Slat Conveyor 02

Our Slat Conveyors are constructed out of high quality materials and are custom built. We offer robust Slat Conveyor Chains, which are available in different configuration. They are designed to handle heavy materials. The chains offer frictionless movement. Our range of slat conveyors consist one or more of numerous chains to which non overlapping, non-interlocking spaced slats of wood or flanged metal are attached to form a traveling table for the objects to be conveyed for various applications. Features 10 to 20 cm wider than the diagonal length of the largest object to be carried.Pusher cleats are provided at regular intervals to facilitate inclined conveyingRobust & DurableRobustly builtEasy to operateSimple to installSmooth runningConsist of one or more moving chainsAdjustable guide railsStandard & GMP modelsFixed or variable speed Widely Used In Various industrial material handling applicationsAssembly linesChemical industryConveying regular shaped container

...more

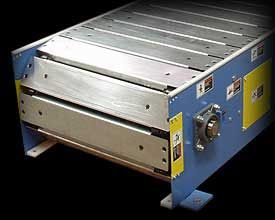

Slat Conveyor 01

Our Slat Conveyors are constructed out of high quality materials and are custom built. We offer robust Slat Conveyor Chains, which are available in different configuration. They are designed to handle heavy materials. The chains offer frictionless movement. Our range of slat conveyors consist one or more of numerous chains to which non overlapping, non-interlocking spaced slats of wood or flanged metal are attached to form a traveling table for the objects to be conveyed for various applications. Features 10 to 20 cm wider than the diagonal length of the largest object to be carried.Pusher cleats are provided at regular intervals to facilitate inclined conveyingRobust & DurableRobustly builtEasy to operateSimple to installSmooth runningConsist of one or more moving chainsAdjustable guide railsStandard & GMP modelsFixed or variable speed Widely Used In Various industrial material handling applicationsAssembly linesChemical industryConveying regular shaped container

...more

Screw Conveyor 02

Our Screw Conveyors are designed to efficiently convey a wide variety of materials in both horizontal and inclined path. We offer a broad array of sizes to select from that fit almost all types of applications. Materials that are extremely abrasive for being transferred through screw conveyor can be elevated in a Screw-Lift Conveyor efficiently with less damage caused.

...more

Screw Conveyor 01

Our Screw Conveyors are designed to efficiently convey a wide variety of materials in both horizontal and inclined path. We offer a broad array of sizes to select from that fit almost all types of applications. Materials that are extremely abrasive for being transferred through screw conveyor can be elevated in a Screw-Lift Conveyor efficiently with less damage caused.

...more

Rotary Airlock Valve

Rotary Air Lock Valve are important components of pneumatic conveying systems. Rotary airlock is also known as rotary valve, rotary feeder or airlock feeder. The basic use of the rotary airlock valve is as an airlock or sealing pressurized systems against loss of air or gas while maintaining a flow of material between components with different pressure. We Manufacture Rotary Air Locks used for feeding materials under vacuum or pressure while sealing in air & gas. Principle of gravity is used for dropping the material in the container. This is done with the help a vane rotor. The rotor consists of a no of Vanes and is available in different diameters as per the requirement of the process. The rotary air lock consists of rotor with minimum clearance of 0.5mm between van tip & interior of body. This is done to ensure perfect air locking considering the wear & tear of the rotors are driven with the help of standard motor & gearboxes. Our Rotary Air Lock Valves have high filling efficiency due to effective inlet shape and close running clearances. Our Rotary Airlock valves have wide application in industry wherever dry free-flowing powders, granules, crystals, or pellets are used. Typical materials include: Chemicals, Dyes, minerals, grains, plastics, dust, fly ash, flour, gypsum, lime, coffee, cereals, pharmaceuticals, etc. Application Areas Silo Discharge : The rotary valve placed under the silo or dust collection system is used to control the bulk solid discharge.Dosage Control : By controlling the rotation speed of the airlock feeder, volumetric metering and dosing of granular solids is achieved.Pneumatic Transportation : The airlock mounted under a cyclone is used for discharging the cyclone. Rotary valves mounted under cyclones, silos or hoppers are used to feed the pneumatic conveying line. Construction Carbon steelStainless steelCI castingsPneumatic Conveying SystemsAir Pollution Systems, PowderConveying systems

...more

positive displacement blowers

Positive-displacement blowers have rotors, which "trap" air and push it through housing. Positive-displacement blowers provide a constant volume of air even if the system pressure varies. They are especially suitable for applications prone to clogging, since they can produce enough pressure - typically up to 1.25 kg/cm2 - to blow clogged materials free. They turn much slower than centrifugal blowers (e.g. 3,600 rpm), and are often belt driven to facilitate speed changes. Specifications Output Power : 0.2 Kw To 7.5 Kw Max Flow : 530 M3/Hr (312 Cfm) Max Pressure : 570 Mbar (228 In H2o) Max Vacuum : 440mbar (174 In H2o) Stages : Single/Double Electrical 220 Vac, 50 Hz, Single Phase 440 Vac, 50 Hz, Three Phase Features The Ring Blowers are suitable for all those applications requiring considerably higher pressure. Side Channel exhausters are used in all those applications requiring an operating vacuum higher than the one achievable by a fan, but not as to require the use of a vacuum pump. The rotating parts are not in contact with the casing. Therefore, no friction during operation and thus no internal lubrication is necessary. The other main features are: Higher pressure ratio 100% oil-free air Low noise level (65dba Normal, 85 dba Max.) 140% Overload protection ±10% Voltage fluctuation tolerance Rated for continuous duty IP 54 Protection Class F insulation Pressure die casted body, impeller & rotar Low temperature rise No, vibration, and therefore complete Pulsation- free discharge Cooler running, double sealed NSK (Japan) bearings Applications The Ring Blowers are suitable for very wide field of application some of them are: Pneumatic conveying of solids/liquids Vacuum transfer of components/sheets Blowing away debris/sucking away debris Sorting/counting of cards/envelopes/papers To suck debris/gases from clean rooms/enclosed spaces/tunnels/laboratories To agitate and aerate water in spa/whirlpool/swimming pool/fishing tanks/aqua culture tanks Furnace fuel burning Beverage bottling/labeling drying Medical/dental suction units Operating Principle The Blower includes an impeller and a side channel formed with a semi-circular side wall, having an inlet and outlet. As the impeller rotates, the air between the impeller blades is radially and circumferentially accelerated and pushed into the side channel. Here it is further compressed and forced back towards the impeller blades where the air is further accelerated. As air is transported along a spiral path through the impeller and side channel, each impeller blade increases the compression and acceleration until the air reaches the point where the side channel is connected to the discharge flange, where it is discharged. This type of blower is also referred to by other names such as Regenerative blower, Ring Compressor, Side channel blower or Vortex Blower. The ring blower or exhauster increases the pressure of the aspirated gas by the creation, in the peripheral torodial channel, of a series of vortexes caused by the centrifugal thrust of the impeller. While the impeller is rotating, the vanes force the gas forward and, because of the centrifugal thrust, outwards, producing a helical motion. During this motion, the gas is recompressed repeatedly with a consequent linear pressure increase along the length of the channel. Applications and advantages Ring blowers are suitable for all those applications requiring considerably higher pressures than that which can be achieved using centrifugal fans. Side channel exhausters are used in all those applications requiring an operating vacuum higher than the one achievable by a fan, but not as high as to require the use of a vacuum pump. The rotating parts are not in contact with the casing. There is therefore no friction during operation and thus no internal lubrication is necessary. The gas moving through the machine therefore remains uncontaminated and completely oil-free. The Other Main Features Are Beautiful surface Easy installation Low noise level No vibration and therefore complete dynamic Pulsation free discharge Minimal maintenance Higher pressure ratios Cooler running bearings Longer grease life Simple maintenance 100% oil free air Suitable to environment protection Small dimension

...more

Gravity & Powerised Roller Conveyor 02

We offer a wide range of self-gradient Gravity Roller Conveyor to help reduce the manpower requirement in transferring machines and heavy & bulky materials. Our range of automatic motorized conveyors operated with the help of gear drive provides smooth allocation of goods. The Gravity & Powerised Roller Conveyor can also be provided with sensing mechanism for automatic start up and stoppages. Features DurableSturdySmooth runningEasy to operateEasy to install Used to Separate pellets by sorting undersizeOversize pellets separately

...more

Gravity & Powerised Roller Conveyor 01

We offer a wide range of self-gradient Gravity Roller Conveyor to help reduce the manpower requirement in transferring machines and heavy & bulky materials. Our range of automatic motorized conveyors operated with the help of gear drive provides smooth allocation of goods. The Gravity & Powerised Roller Conveyor can also be provided with sensing mechanism for automatic start up and stoppages. Features DurableSturdySmooth runningEasy to operateEasy to install Used to Separate pellets by sorting undersizeOversize pellets separately

...more

gravity powered roller conveyor

Chip Conveyor

Chip Conveyor 02

Our Chip Conveyors are of various configurations and designs. They are tailor-made keeping in mind user�s plant layout and the kind and volume of chips required to be conveyed. Special design chip conveyors are available for handling large volume of metallic wastes.

...more

Chip Conveyor 01

Our Chip Conveyors are of various configurations and designs. They are tailor-made keeping in mind user�s plant layout and the kind and volume of chips required to be conveyed. Special design chip conveyors are available for handling large volume of metallic wastes.

...more

Centrifugal Blower

Centrifugal blowers are more like centrifugal pumps than fans. The impeller is typically gear-driven and rotates as fast as 15,000 rpm. In multi-stage blowers, air is accelerated as it passes through each impeller. In single-stage blower, air does not take many turns, and hence it is more efficient. Centrifugal blowers typically operate against pressures of 0.35 to 0.70 kg/cm2, but can achieve higher pressures. One characteristic is that airflow tends to drop drastically as system pressure increases, which can be a disadvantage in material conveying systems that depend on a steady air volume. Because of this, they are most often used in applications that are not prone to clogging. Specifications Capacity starting from :150 M3/hr / -1.50,000 M3/hrThe pressure range varies between :10 / -1500 mm Wg Features Maximum efficiencyMinimum conveyingHigh performingDurableCompact design

...more

Catering Equipment

Bucket Elevator

We offer an innovative wide range of Bucket Elevators, used to carry bulk raw materials where continuous vertical lifting is required. Bucket Elevators are divided into two classifications namely Centrifugal Bucket Elevator and Continuous Bucket Elevator. The buckets are mounted on chain or Belt as per the requirement. Our Bucket Elevators are available in varying bucket sizes & shapes for meeting customized requirements. The buckets are mounted on either belt or chain to allow free flow of material at loading and discharge points. Most elevators are completely enclosed for controlling dust . A holdback device is provided to prevent the reversal of the bucket-line in case of power interruption. Take up arrangement is provided at the foot-shaft. Selection of bucket elevator and its components such as bucket, belt or chain, take up arrangements, etc., are of prime importance, and depend upon the capacity and the physical and chemical attributes of the material to be conveyed.

...more

Belt Conveyor 02

We manufacture a wide range of Belt conveyors These are strong, efficient and durable. Flat belt conveyors are mainly used for conveying light- and medium weight loads. They are especially useful when the conveying path is inclined � upwards or downwards. The belt is either roller or slider bed supported. For small and irregular shaped items, slider bed is used. For others roller support is effective. Our standard belt conveyors come with suitable carrying Idlers rubber lagged type with grease packed sealed for life time having suitable ball bearings of ample capacity. Suitable troughing angles are selected. Appropriate sealing arrangements for dusty & corrosive atmosphere, ensuring no friction, low wear & tear, and no heat generation. Similarly, are pressed suitable return and guide rollers. Belting specification of our belt conveyors is based on design calculation for drive unit. For ensuring smooth, efficacious & effective working, our belt conveyors are provided with customized Self Aligning Return Roller Frame, Self Aligning Troughing Roller Frame , Return Roller bracket, Troughing Roller Frame & Impact idlers. Head Pulley, Tail Pulley and Bend pulley/ Snub Pulley, etc., are all statically balanced. External & Internal belt cleaners are provided for cleaning the upper surface of the belt after the discharge of the material from the pulley Protected screw type tensioning arrangement is provided with sufficient travel for tensioning of the belt. Tapered skirt board is provided to train and settle the material centrally into the belt. Stringer, Decking plate and Supporting stands are suitably designed and fabricated from standard materials. Each belt conveyor is also provided as required with wire rope switch,, PVC pull cord switch, belt sway switch and zero speed switch on head pulley. Roller type hold back mechanism having sufficient torque rating integral with reduction gear unit are provided where required. Attributing an extra importance, we bring best designed conveyors in keeping with the functional needs.

...more

Belt Conveyor 01

We manufacture a wide range of Belt conveyors These are strong, efficient and durable. Flat belt conveyors are mainly used for conveying light- and medium weight loads. They are especially useful when the conveying path is inclined � upwards or downwards. The belt is either roller or slider bed supported. For small and irregular shaped items, slider bed is used. For others roller support is effective. Our standard belt conveyors come with suitable carrying Idlers rubber lagged type with grease packed sealed for life time having suitable ball bearings of ample capacity. Suitable troughing angles are selected. Appropriate sealing arrangements for dusty & corrosive atmosphere, ensuring no friction, low wear & tear, and no heat generation. Similarly, are pressed suitable return and guide rollers. Belting specification of our belt conveyors is based on design calculation for drive unit. For ensuring smooth, efficacious & effective working, our belt conveyors are provided with customized Self Aligning Return Roller Frame, Self Aligning Troughing Roller Frame , Return Roller bracket, Troughing Roller Frame & Impact idlers. Head Pulley, Tail Pulley and Bend pulley/ Snub Pulley, etc., are all statically balanced. External & Internal belt cleaners are provided for cleaning the upper surface of the belt after the discharge of the material from the pulley Protected screw type tensioning arrangement is provided with sufficient travel for tensioning of the belt. Tapered skirt board is provided to train and settle the material centrally into the belt. Stringer, Decking plate and Supporting stands are suitably designed and fabricated from standard materials. Each belt conveyor is also provided as required with wire rope switch,, PVC pull cord switch, belt sway switch and zero speed switch on head pulley. Roller type hold back mechanism having sufficient torque rating integral with reduction gear unit are provided where required. Attributing an extra importance, we bring best designed conveyors in keeping with the functional needs.

...more

Apron Conveyor

Our Apron Conveyors are engineered for heavy-duty operations. They are custom built to suit the varying requirements of capacity, size, and the material to be handled. Its basic feature is adjustable motor drive speed. Our conveyors can withstand heavy impact load and are abrasion proof. Different type of feeders can handle practically any ores, sand gravel, stone, coal, foundry, and industrial refuse. Apron feeders are recommended for handling materials containing large, heavy or lumps, sharper for installations where they must withstand the impact of heavy materials falling some distance and for receiving and feeding hot materials that would damage other types of feeders. Aprons have wide styles. Characteristics Withstand heavy impact loadAbrasion proofEngineered for heavy-duty operationsAdjustable motor drive

...more

Engineering Equipment

Fabrication Equipment

installation equipment

Belt Conveyor

Blowers

Industrial Conveyors

Turnkey Project Agencies

Be first to Rate

Rate ThisOpening Hours