Weigh Feeder

Get Price Quote

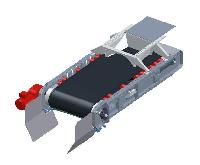

Principle of OperationA weigh belt feeder enables a continuous, controlled product flow. The bulk material is transported over a weighing section, placed in the feeder frame. The federate is calculated and the speed of the belt adjusted to maintain a constant feed rate.If the purpose of the belt feeder is to register the throughput only, the speed of the belt remains constant and the mass flow and cumulative weight is registered.ApplicationsWeigh Feeders are widely used in Coal feeding Steel plant Cement plant Chemicals & fertilizers Open mines Tobacco industry

Weigh Feeder

Get Price Quote

Best Deals from Weigh Feeder

Screw Type Weigh Feeder

202,000 Per Units

Weigh Feeder

Get Price Quote

We are offering weigh feeder applications in cement, steel, fertliser, chemical, pharmaceutical, food, refractories, ceramic, zinc, alum industries. Capacity 10 kghour to 500 tonneshour accuracy 0.5 % or better depending upon material characteristics. Micro controller based systems ensures highest possible reliability. Large size ( 8 mm) backlit lcd display for parameter values. Access to program mode through pass word. 4-20 ma signal proportional to flow rate is available. Rs232485 serial communication.

Weigh Belt Feeder

Get Price Quote

LIW feeder is a system to extract the granulated or powdered solids at constant rate from feed hopper; weight measured decrease in hopper content actuates further opening of the discharge chute to compensate for flow loss. The proposed system includes weigh hopper, Loadcells, screw conveyor with motor and microprocessor based control unit. This system is mostly used in chemical, fertilizer and plastics industries.

Weigh Belt Feeder

Get Price Quote

Smart Weigh Belt Feeder

Get Price Quote

weigh belt feeders for gravimetric feeding at higher feed rates or where low headroom is a problem. Especially at high feed rates, a weigh belt feeder offers lower initial cost than a loss-in-weight feeder with equal throughput.

Weigh Feeder

Get Price Quote

We are a top-notch Manufacturer, Exporter and Supplier of Weigh Feeder from Maharashtra, India. We are backed by a team of sincere personnel who makes use of non-corrosive and durable metal for its production so as to lift up its quality and performance. It is designed strictly keeping in mind the industry specified norms. You can get the Weigh Feeder from us at the cost-effective prices. Salient Features :Design : Very Sturdy and Rugged Frame Design Quick Belt change mechanism ensures very low down time. Designed for capacities from 1 to 2000 TPH Unique Dual Load cell design for accurate weighing Feed control inputs from Driving as well as Driven pulleys to ensure Precise feed rate. Accuracy as high as + 0.5% on the set point Electronics Our Electronic controller ensures trouble free interface with the plants processes and control system. Specially developed Software offers seamless integration with PLC or PC Service Support of the customer does not end once the equipment is sold. It is the beginning. With after-sales support being the cornerstone of our business philosophy, we offer prompt and efficient after sales service.

Weigh Feeder

Get Price Quote

Weigh Feeder, Belt Weigher, SCREW FEEDER

Weigh Feeder

Get Price Quote

Weigh Feeder, Check Weigher, Tank Weighing System

Thayer Weigh Belt Feeders

Get Price Quote

Thayer Weigh Belt Feeders, Ash Handling Dry Fog System

Weigh Feeder

Get Price Quote

Weigh Feeder, vertical form fill seal

belt weigh feeder

Get Price Quote

belt weigh feeder, Cement Plant Machinery

Weigh Feeder

Get Price Quote

Weigh Feeder, belt weighers, batching systems, Bagging Machine

Weigh Feeder

Get Price Quote

Weigh Feeder, net bagging machine, Electrostatic Precipitator