ar brick lining

Our range of Epoxy & Polyurethane compounds for flooring and wall coating consists of the following : A. Epoxy P.U. Primer : This is a two component system recommended as base coat for all coatings, screed lining and self levelling systems. B. Epoxy Screed Mortar : This is a three component solvent free systems which is to be mixed at site and trowelled to thickness of 3mm, 5mm and 10mm depending upon site requirements considering the chemical conditions, load strength, etc. This is highly chemical resistant and imparts good mechanical strength. This system is recommended for warehouses, loading ramps, acid alkalis tank pads, D.M. Plants, ETP, etc.

...more

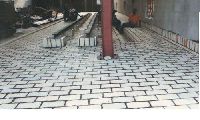

Acid Proof Brick Lining

VIKOPROOF CORROSION RESISTANT CEMENTS AND INTERLINERS VIKOPROOF Acid proof Cements are special products for acid resistant construction. They have been developed to their present pitch of perfection since 1972. Their judicious use makes it possible to resist attack by chemicals under almost all conditions met with in practice: These special cements have been in use since 1972 in many industries viz. Petrochemicals, Dyes and Dye Intermediates, Paper, Steel, Fertilizers, Power etc. for their process plants, ETP, D. M. Plants, Water Treatment Plants, Pickling Line, etc. A brief summary of various VIKOPROOF acid alkali proof cements, Membranes, Monolithic Lining and Coatings are detailed below: A. WATER GLASS SILICATE CEMENTS (IS 4832 PART I) 1. VIKOPROOF - SD Sodium Silicate Cement VIKOPROOF - SD is a two part mortar, consisting of a powder filler and a liquid binder. The cement powder is to be mixed with a special sodium waterglass solution. The Cement mortar is suitable to resistance against hydrochloric acid, nitric acid, sulphuric acid, halogen compounds, except fluorine, particularly at elevated temperatures.

...more

Acid Proof Bricks

We are offering acid proof materials, acid proof bricks. We introduce ourselves as one of the leading manufacturers of acidalkali proof cements and allied products since the last four decades. our corrosion resistant cements under the brand name “vikoproof” are manufactured and marketed conforming to strict quality control and specifications as required by our valued customers. apart from manufacturing, we are also one of the leading applicators for carrying out the following lining jobs 1) acidalkali proof tilebrick lining(using conventional tiles) and also using branded tiles like endura, pelican, etc 2) epoxy coatings in tanks, shop floor walls, tank linings, etc. epoxy coatings and glass flake filled epoxyvinyl ester coatings in dmwt, etc 3) epoxy screed lining of varying thickness in dm plant tanks, acidalkali storage areas, etp tanks, process floor, water treatment plants, etc 4) epoxy self level flooring(slf) in pharmaceutical, power, automobile, textiles industries for seamless and aesthetic floorings with colour shades of choice 5) pu coatings –water based and solvent based, for wall coating pu screed lining and epoxy pu self levelled floorings 6) ppgl linings in chemical storage areas, tanks, etc

...more

rust removers.

Be first to Rate

Rate ThisOpening Hours