Simplex Design

We manufacture and supply top quality heating and pumping units, which are made from qualitative components procured from the most well known vendors. These are custom designed to meet the requirement of our customers. Our heating and pumping units are applicable to deliver heavy viscosity fuel oils to furnaces, kilns, oven, dryers, boilers etc at a pressure of 15-20 psi and at a temperature of 90-100°C and near burner tip. Apart from this, our fuel oil handling system minimizes start up difficulties and reduces maintenance costs. The Pumping and Heating Units are supplied in the following three models : Simplex Design :Consists of 1 Motorised rotory gear pumps, Preheater and 2 Simplex filterDuplex (1) Design :Consists of 2 motorised rotory gear pumps 1 preheater and 1 duplesDuplex (2) Design :Consists of 2 motorised rotory gear pumps, 2 preheater and 2 duplex filter. The Pumping and Filtering Units are Supplied in the Following Three Models : SIMPLEX DESIGN : Cnsists of 1 motorised rotory gear pumps, 1 simplex suction filter and valves, Interconnecting pipe line.DUPLEX DESIGN : Consists of 2 motorised rotory gear pump, 1 duplex suction filter and valves, interconnecting pipe line.SIMPLE DESIGN : Consists of 1 motorised rotory gear pump, 1 simplex suction filter, 1 By-Pass valve, Pressure gauge, Interconnecting pipe line. Capacities : VINAYAK's Pumping and heating units are supplied in various capacities depanding on the total oil Consumption in the burners to be pump and preheat. The following table gives the maximum amount of oil which can be heated by unit of a particular size. Special Type of Heating and Pumping Units Suitable for Thermic Fluid : 1 motorized rotary gear pump (suitable for handling oil at 300 Deg.c)1 oil pre heater1 delivery side simplex filter valvesInterconnecting pipelineCommon base tray Applications : For Oil Fired Furnaces KWLiters per Hrs.20oC30oC40oC50oC60oC70oC80oC90oC100oC110oC120oC17047352823201816141312214094705646403632282624321014110584696054484239364280188140112928072645652486420282210168138120108968478729630423315252207180162144126117108128405644203362762402161921681561441611207525604483683202882562242081921812608466305044143603242882522342162416801128840672552480432384336312288362520169212601008828720648576504468432

...more

Sensitrol Oil Valve

We are one of the leading manufacturers and suppliers of sensitol oil valves in India. Our exquisite array of Oil Valve is engineered using optimum quality raw material. Designed in compliance with international quality standards. Our sensitrol oil valves are suitable for precise oil flow control to maintain oil and combustion air ratio more accurate at the burner tip., Sensitrol oil valves are fabricated of forged brass body and inside parts hardened steel and spring loaded handle to prevent accidental oil setting. Availability : Model : VI-1, VI-2, VI-3, VI-4Oil Flow : 10, 20, 40, 80 Raw Materials Used : Forged brass bodyInside parts hardened steelSpring loaded handle Applications : For Oil Fire Burner

...more

Ratiotrol Oil Valve

We are one of the leading manufacturers and suppliers of quality oil valves that are suitable for precise oil flow control to maintain oil flow more accurately and in proportion to combustion air. Our oil valve is fabricated of cast aluminum body and rubber diaphragm of nitrayl or viton rubber to withstand oil temperature up to 120 deg c. Our oil valves are operated with the help impulse air signal from combustion main air supply. Increase in the impulse air pressure will increase oil flow proportionately. Our oil valves are provided with female thread for inlet and outlet oil pressure gauge and impulse air pressure gauge. Attributes : Strong builtCorrosion resistantEfficientAbrasion resistantControls oil flowAccurate and in proportionFemale thread with inletoutletImpulse air pressure Raw Materials Used : Cast aluminum body andRubber diaphragm of nitraylViton rubber Availability : Model : VIR-1, VIR-2Air Impulse : 200 MM, 1000 MMOil flowRate LPH : 30, 360 Applications : For Oil Fired Furnaces

...more

Pumping Unit

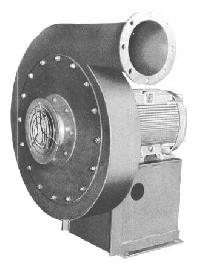

Pressure Blower

Our pressure blowers are generally direct driven type, i.e. impeller is directly mounted on the shaft of standard TEFC 3 Phase electric motor, running at 2880 RPM. Our Combustion air blowers are fabricated from heavy gauge mild steel sheets and structural. The impeller is mostly of riveted construction and is carefully balanced, statically and dynamically to obtain a perfectly vibration free running. The impellers may be of M.S., and S.S. grade aluminum. The inlet to the blower is generally open to atmosphere but provided with safety cover. Easy removal of the impeller for maintenance purposes is facilitated by providing large inlet cover on the inlet side. Combustion blowers can also be supplied with �V� � Belt drive arrangement or drive through flexible coupling when required. Combustion or Pressure Blowers : These are generally direct driven type, i.e impeller is directly mounted on the shaft of standard TEFC 3 Phase electric motor, running at 2880 RPM, These blowers are mainly used for the following applications : For fuel firing : That is to supply requisite amount of air at constant pressure for the proper atomization and complete combustion of oil in the burners. To supply combustion air to foundry cupolas. Forced air cooling of products.Forced air conveying systems. Liquid agitation, etc. Vinayak�s combustion air blowers are fabricated from heavy gauge mild steel sheets and structural. The impeller is mostly of riveted construction and is carefully balanced, statically and dynamically to obtain a perfectly vibration free running. The impellers may be of M.S., and S.S. grade. Aluminum. The inlet to the blower is generally open to atmosphere but provided with safety cover. Easy removal of the impeller for maintenance purposes is facilitated by providing large inlet cover on the inlet side. Combustion blowers can also be supplied with �V� � Belt drive arrangement or drive through flexible coupling when required. Characteristic curves and standard range of our blowers : Vinayak�s combustion blowers are available from 1 to 200 H.P. with discharge capacities from 100 CFM to 12000 CFM (160 to 1000 m3/hr) and pressures from 4� to 64� SWG (100 to 18000 mm SWG). Properties : StrongRobustDurableCorrosion resistantAbrasion resistant Raw Materials Used : Heavy gauge mild steel sheetsStructural Steel sheets Product Features : Impeller is of riveted construction is carefully balancedStatically and dynamically to obtain a perfectly vibration free runningMade of M.S., and S.S. grade. aluminumThe inlet to the blower is generally open to atmosphereProvided with safety coverEasy removal of the impeller for maintenance purposesProvides large inlet cover on the inlet sideCombustion blowers can also be supplied with �V� � Belt drive Applications : Chemical & Pharma CompanyHotelsSteel Manufacturing IndustriesNon- Ferrous metal Manufacturing IndustriesAllied Industries

...more

Melting Furnace - 03

We are recognized as a prime Manufacturer and Supplier of Melting Furnace - 03, which is offered in different types and capacities. The Aluminum Melting Furnaces are made available along with pollution control unit that helps in maintaining a clean environment. We also undertake erection commissioning and installation of dross processing, aluminum alloy and aluminum extrusion plant, providing one month production training. Types Available : Rotary aluminum melting furnaceCrusible furnace (stationery or tilting type)Skelner furnace Features : High fuel efficiencyTilting arrangement: Manual or hydraulicRobust construction Long functional lifeCost-effective Construction : Furnace shell: Ms 6810 mm thick :First layer of mill board Second layer insulation bricks Third layer of 70 % alumina bricks Capacities : Crusible max. : 800 kgSkelner max. : 10,000 kgRotary max. : 5000 kg

...more

Melting Furnace - 02

We are Recognized as a Prime Manufacturer and Supplier of melting Furnace - 02, Which is Offered in Different Types and Capacities. the Aluminum Melting Furnaces are Made Available Along with Pollution Control Unit that Helps in Maintaining a Clean Environment. We also Undertake Erection Commissioning and Installation of Dross Processing, Aluminum Alloy and Aluminum Extrusion Plant, Providing One Month Production Training. types Available : rotary Aluminum Melting Furnacecrusible Furnace (stationery or Tilting Type)skelner Furnace features : high Fuel Efficiencytilting Arrangement: Manual or Hydraulicrobust Construction long Functional Lifecost-effective construction : furnace Shell: Ms 6810 Mm Thick :first Layer of Mill Board second Layer Insulation Bricks third Layer of 70 % Alumina Bricks capacities : crusible Max. : 800 Kgskelner Max. : 10,000 Kgrotary Max. : 5000 Kg

...more

Melting Furnace - 01

We are Recognized as a Prime Manufacturer and Supplier of melting Furnace, Which is Offered in Different Types and Capacities. the Aluminum Melting Furnaces are Made Available Along with Pollution Control Unit that Helps in Maintaining a Clean Environment. We also Undertake Erection Commissioning and Installation of Dross Processing, Aluminum Alloy and Aluminum Extrusion Plant, Providing One Month Production Training. types Available : rotary Aluminum Melting Furnacecrusible Furnace (stationery or Tilting Type)skelner Furnace features : high Fuel Efficiencytilting Arrangement: Manual or Hydraulicrobust Construction long Functional Lifecost-effective construction : furnace Shell: Ms 6810 Mm Thick :first Layer of Mill Board second Layer Insulation Bricks third Layer of 70 % Alumina Bricks capacities : crusible Max. : 800 Kgskelner Max. : 10,000 Kgrotary Max. : 5000 Kg

...more

Magnetic Separator

We are a Prominent Manufacturer of magnetic Separator. the Magnetic Separator is Specially Designed to Meet a Wide Range of Application. the Permanent Magnetic Drum Consists of a Stationery Permanent Magnetic Assembly, Having Uniform Magnetic Field Across the Entire Width of Drum and Half the Circumference. as the Material is Fed Evenly from the Hopper and Then Falls On the Vibrating Chute and is Uniformly Spread Across the Drum Length. Strong Magnetic Field Attracts and Holds Ferrous Particles Revolving Shell. as the Revolving Shell Carries the Iron Particle Through the Stationery Magnetic Field and Non-magnetic Particles Fall Freely from the Shell, the Magnetic Material Carried with Rotating Shell Falls After Magnetic Field Finishes the Limit On Rotation Shell. constituents permanent Magnet, non-magnetic Stainless Steel, gear Motor range 300 Mm, 400 Mm, 450 Mm, 500 Mm, 600 Mm, 800 Mm

...more

Low Air Pressure Burner

We are known as one of the most prominent low pressure burner manufacturers and suppliers in India. Our durable low air pressure burner has been designed to operate & burn light & heavy grades of fuel oils using only low pressure air and oil. Perfect oil atomization is obtained without the use of compressed air or high pressure oil. The heavy oil needs to be preheated to obtain the correct viscosity before being passed through the burner. The construction of the burner is robust with cast iron bodies giving them durability in the high temperature operations. Our low air pressure burner complete with air and oil control valve is suitable for only oil and can be used with pumping system as well as gravity feed system. Product Features : Separate Air and oil control valvePumping system as well as gravity feed systemOil pressure between 1 kgcm2 to 2 kgcm2Air pressure should be between 500 mm to 800 mm SWG Application : For Oil Combustion Uses : Industrial heatingHousehold heating

...more

Induced Draft Blower

Our induced draft blowers are high volumetric and are generally used to handle hot gases or hot air. Below 80°C, the blowers may be direct driven type, but above this they are either belt driven or driven through flexible couplings. Induced draft blowers can be supplied in M.S., S.S. construction. These are high volumetric but low pressure blowers generally used to handle hot gases or hot air. Below 80°C, the blowers may be direct driven type, but above this they are either belt driven or driven through flexible couplings. Induced draft blowers can be supplied in M.S., S.S. construction. Mild Steel is suitable for working upto 300°C, whereas with S.S. construction, they can be used upto 600°C with �V� belt or flexible drive, and with water cooled bearings they can work satisfactorily at as high as 1000°C. The impellers are in welded construction and are statically & dynamically balanced. Vinayak�s also makes SPECIAL BLOWERS for extra high temperatures upto 1000°C, in which bearings and shaft are continuously cooled with running water. Oil lubrication for the bearings also can be provided. Different sizes are available to suit individual requirements of customers in M.S. and / or S. S. construction with horizontal or vertical mounting arrangement. Sizes Available : ½ H.P. to 100 H.P. capacities1, 60,000 CFM (2,75,000m³/hr )Static pressures of 25 to 300 MMWG ( 1� to 12� WG) Product Features : 720, 960, 1440 and 2880 RPMDirect drive and flexible coupling drives�V� � belt drive arrangementInfinite speed combinationsExtra high temperatures up to 1000°Oil lubrication for the bearings is provided Applications : Chemical & Pharma CompanyHotelsSteel Manufacturing IndustriesNon- Ferrous metal Manufacturing IndustriesAllied Industries

...more

Gas Limiting Orifice Valve

We offer the most efficient quality Limiting Orifice Gas Valves in India. Orifice Gas Valves are designed to allow precise setting of high fire for fine control of gas flow. Limiting orifice valve are designed for adjusting gas flow to the burner tip to maintain accurate gas-air ratio. These are simple and easy to use. Limiting orifice valves are provided with "v" port plug which can be adjusted with screw provided on top with safety cover. These valves are suitable for LPG , CNG, and Producer Gas. Raw Materials Used : Forged brass body partsInside brass parts Product Features : Set screw provided to be operated by screw driverFine tuning of gasExtra cap above set screw to prevent leakageDurableCorrosion resistantWith stopper cap Applications : FurnacesGas stations

...more

Dust Collector

We are the prominent manufacturer, supplier and exporter of Dust Collector Unit, which is the most economical and effective solution for assorted range of dust collection. Dust collectors are simple, low cost and efficiently designed for high performance. Dust collectors are mainly consist of following part. Blower unitSilencerFilter bag unitHopperDust collection unit Working Principle : Contaminated air from dust generation source is drawn through the inlet provided at the bottom of hopper where heavy particle lost there velocity and dropped into the dust bin. Light particle get deposited on outer surface of filter bag and only clean air get exhausted through blower to atmosphere. Application : Chemical and allied industriesRubber and plastic IndustriesPharmaceutical industriesFood and related industriesTextile IndustriesAgriculture industriesWood processing industriesIron processing industries. Benefits : Simplified MaintenanceLow capital costMinimization of safety hazardousLow operating and energy

...more

Duplex Design

We manufacture and supply top quality heating and pumping units, which are made from qualitative components procured from the most well known vendors. These are custom designed to meet the requirement of our customers. Our heating and pumping units are applicable to deliver heavy viscosity fuel oils to furnaces, kilns, oven, dryers, boilers etc at a pressure of 15-20 psi and at a temperature of 90-100°C and near burner tip. Apart from this, our fuel oil handling system minimizes start up difficulties and reduces maintenance costs. The Pumping and Heating Units are supplied in the following three models : Simplex Design :Consists of 1 Motorised rotory gear pumps, Preheater and 2 Simplex filterDuplex (1) Design :Consists of 2 motorised rotory gear pumps 1 preheater and 1 duplesDuplex (2) Design :Consists of 2 motorised rotory gear pumps, 2 preheater and 2 duplex filter. The Pumping and Filtering Units are Supplied in the Following Three Models : SIMPLEX DESIGN : Cnsists of 1 motorised rotory gear pumps, 1 simplex suction filter and valves, Interconnecting pipe line.DUPLEX DESIGN : Consists of 2 motorised rotory gear pump, 1 duplex suction filter and valves, interconnecting pipe line.SIMPLE DESIGN : Consists of 1 motorised rotory gear pump, 1 simplex suction filter, 1 By-Pass valve, Pressure gauge, Interconnecting pipe line. Capacities : VINAYAK's Pumping and heating units are supplied in various capacities depanding on the total oil Consumption in the burners to be pump and preheat. The following table gives the maximum amount of oil which can be heated by unit of a particular size. Special Type of Heating and Pumping Units Suitable for Thermic Fluid : 1 motorized rotary gear pump (suitable for handling oil at 300 Deg.c)1 oil pre heater1 delivery side simplex filter valvesInterconnecting pipelineCommon base tray Applications : For Oil Fired Furnaces KWLiters per Hrs.20oC30oC40oC50oC60oC70oC80oC90oC100oC110oC120oC17047352823201816141312214094705646403632282624321014110584696054484239364280188140112928072645652486420282210168138120108968478729630423315252207180162144126117108128405644203362762402161921681561441611207525604483683202882562242081921812608466305044143603242882522342162416801128840672552480432384336312288362520169212601008828720648576504468432

...more

Dual Fuel Burner

Vinayak industries high pressure burners are widely used on heat treating and melting furnaces, incinerators, chemical process equipment. High pressure burners are provided with C.I. front mounting plate, 1 no. primary butterfly valve, 1 no. secondary butterfly valve, 1 no. gun metal micro valve for fine oil control, 1 no. air body. High pressure burners are Duel Fuel Burner suitable for light oil, heavy oil and gas. Required air pressure between 800 mm to 1000 mm swg.Required oil pressure between 1.5 to 3.5 kg and cm Above burners can be provided with spark plug, pilot burner, burner block, P.I.D. control for Low fire and high fire. Product Features : Primary and secondary air butterfly valvesFor light oil /heavy oil and CNG/LPG gasOil pressure between 1.2kg/cm2to 3 kg/cm2Air pressure between 700 mm SWG to1000 mmHighly durableCorrosion resistantAbrasion resistantStable flame Applications : For Oil Fired Furnaces Uses : Industrial heatingHousehold heating

...more

Cyclone Separator

Vinayak�s Cyclone Separator is simple, low cost and efficiently designed for high performance. These are generally used for removing dry solid particle from air without the use of filters through vortex separation. We offer high quality Cyclone Separator that is appreciated by our clients across the globe. They are mainly divided into two classes: Single cycloneMultiple cyclone Working Principle : High speed rotating (air) flow is established within a cylinder and conical container to separate mixtures of solids and fluids. Air flows in a spiral pattern, beginning at the top inside the cylindrical shape and ending at the bottom inside the conical shape. Solid particle losses its velocity before exiting the cyclone from the top and solid particle gets collected at the bottom , only clean air exit from the center. Application : Rubber industriesPlastic IndustriesPharmaceutical industriesFood and related industriesChemical industries Benefits : Removing dry solid particle from air the use of filtersEasy to useLow operating cost

...more

Air Blower

heating unit

Oil Filter

Oil Burner

Gas Burner

Butterfly Valve

recirculation fan

pressure blower induced draft blower

Be first to Rate

Rate This