Welding Machine

Get Price Quote

We, Sparkweld Engineering, Mumbai, are manufacturer and supplier of world class Utensil Stud Welder (Pan Welding Machine). With the diverse application in its portfolio, Pan Welding Machine serves the variety of kitchenware manufacturer in India. The main feature is excellent aesthetic in welding. Pan Welding Machine serves simple as well as a complex application so won the trust of kitchenware manufacturer as they want the latest technology to create best and innovative products. Our specialized Pan Welding Machine efficiently serve the vast diversity of kitchenware which is key to growth and profitability of every manufacturer. Features: Excellent aesthetic in welding. Fully pneumatic control and pneumatic lift facility. Easily adjustable height. Robust and lightweight. Aluminium construction to restrict magnetic influence. Different angle adjustment on welding head and pan bolster for angled welder fixings. Adjustable air control and interchangeable bolster arrangement. For the correct stud position on pan wall, linear movement of the front plate is provided. Specifications: Brand: Sparkweld Engineers. Product Code: SE-06. Type: Stored Energy Discharge. Welding Head Operation: Pneumatic. Welding Head: Initial Contact Type. Stud Range: Up to 10mm square aluminium. Base Material:1.2mm and above. Gas: Argon 99%. Input Supply Voltage: 240v,A.C.,10Amp. Charging Voltage:60 to 180 volts, D.C., Stepless.

Mig Mag Welding Machines

Get Price Quote

IGBT Based Inverter Controlled MIG MAG Welding Equipments, Machine Model: ENDEAVOUR 250 400 600 (MIG MAG Welding Equipments)Excellent Arc characteristic over entire range, Stepless Voltage Selection, Excellent Portability and Mobility

Best Deals from Welding Machinery

Welding Rods

Get Price Quote

Product Features: 1. Excellent chemical and corrosion resistance. 2. Excellent flame retardant. 3. Excellent durability. 4. Reliable electrical insulation. 5. Excellent formability. 6. Good welding performance. Applications: PCB equipments. Semiconductor processing equipments. Chemical tanks. Pharmaceutical. Construction. Range: 1mm to 250mm. Color: White/Black/Grey/Customized Grades: PVC/PP/PVDF/HDPE/CPVC Standard Size (Kgs):3 Kgs Coils & Straight Form Versions: High Chemical & High Temperature resistant grade/customized shapes

Gas Brazing & Soldering Machine

Get Price Quote

Specially suitable for brazing in goldsmithing applications like Jewellery ,Eyewear ,Dentistry & glass processing

mag co2 welding machine

Get Price Quote

Gas Metal Arc Welding (GMAW), sometimes referred to by its subtypes Metal Inert Gas (MIG) Welding or Metal Active Gas(MAG) Welding, is a Welding process in which an electric arc is formed between a consumable wire electrode and the work piece metal, which heats the work piece metal, causing them to melt and join. Along with the wire electrode, a shielding gas is fed through the welding gun, which shields the process from the contaminants in the air. The process can be semi-automatic or automatic. A constant voltage, direct current, power source is most commonly used with GMAW, but constant current systems as well as alternating current can be used.

Laser Welder

Get Price Quote

Features stereo zoom microscope leica 100 programmable memories backlit display command external touch screen display dispenser of inert gas can be positioned the welding point internal control joystick integrated cooling system our laser welding integrates an innovative digital system management functions fdc called "full digital control." with this system, the new generators become 5 times more stable than an ordinary generator, supplying power stable over time because continuously monitored and automatically adjusted in real time. The shutter has a luminosià doubled and the frequency of firing reaches 40 hz. The new generator is able to independently asses the state of wear of the laser light and automatically adjust the energy produced according to user settings, without having to change over time. Our laser welders are also suitable for high production runs thanks to the new and very efficient cooling system of the laser light, and the innovative digital power supply very low heat. applications welding of metals including precious and non –silver, gold, chrome cobalt, titanium , stainless. Welding of elements through the use of filler materials, leaving the affected area clear, shiny without the need to intervene with the procedures of polishing. Repair of casting defects such as porosity or fractures of the unwanted metal, welding flaw with the weld material the large working chamber and the ease of access to the same allows welding also details of a considerable encumbrance

Butt Welding Machine

Get Price Quote

BUNCHED STANDING CONDUCTOR CAN BE WELDED WITH THE HELP OF CERAMIC TUBE WITH THIS MACHINE. Useful to run the wire on Automatic Machine under tension

Inverter Welding machines

Get Price Quote

Inverter technology is a voltage conversion system which applied to welding makes compact power sources with low energy consumption. Inverter based constant direct current power sources use the latest knowledge of Electronics technology applied to welding. Totally Indigenous Inverter welding machine using IGBT technology, suitable for Indian working condition (TEMP, HUMIDITY, DUST & VOLTAGE FLUCTUATIONS)

Plasma Welding Machine

Get Price Quote

Plasma Welding Machine is IGBT based inverter power supply which saves power consumption. Manufactured in advanced inverter design system which delivers continuously adjustable constant current output. provides you stable arc at as low as 0.5 Amps. High open circuit voltage for best arc striking and for best quality welding. Electronic pilot arc system gives soft start and reliable arc striking. Power consumption is very low below 0.1 V & no load. Stepless setting for pilot arc & main arc current. current setting features available for Local or remote arc . Front panel digital display show the actual welding current as well as pilot arc current.

Oil Cooled Welding Machine

Get Price Quote

POWER FACTORS CAPACITORS: Often the electric supply authority is particular about power factor of equipments installed in their area. As transformer type welding machines have inherently low power factor, the use of power capacitor is recommended. Suggested size is mentioned with specification and will be supplied at extra cost if desired.

Steel Grating Welding Machine

Get Price Quote

Steel grating welding machine this machines work of Grating, informative Grating, this product was good Steel grating welding machines.

Wire Butt Welding Machine

196,000 Per Piece

1 Piece (MOQ)

Arc Welding Transformer Machine

20,000 Per Piece

1 Piece(s) (MOQ)

vibration welding machine

2,500,000 Per Piece

Stainless Steel TIG Welding Filler Rod

400 Per Kilogram

Vibrating Screen

Get Price Quote

Features Long flowing line many screening specifications Strong violent vibrating force High screening efficiency Small vibrating noises Firm and durable construction Convenient maintenance and safe operation Description The vibrating screen is a kind of sieving equipment of international advanced level, developed by our company on the basis of carrying on the advantages of traditional screens and absorbing the outstanding technology from abroad. Now they are installed in about 130 countries of the global market. Application Vibrating Screen is widely used for grading and screening materials in the following fields: minerals, quarry, building materials, water conservancy and hydropower, transportation, chemical industry, smelting and so on. For material quality of screen mesh is changeable, the application is quite extensive.

Thermocouple Welder

Get Price Quote

gas torch

Get Price Quote

Plasma Welding Machine

Get Price Quote

Plasma Welding Machine, Plasma Cutting Machine, inverter welding machine

Welding Rotators

Get Price Quote

Welding Positioners, Submerged Arc Welding Machine

Laser Spot Welding Machine

Get Price Quote

We are offering laser spot welding machine. versatility of modulating power and speed in a nicer looking cabinet and improved reliability with added features: color touch-screen display for an easier access to working parameter and better machine-to-operator interfacing/messaging fully displaying basic working parameters power, time, frequency of repetition, spot size; and by the joystick inside the welding chamber memory cells to record permanent working settings for later use preset pulse-shaping programs for laser-welding alloys with special metallurgic characteristics halogen light adjustable by dimmer argon-gas supplied coaxially to the laser-beam over targeted object large integrated sealed circuit for cooling the flash-lamp specifically devised for longer laser-welding sessions by experience, the flash-lamp will last for at least 5 million pulses thanks to its reduced size and weight, this unit is easy transportable applications of clw – 100dt/ 60dt weld precious metals easily, including platinum, titanium, gold, silver & palladium repair perfect antique jewelry repair the frames without having to remove the stones repair watches & other components, even the glasses weld filler materials using the elements & lets you clear , crisp & with no need to clean up repair fusion defects such as porosity or fractures, only in those areas of the welding filler wire

Welding Electrodes

Get Price Quote

Welding electrodes are used to fuse two pieces together and is available in consumable or non-consumable finish. These electrodes find usage in providing current using nonmetal objects for altering them in different ways so as to measure conductivity for different purposes. Some end usages these are used in include for medical purposes, for electroplating, arc welding, grounding as well as for chemical analysis using electrochemical methods. The range offered by us under this includes mild steel electrodes, low hydrogen type, low alloy high tensile, stainless steel electrodes, hard facing, casting, cutting & gouging and maintenance electrode.

welding mirror

Get Price Quote

HDPE Pipes which is available as per IS 4984 : 1995. The HDPE Pipes are available in various sizes from 20mm OD to 630mm OD in all pressure ratings. These HDPE Pipes are available in PE-63, PE-80, PE-100 Grades.

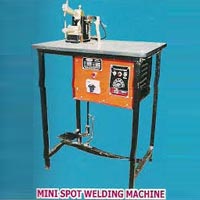

Spot Welding Machine

Get Price Quote

We are renowned Manufacturer, Supplier and Exporter of Spot Welding Machine in Maharashtra, India. Robust construction, high performance, corrosion resistant parts are the highlights of our Spot Welding Machine. In addition, it is wear and tear resistant too. Buyers are free to place bulk order and we make sure that it is duly delivered. We are well equipped with in-house testing lab for quality assurance where the product is stringently tested many a times. Moreover, we offer the Welding Machine at market-leading prices.

Spot Welder

Get Price Quote

Spot Welder, Dc Drive, electronic vibrator controller, Welding Transformer

Friction Welding Machine

Get Price Quote

Friction Welding Machine, Bimetallic Lugs

Semi Automatic Automatic Welders

Get Price Quote

Tig welding rods

Get Price Quote

Tig welding rods, NovaTherm ABS Sheets, NovaRene HIPS Sheets

Butt Welding Machine

Get Price Quote

BUNCHED STANDING CONDUCTOR CAN BE WELDED WITH THE HELP OF CERAMIC TUBE WITH THIS MACHINE. Useful to run the wire on Automatic Machine under tension

Head Protection

Get Price Quote

HSE Integro offers a wide range of head protection in the form of safety helmets , hard hats and its related accessories.