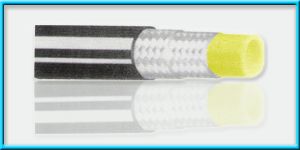

Thermoplastic Hose

Reinforcement : 1/2 Braids high tensile synthetic fiber wire.

Super Rock Drill Hose

Application Heavy duty services for air drills especially in mines, quarries and general construction work. - Natural and synthetic rubber tube. - Textile reinforcement. - Abrasion, weather and heat resistant cover.

...more

STANDARD DUTY NON-TOXIN DELIVERY HOSE

Construction : - Strong flexible and smooth non-toxic plasticized PVC . - Stock resistant PVC spiral. - Crushing, abrasion and weather resistant, light corrugated outside.

...more

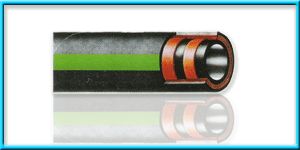

ROCK DRILL HOSE WIRE BRAIDED

Application For uses in mines where very high pressure is required. - Oil resistant synthetic nitrile rubber tube. - High tensile steel wire reinforcement. - Abrasion, weather and heat resistant cover.

...more

Rock Drill Hose

Application For the most severe conditions in open cast mines & quarries - Natural and synthetic rubber tube. - Textile reinforcement. - Abrasion, weather and heat resistant cover.

...more

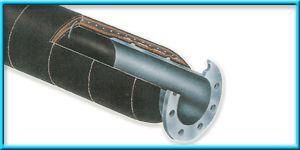

ROAD & RAIL TANKER HOSE

End connections Normally flanged type or threaded nipple i .e. built in type / vulcanize / crimped / swaged in hose. Couplings As per BS 2464 or Lug type or Camlock type. Male or female or both end male or female as per requirement of purchaser. Application Discharging of petrol and diesel oil from tank truck & between tank, & trucks & trailers, suitable for pressure, vacuum and self discharge . Very low deformation where used for petrol.

...more

QUICK RELEASE COUPLINGS (QRC)

Type 1) Double Check Valve QRC i,e. with self Sealing Valve at coupler & adaptor ends. 2) Single Check valve QRC i,e. self sealing valve at coupler & through types adaptor. 3) Without Check Valve QRC i,e. both coupler & adaptor through type. Application Wide application on fluids line connections like air, steam, gases, liquids, oil, etc, used in FERTILIZER, CHEMICAL PETROLEUM, FURNACES,TEXTILE MACHINE, MACHIN TOOLS, REFRIGERATIONS & MANY MORE INDUSTRIES. The advantages of Quick Release Couplings: 1. Instant connection or disconnection without a drop leakage due to internal action of valves.2. Suitable technology.3. High mechanical precision.4. A quality of materials and sealing suitable for every fluid.5. A rigorous control which ensures safety for use with gas, oxygen, hydrogen, propane, steam, solvent & acids acetylene etc.

Size : 1/8" upto 3"

...more

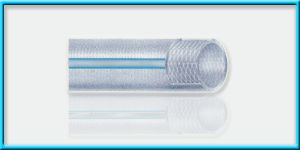

PVC BRAIDED HOSE (TRANSPARENT)

Application Transparent hose for a wide of applications like air, irrigation and general purpose. Construction - Transparent plasticized PVC tube. - High tensile synthetic textile reinforcement. - Abrasion, ozone and weather resistant

...more

power hose

Construction : - Special PVC compound resistant tube to pesticides and fertilizers. - High tensile synthetic textile reinforcement - Abrasion, ozone and weather resistant special PVC compound cover.

...more

Pneumatic Hose

Application For general construction work, road building, tunneling, mining ; for pneumatictools in industries; for type inflation in service stations. - Special synthetic rubber tube. - Textile reinforcement. - Abrasion, weather and heat resistant cover.

...more

PHOSPHORIC ACID SUCTION

Application: These hoses are very flexible allowing full flow and pipe line made with abrasion & acid resistant available with or without wire reinforcement. Wire reinforcement type has coil of steel wire buried in hose to keep it from collapsing under full suction. Used in both suction & discharge hose. Flanged ends are drilled to bolt to companion flanges using standard flat faced flanges. They provide a tight seal without a gasket since the flanges rotate freely. Alignment of bolt holes is easy, reducing installation time to a minimum.

Temperature : 150°C

...more

Oil Suction & Discharge Hose

Reinforcement : Multiple plies of textile fabric with GI embedded wire.

Oil Hose

Construction : - Strong flexible and smooth oile resistant PVC/nitrile compound ( super elastic type for low temperatures upon request) - Shock resistant PVC spiral. - Crushing, chemical agents, abrasion and weather resistant, light corrugated outside.

...more

NON-TOXIN WINE HOSE

Construction : - Strong flexible and smooth non-toxic plasticized PVC. - Shock resistant PVC spiral. - Crushing, abrasion and weather resistant, light corrugated outside.

...more

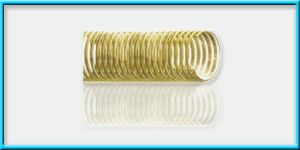

NON-TOXIN DELIVERY STEEL SPIRAL HOSE (TRANSPARENT)

Construction : - Strong flexible and smooth non-toxic plasticized PVC. - Stock resistant galvanized spiral. - Crushing, abrasion and weather resistant, smooth outside. Application For suction and delivery of water, mineral water, fruit juices, liquids etc in shipyards, industries, buildings, agricultural and industrial Machineries.

...more

MULTIOIL SUCTION & DISCHARGE

STANDARD DUTY-GPG Standard Duty Oil Suction and Discharge Composite hoses are designed for handling wide range of fuel, lubricant where light weight and high flexibility is required. APPLICATION COMPOHOSE™ hoses and hose assemblies are recommended for Rail Tank Wagons, Tank Truck Loading and Unloading, Storage tanks transfers and other standard duty applications COMPLIANCE Standard Duty Multi oil suction and discharge composite hoses and manufactured in accordance to EN 13765 / 2010 Type 2. PRODUCT HANDLE Gasoline, high speed diesel, paraffin, kerosene, lubricating oil and 100% aromatics as well as black oils and heavy lubricants and solvents. FEATURES 1. Complete product compatibility for safe handling of all types of oil based 100% aromatic content and other non aggressive chemicals. 2. Light Weight & Highly Flexible makes it easy to handle in loading and unloading. 3. Tough PVC outer cover resists to dragging, wear, abrasion, UV and ozone resistance having maximum durability and safety. 4. Double end to end electrical continuity prevents static electricity build up and internal arcing. 5. Suitable for 0.9 Bar Vacuum rating. CONSTRUCTION INNER WIRE: High tensile strength galvanized steel OUTER WIRE: High tensile strength galvanized steel CARCASS: Multiple layers of polypropylene fabric, film and polyester barrier layers COVER: Abrasion resistant PVC impregnated fabric TEMPERATURE RANGE: -30°C to +80°C FOR CHEMICAL HOSE: Please refer chemical resistance compatibility chart END FITTING: As per client requirement which will be externally crimped or swaged sAFETY COMPOHOSE™ assemblies are tested at 1.5 times rated W.P for safety & reliability in accordance with BSEN 13765. Manufacturer test certificate will be provided with the supply. Burst pressure Indicated is at ambient temperature. Electrically continuity is achieved by the two wire bonded to the end fitting, this helps dissipate accumulated charge and to avoid static flash

...more

MULTICHEM PTFE DOCK CHEMICAL

HEAVY DUTY-STG Heavy Duty multichem PTFE dock chemical composite hose are ideal for marine services handling wide range of very aggressive Chemicals where additional chemical resistance is needed with PTFE inner layers. APPLICATION The COMPOHOSE™ assembly are recommended for typical loading and unloading barges, ocean tanker and bunkering services also recommended for the other dock side operation at port installation. The spiral wound high tensile Stainless Steel 316 inner wire and Galvanized Iron or Stainless Steel under outer wire for providing strength & flexibility to maintain hose integrity under stress and strain of the ship and barge movement. COMPLIANCE Heavy Duty Multichem PTFE Dock Chemical composite hose are manufactured and tested EN13765 Type 3. PRODUCT HANDLE Very Aggressive or corrosive acid and alkalis, MTBE, Chlorinated hydrocarbons, aromatic fuels, alcohols where PTFE lining is mandatory. Refer to the chemical compatibility chart for specific recommendations. FEATURES 1. Complete product compatibility for safe handling of all types very aggressive Chemicals, solvent, and acids including chloride and fluoride compounds. 2. PTFE Liner with polypropylene and polyester barrier layers for maximum chemical resistance. 3. Tough PVC outer cover resists to dragging, wear, abrasion, UV and ozone resistance having maximum durability and safety. 4. Choice of Galvanized Iron / Stainless Steel 304 / 316 outer wire for maximum durability depending on external environment. 5. Double end to end electrical continuity prevents static electricity build up and internal arcing. 6. Suitable for 0.9 Bar Vacuum rating. CONSTRUCTION INNER WIRE : Stainless Steel 304 / 316 or PVDF Coated OUTER WIRE : High tensile strength galvanized steel or Stainless Steel 304 / 316 CARCASS : Multiple layers of PTFE, polypropylene fabric, film and polyester barrier layers COVER: Abrasion resistant PVC impregnated fabric TEMPERATURE RANGE: -30°C to +100°C FOR CHEMICAL HOSE: Please refer chemical resistance compatibility chart END FITTING: As per client requirement which will be externally crimped or swaged

...more

MULTICHEM PTFE CHEMICAL

HEAVY DUTY-GPG Standard Duty Multichem PTFE Chemical hoses are designed for handling wide range of aggressive chemicals, solvents and acids including chloride and fluoride compounds. PTFE inner layers and other special barrier layers assure maximum product life in application and clean transfer are critical. Electrical continuity is achieved by two wires bonded to end fittings, this helps dissipate accumulated charges to avoid static flash. APPLICATION The COMPOHOSE™ assembly are recommended and designed for in plant transfers. Tank to process Chemical Handling, Storage tank transfer & Rail Wagon loading and unloading of many Aggressive Chemicals, solvents and acids including chloride and fluoride compounds. The spiral wound Stainless Steel 304 / 316 inner wire and Galvanized iron outer wire for providing strength and the flexibility to maintain hose integrity under stress and strain. COMPLIANCE Standard Duty Multichem PTFE Dock Chemical composite hoses are manufactured in accordance to EN13765/2010 Type2. PRODUCT HANDLE Very Aggressive or corrosive acid and alkalis, MTBE, Chlorinated hydrocarbons, aromatic fuels, alcohols where PTFE lining is mandatory. FEATURES 1. Complete product compatibility for safe handling of all types very aggressive Chemicals, solvent, and acids including chloride and fluoride compounds. 2. PTFE Liner with polypropylene and polyester barrier layers for maximum chemical resistance. 3. Tough PVC outer cover resists to dragging, wear, abrasion, UV and ozone resistance having maximum durability and safety. 4. Choice of Galvanized Iron / Stainless Steel 304 / 316 outer wire for maximum durability depending on external environment. 5. Double end to end electrical continuity prevents static electricity build up and internal arcing. 6. Suitable for 0.9 Bar Vacuum rating. CONSTRUCTION INNER WIRE : Stainless Steel 304 / 316 or PVDF Coated OUTER WIRE : High tensile strength galvanized steel or Stainless Steel 304 / 316 CARCASS : Multiple layers of PTFE, polypropylene fabric, film and polyester barrier layers COVER: Abrasion resistant PVC impregnated fabric TEMPERATURE RANGE: -30°C to +100°C FOR CHEMICAL HOSE: Please refer chemical resistance compatibility chart END FITTING: As per client requirement which will be externally crimped or swaged

...more

MULTICHEM CHEMICAL

STANDARD DUTY-GPG Standard Duty multichem chemical composite are designed for handling wide range of very aggressive Chemicals where additional chemical resistance is needed with PTFE inner layers. APPLICATION The COMPOHOSE™ assembly are recommended for Tank to process Chemical Handling, Storage tank transfer & Rail wagon loading and unloading of chemicals. The spiral wound Polypropylene coated galvanized iron outer wire for providing strength & the flexibility to maintain hose integrity under stress and strain COMPLIANCE Standard Duty Multichem Chemical composite hose are manufactured in accordance to BSE EN 13765/2010 Type2. PRODUCT HANDLE Highly corrosive acid and alkalis, aldehydes, amines, aromatic fuels, chlorinated hydrocarbon, alcohols, ketones, lacquers and petroleum products. Not suitable for service for many bromide, chloride or fluoride compounds. Refer to the chemical compatibility chart for specific recommendations. FEATURES 1. Polypropylene liner with heavy duty polypropylene carcass for maximum chemical resistance. 2. Tough PVC outer cover resists to dragging wear, abrasion, UV and ozone resistance having maximum durability and safety. 3. Double end to end electrical continuity prevents static electricity build up and internal arcing. 4. Choice of Galvanized Iron / Stainless Steel 304 / 316 outer wire for maximum durability depending on external environment. 5. Suitable for 0.9 Bar Vacuum rating. CONSTRUCTION INNER WIRE : Stainless Steel 304 / 316 or PVDF Coated OUTER WIRE : High tensile strength galvanized steel or Stainless Steel 304 / 316 CARCASS : Multiple layers of PTFE, polypropylene fabric, film and polyester barrier layers COVER: Abrasion resistant PVC impregnated fabric TEMPERATURE RANGE: -30°C to +80°C FOR CHEMICAL HOSE: Please refer chemical resistance compatibility chart END FITTING: As per client requirement which will be externally crimped or swaged

...more

MULITIOIL DOCK OIL SUCTION

HEAVY DUTY-GPG Heavy duty oil marine hose are designed for handling fuel, lubricant and 100% aromatics at required discharge pressure or suction at port installation. APPLICATION The COMPOHOSE™ assembly are recommended for loading and unloading barges, ocean tanker and bunkering services also recommended for the other dock side operation at port installation. The spiral woung high tensile galvanized iron inner wire and outer wire for providing strength and the flexibility to maintain hose integrity under stress and strain of the ship and barge movement. COMPLIANCE Heavy Duty Marine hoses are manufactured and tested in accordance to EN 13765 type 3 PRODUCT HANDLE Gasoline, Diesel fuel, paraffin, kerosene, lubricaring oils and 100% aromatics as well as black oils and heavy lubricants and solvents. FEATURES 1. Complete product compatibility for safe handling of all types of oil based 100% aeromatic. 2. Tough PVC outer cover resists to dragging wear, abrasion, UV and ozone resistance having maximum durability and safety. 3. Double end to end electrical continuity prevents static electricity build up and internal arcing. 4. Suitable for 0.9 Bar Vacuum rating. CONSTRUCTION INNER WIRE : High tensile strength galvanized steel OUTER WIRE : High tensile strength galvanized steel CARCASS : Multiple layers of polypropylene fabric, film and polyester barrier layers COVER: Abrasion resistant PVC impregnated fabric TEMPERATURE RANGE: -30°C to +80°C FOR CHEMICAL HOSE: Please refer chemical resistance compatibility chart END FITTING: As per client requirement which will be externally crimped or swaged

...more

MULITICHEM DOCK CHEMICAL

HEAVY DUTY-GPG Heavy Duty multichem dock chemical composite hose are ideal for marine services handling wide range of Inorganic & Organic liquids, Chemicals & cargo at port installation. APPLICATION The COMPOHOSE™ assembly are recommended for loading and unloading barges, ocean tanker and bunkering services also recommended for the other dock side operation at port installation. The spiral woung high tensile galvanized iron inner wire and outer wire for providing strength and the flexibility to maintain hose integrity under stress and strain of the ship and barge movement. COMPLIANCE Heavy Duty Multichem Dock Chemical composite hose are manufactured and tested EN13765 Type 3. PRODUCT HANDLE Highly corrosive acid and alkalis, aldehydes, amines, aromatic fuels, chlorinated hydrocarbons, alcohols, ketones, lacquers and petroleum products. Not suitable for service for many bromides, chloride or fluoride compounds. Refer to the chemical compatibility chart for specific recommendations. FEATURES 1. Complete product compatibility for safe handling of all types of Inorganic / organic liquids & other aggressive chemicals in dockside operations. 2. Tough PVC outer cover resists to dragging wear, abrasion, UV and ozone resistance having maximum durability and safety. 3. Choice of High tensile strength galvanized steel / Stainless Steel 304 / 316 outer wire for maximum durability depending on external environment. 3. Double end to end electrical continuity prevents static electricity build up and internal arcing. 4. Suitable for 0.9 Bar Vacuum rating. CONSTRUCTION INNER WIRE : Polypropylene coated galvanized steel or Stainless Steel 304 / 316 OUTER WIRE : High tensile strength galvanized steel or Stainless Steel 304 / 316 CARCASS : Multiple layers of polypropylene fabric, film and polyester barrier layers COVER: Abrasion resistant PVC impregnated fabric TEMPERATURE RANGE: -30°C to +80°C FOR CHEMICAL HOSE: Please refer chemical resistance compatibility chart END FITTING: As per client requirement which will be externally crimped or swaged

...more

LIQUID PETROLEUM GAS / LIQUID NATURAL GAS SERVICE CRYOGENIC

HEAVY DUTY Heavy duty Gas hose are designed especially for transfer of fully refrigerated convey ants like LPG, LNG and their related convey ants in Gas group 4,5,7. APPLICATION The COMPOHOSE™ assembly are recommended for fully refrigerated liquefied petroleum gasses and related conveyants in Gas group 4,5,7. The spiral wound Stainless Steel 316 inner wire and Stainless Steel 316 under wire for providing strength & the flexibility to maintain hose integrity under stress and strain. COMPLIANCE Gas hose are manufactured and tested in accordance EN 13766 Class A Type 1. PRODUCT HANDLE Gas hoses are suitable for transfer Ammonia, LPG, LNG, CNG, Liquid Nitrogen, Propane, Butadiene, Butylenes, Dimethylamide, Ethylamine, Ethyl Chloride, Methyl Acetylene, Methyl Bromide Propane Propadiene, Propylene, Vinyl Chloride, Refrigerant Gases. LPG While Composite hose are suitable for : Liquid Ethylene at -105°C, Liquid Ethane at -88°C. FEATURES 1. Maximum compatibility – handles a wide range of low temperature and cryogenic conveyants. 2. Reliability – Tested to industry standards 1 ½ time the rated working pressure. 3. Durability – Heavy duty Stainless Steel 316 inner and outer wire for maximum chemical and wear resistance. 4. Double end to end electrical continuity prevents static electricity build up and internal arcing. 5. Suitable for 0.9 Bar Vacuum rating. CONSTRUCTION INNER WIRE : Stainless Steel 304 / 316 OUTER WIRE : Stainless Steel 304 / 316 CARCASS : Multiple layers of polypropylene fabric, film and polyester barrier layers COVER : Polyamide fabric TEMPERATURE RANGE: -196°C to +50°C END FITTING: As per client requirement which will be externally crimped or swaged

...more

Klipco Worm Drive Hose Clips

General uses Automotives, Trucks, Tractors, & Two Wheelers Aircrafts, Space & Satellites Atomic Plants Air Conditioning Engineering, Machine Toos, & Pneumatics Hydraulic & Pneumatics Laboratories Marine Navy & Defense Mines Oil, Gas & Refinery Plants- Steel, Chemical, Fertilizers Cement etc. Plantations, Agriculture & Domestic Railway & Metros Sewage Treatment Plants Traffic, Signals & Hoardings

...more

HIGH PRESSURE HOSE - R1

Be first to Rate

Rate ThisOpening Hours