Roof Waterproofing

Get Price Quote

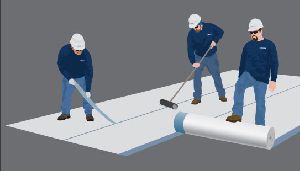

Roof is an important part of any structure, so we need some measurements to protect it. Roof is an important part of any structure that protects us from different weather conditions. But it is also directly affected by the sunlight, wind and rain so we need some measurements to protect it. We provide you mean which ensures that water is carried away from the building without causing any dampness in walls or roofs. Before applying waterproofing materials to roofs we prepare the surface of roof for waterproofing by cleaning, washing and removing dust, oil and grease. We apply multiple coats of waterproofing co-polymer and cementitious waterproofing materials to gain the thickness of membrane. We mainly use liquid applied membrane (LAM) as it is not affected by weather conditions like humidity, rain or extreme hot weather. We also use Pre-formed sheet membranes if needed. It is the polymer-modified bitumen membranes and it is applied by heat. They have recovery properties which make them suitable for contraction and expansion of a building in fluctuating temperature. We also apply insulation on a roof of the building which keeps the building cold in hot weather. Insulation saves money as air conditioners will not be used much. We also take steps to protect insulation by applying vapor retarder such as plastic sheets between roof deck and insulation. We then apply roof membrane over insulation to make a roof system watertight.

Roof Waterproofing Coating

Get Price Quote

TERRACE / ROOF WATERPROOFING BASED ON MEMBRANE COATING SYSTEM ZC-ROOF GFM is designed to protect surface of the building terrace & roof from water & weathering effect. It is developed for complex/critical applications where conventional waterproofing/ weatherproofing products cannot be used or applied. In these areas waterproofing products like polymer admixtures, repellent, adhesives, general purpose coating and sealants do not perform effectively for long time. In such applications the product should withstand heat, UV effects, expansion & contraction, gravity settlements, shrinkage and ageing effects. The product should be long lasting & should remain elastomeric and active permanently. Applications Substrates material : Cementitious substrates, asbestos cement, insulation materials, metal substrates, wood & plywood, bricks & stones, slates & tiles, plastics, bituminous coatings, paints, mastics, asphalt & felt. Substrate/structure types : Concrete/plastered roofs & walls, corrugated sheets, terrace gardens, parapets & chhajjas, drain sections, expansion joints, ventilation outlets, J hooks & screw overlaps, lighting fixture mountings, roofing junctions Type of construction : Residential buildings, commercial buildings, Manufacturing units, malls, warehouses, nuclear power structures, theatres. Components of the System : ZC-Sealcoat :Acrylic based elastomeric high performance coating emulsion. It is single component and ready to use formulation with quick drying properties. It is water repellent with toughness to arrest leakage and seepage of water. It protects the surface of UV radiation. It has got excellent adhesion to substrate and elongation of 200%. It has very good impact strength and withstands extreme temperature. ZC-ROOF GFM :ZC-ROOF GFM (Glass fibre matt ) is supplied by Owens Corning India Ltd. and it is made of glass fibre chopped strands. It is incorporated in this system because if the treated surface has foot traffic then plastic coating alone may not withstand the ware and tare. On the surface where no foot traffic incurs the ZC-ROOF GFM need not be applied. However it is strongly recommended to use ZC-ROOF GFM for long lasting effectiveness and toughness. ZC-Elastofalt : ZC-Elastofalt is a thixotropic cold applied polymer modified bituminous coating. It has very high adhesion strength. It protects the surface from water & weathering effects. The elongation is 900% and forms very good film on the substrate. It can be applied on any surface except ceramic tiles & metal. ZC-Elastoprime:ZC- Elastoprime is a primer or bond coat for surfaces like tiles or china mosaic chips. ZC-Elastofalt or ZC-Sealcoat do not easily adhere to the substrate like tiles or china mosaic chips. On such substrate it is essential to give bond coat of ZC-Elastoprime, which is actually ZC-Elastofalt diluted with water in the ratio 1:1. Surface Preparation Surface should be clean & dry. All the surface lying water, mould growths, moss or other vegetation, loose debris etc. should be removed prior to application. Ensure that surface is free from visible dampness, dust. Dirt and other form of contamination should be removed prior to application. Advantages Single component, multiplayer, solvent free Can be applied to different type of substrate No strong odour or toxic fume Fast curing & drying High tensile & elongation strength Permanently elastomeric and ageing proof Application by brush/roller/spray Absorbs rainfall sound Benefits Ready to use, simple application Long lasting realiability Does not crack or brittle UV/Heat resistance Crack bridging capability Traffic resistance Resistance to algae growth Reduces sound transmission

Best Deals from Waterproof Roof Coatings

Waterproof Coating For Rcc Roofs

Get Price Quote

Perma Weather ShieldINSULATION CUM WATERPROOF COATINGDESCRIPTIONPerma Weather Shield is an acrylic coating, which provides weather proofing and heat insulation to the exposed roofs. The product is in white paste form. Perma Weather Shield is based on acrylic binder and high quality non-conducting insulating fillers. Weather Shield when applied on roofs it reduces the heat transfer to the interiors thereby reducing the load on air conditioning system.PRIMARY USESPerma weather shield is especially developed for coating RCC roofs. It is also ideal for coating asbestos cements roofing sheets, galvanized zinc sheet as well as Aluminium Sheets. Weather shield where brush applied on any roofing system forms a thick reflective and non-conducting barrier for the sunlight in summers Its insulation value is highly beneficial in keeping the interiors cooler. In rainy season this acts as a waterproofing barrier.DIRECTIONS FOR USE Clean the area to remove all loose particles oil, grease and any such deleterious materials. If the surface is very rough make it even using polymer modified mortar or repair plaster. If the surface is very dry prime it with Perma Weather Shield diluted with water in the proportion of 1 volume of Weather Shield to 2 volumes of water. Brush apply Perma Weather Shield in one coat. In demanding situations Weather Shield can be applied in 2 coats. It may be noted that Weather Shield is a final coat on the roofing system. Any effort to apply another coating on weather Shield may make the insulation ineffective. Take only the quantity which is required for coating and keep the lid of the container closed. Perma Weather Shield functions on special insulation ingredient for its heat insulation and refractory properties. The materials, which constitute main insulation media, have a mean diameter of 120 microns. They withstand temperatures between 1600° C to 1800° C before melting and have compressins strengths of about 700 kg/cm2. These ingredients form a natural barrier against direct heat. Thermal Insulation of Roofs:Perma Weather Shield has a tendency to reflect back up to 85% of sun’s heat resulting in a cooler Interior. A comparison of two galvanized iron roofs, one coated with Perma Weather Shield shows a difference in temperature of about 10° C during hottest part of the summer. Further as a measure of percentage the difference shall be to the extent of 10 to 12 percent during peak summer.COVERAGE1 kg of Weather Shield covers an area of 30 to 35 Sq.ft/Coat, depending upon surface conditions.PACKINGPerma Weather Shield is available in 500 gms, 1 kg, 10 kg and 50 kg pack.SHELF LIFEPerma Weather Shield has a shelf life of 24 months if stored in Manufacturer’s original packing in a cool and dry place away from moisture and heat

AWC-Roof 300

Get Price Quote

PRODUCT COMPOSITION: AWC-ROOF 300 is a water based system, with high solids, elastomeric coating utilizing the advanced acrylic technology. Premium quality acrylic resins are combined with reinforcing laminar pigments & incorporating an epoxy additive to increase the abrasion resistance properties of the film. It has Special spherical silica sand suspended in the emulsion to provide a fine uniform texture. The silica can be eliminated for projects requiring fine smooth surface. AWC-ROOF 300 has two variants one is for exposed application & the other one for covered application. HOW IT WORKS: AWC-ROOF 300 provides a durable colored topping for horizontal concrete and asphalt surfaces. Its main highlight is its satin sheen finish which gives the surface a very aesthetic & attractive look. With the aesthetic look advantage, the product also works as a weather resistant. It can be applied on any kind of vertical surfaces such as building exteriors, highway bridge structures, median barriers, retaining walls and noise abatement walls. HIGHLIGHTS Water based system for easy application and cleanup Bonds tenaciously to concrete, masonry, stucco and asphalt surfaces Resists ultraviolet degradation for long term protection and color stability Provides durable, non-skid texture on interior or exterior surfaces Resists wear and abrasion through the incorporation of an epoxy additive Protects against asphalt degradation by sealing in the vital oils of the asphalt mix Helps prevent dusting and spalling of concrete surfaces Surfaces resist penetration from general soils, motor oils and gasoline for ease in cleaning No toxic fumes or objectionable odor. Meets all VOC requirements Technical Data Sheet Technical Data for AWC-Roof 300 MSDS for AWC-Roof 300 AWC-Roof 300 trifold