crucial in automotive, railway, and heavy machinery sectors. Selective hardening preserves core toughness and structural integrity. The service significantly enhances wheel performance and longevity, ensuring reliable operation under heavy loads and harsh conditions. It's essential for safety, efficiency, and reducing maintenance costs in various transportation and industrial applications.

...more

Sprockets Induction Hardening Service

Sprockets induction hardening service utilizes electromagnetic induction to heat the surface of sprockets, followed by rapid quenching for enhanced properties. This process strengthens the sprockets, improving wear resistance and durability, crucial in automotive, machinery, and industrial sectors. Selective hardening preserves core toughness and structural integrity. The service significantly enhances sprocket performance and lifespan, ensuring reliable operation under heavy loads and harsh conditions. It's essential for maintaining efficiency, reducing maintenance costs, and ensuring safety in various drive systems and machinery applications.

...more

Smaller Diameter Induction Hardening Roll Service

Smaller diameter induction hardening roll service utilizes electromagnetic induction to heat the surface of smaller diameter rolls, followed by rapid quenching to enhance their properties. This process strengthens the rolls, increasing wear resistance and durability, particularly crucial for precision machining and manufacturing applications. By selectively hardening the surface, the rolls maintain their core toughness and dimensional stability. This service significantly improves the performance and lifespan of smaller diameter rolls, ensuring reliable operation in various industries such as automotive, aerospace, and electronics.

...more

Shaft Induction Hardening Service

Shaft induction hardening service involves heating the surface of a shaft through electromagnetic induction, followed by rapid quenching to create a hardened layer. This process enhances the shaft's durability, wear resistance, and strength, particularly in high-stress applications such as automotive components, machinery, and industrial equipment. By selectively hardening only the surface, the core remains relatively unaffected, retaining its toughness. This service is crucial for improving the performance and longevity of shafts subjected to heavy loads and harsh environments.

...more

Pinion Induction Hardening Service

Pinion induction hardening service employs electromagnetic induction to heat the surface of pinions, followed by rapid quenching for enhanced properties. This process strengthens the pinions, increasing wear resistance and durability, crucial in automotive, aerospace, and machinery sectors. Selective hardening preserves core toughness and structural integrity. The service significantly improves pinion performance and lifespan, ensuring reliable operation under heavy loads and harsh conditions. It's essential for safety, efficiency, and reducing maintenance costs in various industrial applications.

...more

Pin Induction Hardening Services

Pin induction hardening services utilize electromagnetic induction to heat the surface of pins, followed by rapid quenching for enhanced properties. This process strengthens the pins, increasing wear resistance and durability, vital in automotive, aerospace, and machinery sectors. Selective hardening preserves core toughness and structural integrity. The service significantly improves pin performance and lifespan, ensuring reliable operation under heavy loads and harsh conditions. It's essential for safety, efficiency, and reducing maintenance costs in various industrial applications.

...more

Large Diameter Induction Hardening Rolls Service

Large diameter induction hardening rolls service employs electromagnetic induction to heat the surface of rolls with substantial diameters, followed by rapid quenching to enhance their properties. This process strengthens the rolls, increasing wear resistance and durability, particularly vital for heavy-duty applications in steel, automotive, and manufacturing industries. By selectively hardening the surface, the rolls maintain their core toughness and structural integrity. This service significantly improves the performance and longevity of large diameter rolls subjected to high loads and extreme conditions.

...more

Induction Stress Relieving Services

Unlock the power of relaxation and durability with our induction stress relieving services. Using advanced technology, we alleviate internal stresses in metal components, enhancing their stability and longevity. Whether it's weldments, castings, or machined parts, our precise process ensures uniform heating and controlled cooling, resulting in improved performance and reduced risk of deformation. With our expertise and state-of-the-art equipment, we deliver fast and reliable stress relieving solutions tailored to your needs. Experience superior quality and durability with our induction stress relieving services today.

...more

induction shrink fitting service

Induction Shrink Fitting Services Trouble Disassembling Components? Let Our Expertise Solve It for You. What is Induction Shrink Fitting? Induction shrink fitting is a specialized process used to assemble or disassemble components by utilizing the principle of thermal expansion and contraction. In this process, induction heating is employed to heat one component (usually the outer component or the housing) to a specific temperature, causing it to expand. Once the desired temperature is reached, the inner component (typically a shaft or a smaller part) is inserted or removed while the outer component is still hot. This method is commonly used in various industries such as automotive, aerospace, manufacturing, and machinery for assembling gears, bearings, pulleys, shafts, and other components that require a precise and strong fit. Services we provide: Induction Shrink Fitting of: Roller Bearing Inner Race Bush Sleeve Pinions Rotor Shaft Assemblies Turbine blades Pressure Tube in PHWR

...more

Induction Heater for Pre and Post Weld Heat Treatment Service

An induction heater for pre and post-weld heat treatment service utilizes electromagnetic induction to heat metal components uniformly. In pre-weld treatment, it aids in stress relief, reducing cracking risks, and enhancing weld quality. Post-weld, it ensures uniform heating for tempering, annealing, or stress relieving, improving material properties and weld integrity. This efficient heating method minimizes distortion and improves productivity, offering a reliable solution for industrial welding operations requiring precise heat treatment.

...more

induction hardening service

Induction hardening service enhances the surface properties of metal components by rapidly heating them with electromagnetic induction, followed by quenching. This process strengthens the surface, improving wear resistance and durability, crucial in automotive, aerospace, and manufacturing industries. Selective heating ensures only targeted areas undergo hardening, preserving the component's core properties. The service significantly enhances component performance and longevity, ensuring reliable operation under demanding conditions. It's an essential process for optimizing the durability and efficiency of various mechanical parts and systems.

...more

induction brazing services

Ensure Consistency Every Time with our Induction Brazing Services. What is Induction Brazing? Induction brazing is a joining process that uses electromagnetic induction to heat and melt a filler material (brazing alloy) without directly melting the base metals being joined. This method is commonly used to create strong and durable joints between two or more metal components. Here's how the induction brazing process typically works: Preparation: The metal parts to be joined are thoroughly cleaned and prepared to ensure proper bonding. Brazing Filler Material: A brazing filler material, often in the form of a pre-placed paste, powder, or wire, is applied at the joint area between the metal parts. Induction Heating: An induction coil is placed near the joint area, and an alternating current passes through the coil, creating a rapidly changing magnetic field. This magnetic field induces eddy currents within the metal parts, generating heat due to resistance. The heat is concentrated at the joint area, where the brazing filler material is located. Brazing Temperature: The induction heating raises the temperature of the joint and the brazing filler material to the brazing temperature, typically above the melting point of the filler material but below the melting point of the base metals. Capillary Action: As the brazing filler material melts, it wets the surfaces of the base metals and is drawn into the joint by capillary action. Cooling and Solidification: Once the brazing process is complete, the joint is allowed to cool and the brazing filler material solidifies, forming a strong and durable bond between the metal parts. Induction brazing offers several advantages: Precision Heating: Induction heating allows for precise and localized heating of the joint area, minimizing heat-affected zones in the surrounding areas. Fast and Efficient: The induction heating process is fast, efficient, and energy-saving compared to other heating methods like flame brazing. Clean and Controllable: Induction brazing produces clean and controlled joints without the need for flux, reducing post-processing requirements. Versatility: It can be used for joining a wide range of metals and alloys, making it suitable for various applications across industries such as automotive, aerospace, electronics, and manufacturing. Quality Joints: The controlled heating and precise melting of the brazing alloy result in high-quality joints with excellent strength, corrosion resistance, and structural integrity. Overall, induction brazing is a reliable and effective method for creating strong and durable joints in metal components, offering benefits in terms of precision, efficiency, cleanliness, versatility, and quality. Services we provide: Induction Brazing of: Copper parts for compressors. Copper components of transformers. Brass components. Submersible pump rotors. Ring cable lugs. Aluminium component joints. Soldering of brass components. Steel components joints. Brazing of storage water heater Elements. Diamond tipped cutting tools. Carbide tipping of cutting tools. Optical Frame Brazing. Fuel pipe Brazing. Vacuum brazing of critical components. Brazing stainless steel orthodontic parts. Brazing of stainless steel to Brass. Rocker Pins. Hydraulic Hose.

...more

Groove Rings Induction Hardening Service

Groove rings induction hardening service utilizes electromagnetic induction to heat specific sections of groove rings, followed by rapid cooling to enhance their surface properties. This process strengthens the rings, improving their wear resistance and durability, crucial in applications where heavy loads or friction are common, such as automotive transmission components and industrial machinery. By selectively hardening only the grooves, the rings maintain their core toughness. This service significantly extends the lifespan and reliability of groove rings in various mechanical systems.

...more

Gear Teeth Induction Hardening Service

Gear teeth induction hardening service employs electromagnetic induction to heat the surface of gear teeth, followed by rapid quenching for enhanced properties. This process strengthens gear teeth, increasing wear resistance and durability, crucial in automotive, aerospace, and machinery industries. Selective hardening preserves core toughness and dimensional accuracy. The service significantly improves gear performance and lifespan, ensuring reliable operation under heavy loads and harsh conditions. It's essential for maintaining efficiency, reducing downtime, and enhancing the overall reliability of gear systems.

...more

Fasteners Induction Hardening Service

Fasteners induction hardening service utilizes electromagnetic induction to heat the surface of fasteners, followed by rapid quenching for enhanced properties. This process strengthens fasteners, boosting wear resistance and durability, vital in automotive, aerospace, and manufacturing sectors. Selectively hardening the surface preserves core toughness and structural integrity. The service substantially enhances fastener performance and longevity, ensuring reliable and secure fastening solutions across diverse applications. It's a critical process for meeting stringent quality standards and maintaining safety in various industrial settings.

...more

Die Induction Hardening Service

Die induction hardening service utilizes electromagnetic induction to heat the surface of dies, followed by rapid quenching to enhance their properties. This process strengthens the dies, increasing wear resistance and durability, crucial for precision manufacturing industries like automotive, aerospace, and tooling. By selectively hardening the surface, the dies maintain their core toughness and dimensional accuracy. This service significantly improves the performance and lifespan of dies, ensuring reliable and consistent production processes, ultimately enhancing productivity and product quality.

...more

Cam Induction Hardening Service

Cam induction hardening service utilizes electromagnetic induction to heat the surface of cams, followed by rapid quenching to enhance properties. This process strengthens the cams, improving wear resistance and durability, critical in automotive, machinery, and aerospace sectors. Selective hardening preserves core toughness and structural integrity. The service significantly boosts cam performance and lifespan, ensuring reliable operation under heavy loads and harsh conditions. It's vital for maintaining efficiency, reducing downtime, and enhancing the overall reliability of cam systems in various industrial applications.

...more

Brake Drums Induction Hardening Service

Brake drums induction hardening service employs electromagnetic induction to heat the surface of brake drums, followed by rapid quenching to enhance their properties. This process strengthens the drums, increasing wear resistance and durability, crucial for automotive braking systems. By selectively hardening the surface, the drums maintain their core toughness and structural integrity. This service significantly improves the performance and lifespan of brake drums, ensuring reliable and safe braking in vehicles, contributing to overall road safety and driver confidence.

...more

Ball Bolt Induction Hardening Service

Ball bolt induction hardening service employs electromagnetic induction to heat the surface of ball bolts, followed by rapid quenching for enhanced properties. This process strengthens the bolts, increasing wear resistance and durability, crucial in automotive, aerospace, and machinery sectors. Selective hardening preserves core toughness and structural integrity. The service significantly improves ball bolt performance and lifespan, ensuring reliable operation under heavy loads and harsh conditions. It's essential for safety, efficiency, and reducing maintenance costs in various industrial applications.

...moreOpening Hours

At Vel Innovative, our organisation is locked in the manufacturing and trading of high-performing induction machines. We use our extensive experience to create flexible Solid State Inverter Induction machines for Heating, Annealing, Brazing, Hardening and various other purposes.

Our Business

With our ability, we have provided more than 500 High-Frequency Induction Heating machines, Induction Brazing machines, Induction annealing machines and so on to the national and worldwide market. Utilisation of high-innovation parts within the machines guarantees highspeed. Giving driving force to the client\'s business, our Induction machines offer maximum productivity in the least time.

Established in 1971 in Mumbai, Vel Innovative began its journey to victory by advancing handle control types of equipment. After this tremendous victory, the company startedmanufacturing different electronic supplies. Ms. Bharthi is the organisation\'s CEO, beneath whose headship we have set a solid toehold within the worldwide market.

Our Standing inthe Industry

Nowadays, we have carved a speciality as one of India\'s major Induction Brazing Machine Producers and providers. We have outlined our business approaches to offer the most significant benefit to the clients with the most minor speculation.

We enable clients by advertising the predominant induction machines at exceptionally reasonable costs. Because of our suitablebusiness approaches, we have earned honours from gigantic clientele based in India and overseas.