Vibrating Feeders

Get Price Quote

The Vibrating Feeders (Vibratory feeder), offered by us, are used to transfer the large size materials and granular materials from Silo to receiving device uniformly, periodically and continuously in the production flow and to feed materials into the crusher continuously and uniformly also to screen the materials in the sandstone production line. Our Vibrating Feeders are widely used to match the crushing and sieving equipment in many industries including metallurgy, coal mine, mineral dressing, building material, chemical, grinding, etc. Working Principle of Vibrating Feeders There are two eccentric shafts rotating at high speed at the same time from opposite directions, thus the strong centrifugal force is formed. The component forces of centrifugal force along the vibrating direction will always overlap each other, then counteract with that of vertical force from vibrating direction, then exciting force along single direction is formed to drive the feeder vibrate along straight line. When materials are fed into the feeder, they may be thrown up and move like Para curve, then fall down. The materials will move forward on the slope surface of the feeder.

Vibratory Bowl Feeder

45,000 - 85,000 Per piece

1 Piece (MOQ)

Best Deals from Vibratory Feeders

Electromagnetic Vibratory Feeder

Get Price Quote

We are offering electromagnetic vibratory feeder. " la'mina" electromagnetic vibratory feeder has been designed and manufactured for the past four decades . robust in construction , the equipment is used for feeding dosing screening of powders crystals at controlled rate from one gram per minute to 50 tons per hour . la'mina electromagnetic vibrator feeders are available on the basis of watts - 50 - 75 - 100- 200- 400 -750 watts are the fast selling models . generally these models are available ex stock . The vibrator unit can be bolted with ms - ss tray of special design as required by the customer . a separate thyristor controller is included in the supply - plastic body , ms body duly powder coated , ss pharma finish . Please let us know material handled - acidic basic quantity handled per hour , method of feeding , screen mesh desired , inlet to outlet distance - any other information you feel important to share . Supplied to pharma mineral mining chemical and other industries . Other products manufactured by us include vibrating screens , vibratory feeder , magnetic separators , conveyors and bucket elevators

Industrial Vibratory Feeder Controller

15,000 Per Piece

2 Piece(s) (MOQ)

Vibratory finishing equipment

Get Price Quote

Vibratory Finishing Machines are mass finishing machines, used for deburring, polishing, descaling, and surface improvement on metal and plastic components. Working Principle The machine has a steel bowl lined with rubber or polyurethane which is filled up with required media (either ceramic, plastic, maize etc. depending upon the finish required) and components. Eccentric weights are mounted on an extended shaft attached to a heavy duty motor to cause vibrations and create a spiral of the media and the components. Variations in vibration, achieved by varying weights and angles, and suitable combination of media enable machine to be used for different components.

Vibrating Feeder

Get Price Quote

Bevcon wayors Pvt ltd offers a full line of vibrating feeders serving to the core industry like Thermal power, Steel, mining &cement etc. Vibrating feeder is one of the preliminary types of feeding arrangements. The discharge of material is possible through induced vibrations through electrically driven unbalanced motors. It is possible to generate elliptic, circular or linear vibrations through adjustable fly weights attached to the motors. The centrifugal force generated through theses weights is adjustable and hence variation in vibrations is achieved. Accurate discharge control achieved through the adjustment of centrifugal forces.

Vibrating Feeder

Get Price Quote

Features Stable performance &Reliable operation. Easy to adjust &Easy to maintain Long span life &No pollution with closed body Good performance-conditioning, it can be used in any severe environments Description Vibrating Feeder is a kind of linear-direction feeding equipment, in the mineral ore &rocks processing plants, it can send materials to crusher evenly and continuously. At the same time, it can screen materials roughly, increasing the practical handling capacity of the whole production line. Application SBM heavy-duty feeders have good performance in the mining, construction, road building, bridge construction, and quarrying, recycling, aggregates and cement industries. Almost all kinds of minerals &rocks and some other materials processing plants can use the vibrating feeder.

Vibratory Feeder

Get Price Quote

This comprises of horizontal tray mounted fibre glass strips to ensure flexible linear motion. The vibration to the tray is given by an electromagnetic coil mounted below it. Due to the high frequency linear vibration of the tray, material gradually moves the material from the hopper into the tray and discharges at the other end.

Vibrating Feeders

Get Price Quote

Syntron® vibrating feeders for heavy industries are distributed by Dph Engineering under licence. These feeders are ideal for supplying a variety of bulk materials from silos, hoppers, bins, and storage piles.

Vibrator Feeder Controller

3,550 Per Piece

Vibrating Feeder

Get Price Quote

We have a unique range of Screw Feeders which is highly supreme in its quality. Our range encompasses of twin screw feeders, typical screw feeders etc of premium quality. We have also gained the position of a renowned typical screw feeders manufacturer and exporter from India.

Electromagnetic Vibrating Feeder

Get Price Quote

Mitool Make Vibrating feeders are most efficient & economical to convey the bulk materials & in the simplest easiest means of controlling the flow rate.The Vibrating feeders are extensively used in mines, chemicals, ceramic, Rubber, Pharmaceuticals, clay, Iron & steel Industries, collieries, Quarries of glass industries for handling of all type of materials capacities from 1 Ton to 400 Tones per hour.Vibrating Feeders are operated by giving pulsating D.C. supply. When this pulsating supply passed through starter creates a series of interrupted pulls on the Armature. 3000 pulse (Vibration) are occurring in one minute. The Vibrating feeder consists of vibrating trough fitted to the drive unit of considerable weightsThe electromagnet unit is mounted inside a heavy housing unit, The power unit which is mounted inside the housing houses the spring bars (Flats) which consisting of a number of leaf springs clamped at the two ends of the power unit.A heavy fabricated centre piece carries the magnet armature at one end & vib feeder trough at other end. The centre clamp tightens at the middle of the spring bar system .Stiffeners & gussets are provided to make the trough rigid. Our Feeders Protects the belt conveyors from damage by feeding the material on to the belt conveyors from storage hoppers, silos, surge hoppers & dumpers at the controlled rate. In magnetic feeders there are no wearing mechanical parts, such as gears, cams, belt, bearing, eccentrics weights or motors.Mitool Vibratory feeders are most economical equipments.

Vibrating Feeder

Get Price Quote

Features of Vibrating Feeder Stable performance &Reliable operation. Easy to adjust &Easy to maintain Long span life &No pollution with closed body Good performance-conditioning, it can be used in any severe environments

Vibratory Linear Feeder

Get Price Quote

The electromagnetic vibratory feeder consists of a tray made of mild steel and a body housing the electromagnet. The tray which is connected to the armature of the magnet vibrates as the magnet gets energised. The vibration sets the material in motion. Controlling of vibration gives the controlled flow of the material. The body housing the electromagnet is made in totally enclosed design to prevent dusting. Useful to any continuous process industry where automatic controlled flow of material is required. The electromagnetic vibratory feeder consists of a tray made out of mild steel or stainless steel and a body housing the electromagnet. The tray which is connected to the armature of the magnet vibrates, as the magnet gets energized. The vibration sets the material in motion. Controlling of vibration gives the controlled flow of the material. The body housing the electromagnet is made in totally enclosed design to prevent dust going inside.

Vibratory Feeder

Get Price Quote

Vibratory Feeders are ideally suited for controlling the flow of bulk material. Vibrations produced are smooth, uniform, volumetric flow that is fully controlled from coarse to fine. Vibratory feeders are used to control product flow in bulk handling operation such as packaging, batching, mixing, drying, weighing, sprinkling and spreading. We provide Electromagnetic type and Unbalanced Motor vibratory feeders. For vibration control we use Electronic Vibrator card with coarse & fine potentiometer.

Vibratory Feeder

Get Price Quote

Electro magnetic vibratory feeders are capable of conveying bulk material from storage to processing or between processes at continuous controlled rate of flow. It enhances the bulk handling productivity, equipped with a highly reliable electro magnet which produces vibrations for step less conveyance of materials. ss construction for feed pan and hopper bigger hopper gentle but fast vibration micro controller based with digital frequency and on off con.

Vibratory Feeder

Get Price Quote

Loss-In-Weight Feeder

Get Price Quote

Loss-In-Weight Feeder

Get Price Quote

Electro Magnetic Vibrating Feeder

Get Price Quote

Electromagnetic vibrating feeders are equipped with electromagnetic drives which generate vibrations required for conveying of material. The electromagnetic drives are robust in construction with very high reliability factor. These conveyors come with a specially manufactured controller required for operation of the electromagnetic conveyor. These controllers convert the input AC supply voltage into pulsating DC output which results in generation of vibrations. A thyristor such as a silicon controlled rectifier is used for this purpose. The fringe angle of the SCR can be varied sleeplessly using a potentiometer or an analogous electrical signal / PLC signal from an external command variable unit, which in turn increases / decreases the amplitude of vibrations thereby controlling the output of the conveyor as required. As in the case of electromechanical feeders depending on the material conveyed, the conveyors can be supplied on two types viz, through type and tubular type. Suitable liners in case of through conveyors are provided where severely abrasive materials are handled as in the case of electromechanical conveyors. ADVANTAGES Easy & stepless variation of delivery of material either manually or automatically possible. Delivery remains generally constant in spite of fluctuations in supply voltage ( + 10% for voltage variation & + 3% for frequency variation.) Drive is extremely robust and simple in construction. Electromagnetic drive is dustproof and is impervious to moisture

Vibrating Feeder

Get Price Quote

Technical features and advantages Stable performance &Reliable operation. Easy to adjust &Easy to maintain Long span life &No pollution with closed body Good performance-conditioning, it can be used in any severe environments

Electro Magnetic Vibrating Feeders

Get Price Quote

Electromagnetic vibrating feeders are equipped with electromagnetic drives which generate vibrations required for conveying of material. The electromagnetic drives are robust in construction with very high reliability factor. These conveyors come with a specially manufactured controller required for operation of the electromagnetic conveyor. These controllers convert the input AC supply voltage into pulsating DC output which results in generation of vibrations. A thyristor such as a silicon controlled rectifier is used for this purpose. The fringe angle of the SCR can be varied sleeplessly using a potentiometer or an analogous electrical signal / PLC signal from an external command variable unit, which in turn increases / decreases the amplitude of vibrations thereby controlling the output of the conveyor as required. As in the case of electromechanical feeders depending on the material conveyed, the conveyors can be supplied on two types viz, through type and tubular type. Suitable liners in case of through conveyors are provided where severely abrasive materials are handled as in the case of electromechanical conveyors.

Loss-In-Weight Feeder

Get Price Quote

Vibratory Feeder

Get Price Quote

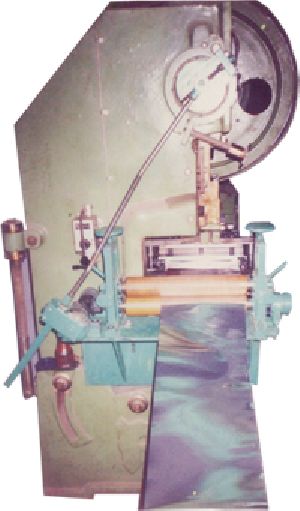

Mechanical Roll Feeder

Get Price Quote

Known to have unmatched quality, our mechanical roll feeder for power presses are available in the range of 2 roll feeder. These are designed to provide maximum possible output in the smallest time frame. To ensure their long service life, the feeders incorporate wear resistant roller. The product also has small turning inertial which enables fast stopping at any stage further ensuring feed precision. Main application area of our quality mechanical roll feeder for power presses are rolling metals coils, Aluminium and Brass.

Linear Vibratory feeder

Get Price Quote

The linear vibratory feeders are the natural extension of Bowl feeders and are required to be used when the parts are to be carried over a long distance from the Bowl feeder. Key Benefits Sturdy and robust design! Epoxy Encapsulated Magnet coils for lasting life! Alternating current Multi magnet system for uniformly distributed vibrations! Electronic solid state controller for adjusting feed rate!

Vibrating Grizzly Feeder

Get Price Quote

Nawa Engineers models with 800 mm, 1000 mm, 1200 mm, 1350 mm and 1500 mm width and different lengths to suit, Capacity range: 50-750 TPH.

Volumetric Vibratory Feeder

45,000 Per unit

Grizzly Feeder

Get Price Quote

Being reputed vibrating grizzly feeder manufacturers in India our Grizzly Feeder is able to withstand extreme shock loads. They are basically conveying deck with pan and grizzly combination, back and side renewable liners. Grizzly Feeder is non-plugging and stepped grizzly, separately renewable, for material tilting and easy fines passing. As leading Vibrating grizzly feeder manufacturers in India we have installed Vibrating unit consists of two contra-rotating eccentric shafts, geared together in oil-bath. Setting of amplitude is affected at still machine by varying unbalance. Actuation is by 4-pole motor and V-belts drive. Special steel springs are arranged for the installation on concrete or steel supporting structure.

Vibrating Feeder

Get Price Quote

Vibrating feeder is one key machine used for conveying the raw material whose size is the cube to the feed inlet with the smooth speed.Feeder machine applied in the sand production line and stone production line can feed the raw material for the crushing machine and sand maker, which can be widely applied in the industries such as the sandstone producing, ore dressing, building material and the chemical industry. Vibrating grizzly feeder can produce the centrifugal force by the eccentric rotor, which can make the sieve compartment to be one circle movement and the material can be conveyed to the feed inlet with the movement of the vibration of the sieve compartment. This product has the advantages such as simple structure, easy operation, low energy consumption, good continuity, low noise and credible operation, and its feeding capacity can be adjusted according to the practical demand of the clients. CME Mining Machinery is one major feeder manufacturer, which has the big producing capacity and the perfect sale service, and which has become the leader in the same field of china vibrating feeder, and the element above on can be useful to boost the promotion of mining machine all over the world.