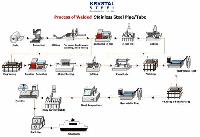

Welded Stainless Steel Tubes

Get Price Quote

We have positioned ourselves as a renowned name in the industry. We efficiently bring forth Welded Stainless Steel Tubes that are known for sturdy design, smooth finish, usage & maintenance and durability. The offered range of Welded Stainless Steel Tubes is as per the international quality standards. Details : Range includes metal products, industrial metal products and standard metal products. Heat Treated Hard Drawn Stress Relieved Bright Annealed Specifications : Outer Diameter - 3.00 mm - 76.20 mm Wall Thickness - 0.40 mm - 3.00 mm Length - Up to 30 meters U' Tube - Radius 1.1 D to 1 meter Tubes can be supplied in 600 feet for Diameter below 12.70 mm in coil form Standards : ASTM A-213, A-249, A-268, A-269, A-270, A-312, A-789, EN10216-5 and EN10217-7

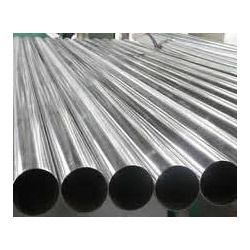

Stainless Steel Welded Tubes Ss 316 /316l Tube

Get Price Quote

we are offering stainless steel welded tubes ss 316 316l tube. these stainless steel welded tubes are made from fine quality of raw material which ensure durability at its user end. these stainless steel tubes are appreciated by large number of clients. these products are available in market at economical rates.

Best Deals from Welded Tubes

Stainless Steel Welded Tube

Get Price Quote

2 Metric Ton (MOQ)

Welded Tubes

Get Price Quote

we are a Renowned Manufacturer, Supplier, Exporter and Importer of Supreme Quality welded Tubes. Welded Tubes Offered By Us are Famous for Their Features like Rust Proof, Easy to Install, Dimensional Accuracy and Durability. all the Welded Tubes are Thoroughly Checked By Our Team of Quality Analyst So as to Provide Our Customers Defect Free Products. Welded Tubes are Widely Used in Various Applications Where Great Strength is Highly Required. features : rust Proofdimensional Accuracygreat Strengthcompetitive Prices

Welded Pipes Tubes

Get Price Quote

our existing clients of Welded Pipes, Seamless Pipe,Tube & tubing in India,UAE,Saudi Arabia,South Africa,USA (United States Of America),Malaysia,Singapore,Indonesia,Vietnam,Sri Lanka,Kuwait,Egypt,Netherland,Maxico,Italy any many more countries around the world call us that you are our Welded Pipes, Seamless PIPE & TUBING PROFESSIONALS, most of our clients says that we got the material in time, whenever we had urgent requirements of specific grades in Welded Pipes, Seamless Pipe,Tube & Tubing,

Electro Welded Tube

Get Price Quote

We are offering electro welded tube.

ss welded tubes

Get Price Quote

We are the leading manufacturers, exporters and supplier of this products.

Welded Steel Tubes

Get Price Quote

We bring forth a wide range of Welded Steel Tubes that are highly appreciated for their dimensional accuracy, high tensile strength, corrosion resistant features, and easy installation. The Welded Steel Tubes is sourced from reputed vendors and are provided to the clients at market leading rates. Form : RoundSquareRectangleOvalCoilFlexible PipeShaft'U' Shape Length : Standard length & In Cut length also Size : 6.35 mm OD to 152 mm OD Sch. & Swg : 20 Swg., 18 Swg.,16 Swg., 14 Swg., 12 Swg., 10 Swg Grades : Stainless Steel : TP 304, 304H, 304L, 304LN, 316, 316H, 316L, 316LN, 316Ti, 309, 310, 317L, 321, 347, 409, 410, 420, 430, 446, 202 Etc.Cupro Nickel : 9010, 7030, 663022Hastelloy : C-4, C-22, C276, B-2Nickel : 200 201 205Monel : 400 & K500Inconel : 600, 601, 625 & 825Incolloy : 800, 800HAlloy 20, Duplex Steel, SS 904L, Etc

Titanium Welded Tube

1,400 Per Kilogram

Welded Steel Tubes

210 Per Kilogram

Deplux Electro Welded Tube

Get Price Quote

Seamless Welded Pipes Tubes

Get Price Quote

ALLOY 200 SEAMLESS PIPE Alloy 200 nickel pipe is made from commercially pure wrought nickel, with good mechanical properties, excellent resistance to many corrosives. Typical applications include a variety of processing equipment, particularly to maintain product purity in handling foods, synthetic fibers, and alkalies. Stock Size Range: OD: 1/2" through 6" Wall: .Schedule 10 through Schedule 80 Specifications: ASTM B 161, ASME SB161 Nickel 200 and Nickel 201 are solid solution strengthened, commercially pure wrought materials with good mechanical properties over a wide range of temperatures and excellent resistance to many corrosives, in particular hydroxides. Nickel 201 was a modification of 200 to control carbon (.02 max) which keeps it from being embrittled by intergranular precipitates at temperatures of 600° F to 1400° F in many processes. Typically, the elemental restrictions of both, nickel 200 and nickel 201, are combined into one, dual-certified chemistry resulting in a single alloy with the desired characteristics of both alloys, Nickel 200/201. In what forms is Nickel 200/201 available at K.M Steel? Sheet Plate Bar Pipe & Tube (welded & seamless) Fittings (i.e. flanges, slip-ons, blinds, weld-necks, lapjoints, long welding necks, socket welds, elbows, tees, stub-ends, returns, caps, crosses, reducers, and pipe nipples) Wire What are the characteristics of Nickel 200/201? Highly resistant to various reducing chemicals Excellent resistance to caustic alkalies High electrical conductivity Excellent corrosion resistance to distilled and natural waters Resistance to neutral and alkaline salt solutions Excellent resistance to dry fluorine Widely used to handle caustic soda Good thermal, electrical and magnetostrictive properties Offers some resistance to hydrochloric and sulfuric acids at modest temperatures and concentrations Both Nickel 200 and 201 offer corrosion resistance in reducing and neutral media as well as in oxidizing atmospheres provided that the oxidizing media allows the formation of a passive oxide film. This oxide film accounts for the materials excellent resistance in caustic environments. Corrosion rates in both marine and rural atmospheres are very low. The resistance of Nickel 200/201 to corrosion by distilled and natural waters is excellent. Plus it also gives excellent service in flowing sea water even at high velocity, but in stagnant or very low-velocity sea water severe local attack may occur under fouling organisms or other deposits. In hot water systems where the steam contains carbon dioxide and air in certain proportions, corrosion rates will be initially high but will decrease with time if conditions favor the formation of a protective film. Nickel 200 is normally limited to service at temperatures below 600° F. At higher temperatures Nickel 200 products can suffer from graphitization which can result in severely compromised properties. When operating temperatures are expected to exceed 600° F, carbon content becomes critical. The lower carbon content of Nickel 201 makes the material resistant to graphitization and therefore less subject to embrittlement. Nickel 200 & 201 are approved for construction of pressure vessels and components under ASME Boiler and Pressure Vessel Code Section VIII, Division 1. Nickel 200 is approved for service up to 600° F while Nickel 201 is approved for service up to 1230° F. Melting point is 2615-2635° F.

Welded Steel Tubes

Get Price Quote

Stainless Steel Welded Tubes

Get Price Quote

We are a leading name in the arena of manufacturing and exporting of a wide range of Stainless Steel Welded Tubes available in various standards of stainless steel as per client's specific requirements.

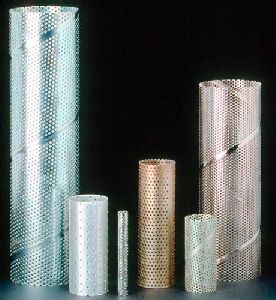

Welded Perforated Tubes

Get Price Quote

Welded Tubes

Get Price Quote

Hitesh Steel is one of the reputed manufacturers and exporters of Welded Tubes, which are, designed by the diligent engineers. Our Welded Tubes are appreciated in global markets for their high tensile strength, corrosion resistant nature, easy installation, low maintenance, etc. Attributes : Dimensional accuracy High tensile strength Corrosion resistant features Easy installation Great strength Durable Fine finish Applications : Energy industry Desalination industry Food industry Oil & gas industry Chemical industry Metallurgical industry Pulp & paper industry Ships industry Range : 1 mm OD upto 254 mm OD in 0.2 TO 20 mm thickness. Availability : Nickel Alloy : Standard : ASTM / ASME SB 163 / 165 / 167 / 464/ 517 / 619 / 622 / 626 / 704 / 705. Grade : UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8020 (ALLOY 20 / 20 CB 3) UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600) UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276) Copper Alloy Tubes : Copper Tube Electrolytic / Dioxide Copper Nickel : ASTM / ASME SB 111 UNS NO. C 70600 ( CU -NI-90/10) / C 71500 ( CU -NI- 70/30) / C 71640 ( CU-NI-66/30/2/2) Admiralty Brass : ASTM / ASME SB 111 UNS NO. C 44300 ( ALLOY 443) Aluminium Brass : ASTM / ASME SB 111 UNS NO. C 68700 ( ALLOY 687) Stainless Steel Tubes : Standard : ASTM / ASME A/SA 269 / 213 / 249 Grade : 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L. Carbon Steel Tubes : ASTM / SA 179 / A 210 GR.A / BS 3059 GR.360 & 440 Alloy Steel Tubes : Standard : ASTM / ASME A/SA 213 Grade : T9, T11, T12, T22, T9 Form : Round Square Rectangular Coil 'U' Shap Length : Single Random Double Random Cut Length End : Plain End Bevelled End Treaded Variants : Hydraulic Tube Horn Tube Capillary Tube Boiler Tube Precision Tube IBR Tube

304H Stainless S

180 Per Kilometer

304H Stainless Steel ERW Welded Tube

Stainless Steel Welded Tubes

225 Per Kilogram

1000 Kilogram (MOQ)

Stainless Steel Welded Tubes

120 - 350 Per Kilogram

50 Kilogram (MOQ)

Welded Alloy 20 Tube

Get Price Quote