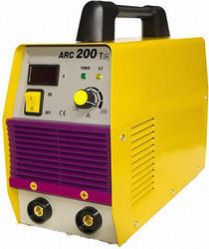

Arc Welding Machine

Get Price Quote

Creating a niche of Arc Welding Machine such as Arc 200, Arc 250, Arc 300, Arc 400 MOS and Heavy Duty Welding Machine at its best, with utmost quality. Features: Smooth Edges Easy to maintain Better Performance

Heat Welding Gun

Get Price Quote

We are the leading supplier of this products.

Best Deals from Welding Machinery

Saddle Welding Machine

Get Price Quote

Saddle welding machine is suitable for welding branch pipes on the large size pipes. With replacement of different core molds, assembly of pipes of different specifications can be achieved.

mag co2 welding machine

Get Price Quote

Gas Metal Arc Welding (GMAW), sometimes referred to by its subtypes Metal Inert Gas (MIG) Welding or Metal Active Gas(MAG) Welding, is a Welding process in which an electric arc is formed between a consumable wire electrode and the work piece metal, which heats the work piece metal, causing them to melt and join. Along with the wire electrode, a shielding gas is fed through the welding gun, which shields the process from the contaminants in the air. The process can be semi-automatic or automatic. A constant voltage, direct current, power source is most commonly used with GMAW, but constant current systems as well as alternating current can be used.

Gas Brazing & Soldering Machine

Get Price Quote

Specially suitable for brazing in goldsmithing applications like Jewellery ,Eyewear ,Dentistry & glass processing

Arc Welding Machine

Get Price Quote

INVERTEC 400 A Name the task…..heavy machinery, trucks or trailers, locomotives, Tank and pressure vessels, structural steel work, sheet metal fabrication, machine is ready to provide you with exceptional value and return on your investment Construction. Chemical process plants. Die and mould repair. Defense equipment. Foundries of refineries. Food processing equipment fabrication repair. For shop & field welding where an extremely smooth welding arc is required. High out put range for burning grooves, slots. Nuclear power plants. “On-the-job” welding when access to work is difficult. Off-Shore, platforms structural. Positional pipe welding where welds of high radiographic soundless arc required. Rail, Road, Ship building industry. S.S. tube Mills. Thermal power plants mining equipment. Weld carbon low alloy and stainless steel, also for hard facing. X-ray quality weld can be achieved.

Semi Automatic Automatic Welders

Get Price Quote

Head Protection

Get Price Quote

It’s important to maintain your workers secure and efficient. the primary manner to do this is to ensure that they put on halmets and other safety equipments all day lengthy. Users will not wear hats that are uncomfortable or fit poorly, resulting in constant removal and readjustment.

Welding Fume Extractors

Get Price Quote

Our grinding / welding fume extractors are perfectly suited to remove various residues released during grinding or stone cutting process. Grinding / Welding fume extractor is built to be used in all those cases which executes processing of dry grinding, sharpening tools with emery grinding wheel where there is a possibility to convey incandescent particles with the air that might damage the filters. The overall size of the system is very small and produces very low noise. The aspirated air can be recalculated in to the working environment thus saving energy and the running costs can be reduced through the implementation of high yield fans. The filter used in this system can be cleaned manual by easily removing the filter unit with simple use of service wrenches. Due to the preliminary water system any spark present in the air is extinguished before it comes in contact with the filters. This prevents the danger of fabric damage as avoids fire hazard

mig torch

Get Price Quote

TBi Industries is the world leader for the manufacturing of different types of Welding Torches such as MigMag, Tig, FCAW(Open Arc ), Semi-Automatic, Automatic, Robotic etc for Shipyards, Sheet metals , Fabrication and Automotive Industries.A complete range of compact push-pull torches, intermediate wire drives and drive boxes for robotic applications is available. Development of Tandem (Twin-wire) welding torches with a new cooling system.

Wire Feeder Machine

Get Price Quote

The Minex History of Wire Feeder is over 30 years, in the field of Steel & foundry industries. Over 400 installations have been commissioned during these years from the smallest for below 1 MT Ladle to extra-large one with Four Strand capability. Minex has installed over 90% of the Wire Feeder facilities in this country and many of them are repeat orders, project start-ups along with metallurgical support. Minex expertise in cored wire and injection systems enables us to offer complete turnkey solutions for cored wire technology implementation.

Stainless Steel TIG Welding Filler Rod

400 Per Kilogram

Butt Welding Machine

Get Price Quote

BUNCHED STANDING CONDUCTOR CAN BE WELDED WITH THE HELP OF CERAMIC TUBE WITH THIS MACHINE. Useful to run the wire on Automatic Machine under tension

Laser Welding Machines

Get Price Quote

Laser Welding Machines, Laser Marking Machine, Laser, Laser Marking

inverter based arc welding machine

Get Price Quote

inverter based arc welding machine, Spot Welding Machine

Welding Electrodes

Get Price Quote

Welding Electrodes

CO2 MIG Welding Wire

Get Price Quote

CO2 MIG Welding Wire, zirconium wire, Ptfe multicore wires

Anti Spatter Spray

Get Price Quote

Anti Spatter Spray, nozzle gel, ss filler wires

welding machine parts

Get Price Quote

welding machine parts, Welding Machines

Pipe Welding Machine

Get Price Quote

Pipe Welding Machine, Hydraulic welding machine