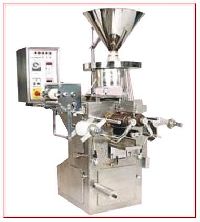

Strip Packing Machines

Get Price Quote

Semi Automatic Strip Packing Machine is extensively used to pack tablets, capsules, caplets, coated tablets, soft gelatin capsules. The same is also used to pack supari, , refills, battery cells, mats, bearings, oil seals, steel balls, chewing gum, toffees etc

wire drawing tools

500 Per Piece

1 Piece(s) (MOQ)

Best Deals from Wire Machinery

Strip Packing Machine

Get Price Quote

We are offering strip packing machine. Packs a wide range of products in easily dispensable strips with economy and speed. With capacity up to 2400 strips per minute, its automatic trouble free operation meets exacting marketing market standards. For pharmaceuticals, coated and uncoated tablets, hard gelatin capsules, capsule, shape coated and uncoated tablets, confectionary products like lozenges, toffees and chewing gum, plastic, rubber and engineering products, buttons, pins, electronic components.

Wire Stitching Machine

Get Price Quote

The length of book, no. of stitches and distance between stitches is to be saved once in 20 programs memory. Upto 12 stitches in one book can be achieved in this unique machine by Deluxe M30 stitcher head with superb quality stitch and long life. M30-STITCHmaster can be online attached to STALLION FOLDmaster : Book Folding Machine or STALLION TAPEmaster : Auotomatic Spine Taping Machine, Minimum distance between two stitches.

Strip Packing Machine

Get Price Quote

The integrity of seal is very high and offers good protection to packaged products thus improving shelf life. Strip packing machine is a double web laminated foil packing machine.

Semi Automatic Wire Drawing Tools

500 Per Piece

1 Piece(s) (MOQ)

wire mesh welding machine

Get Price Quote

18 Ltr Stripping Machine

Get Price Quote

1 Piece (MOQ)

Semi Automatic Wire Stitching Machine

260,000 Per unit

strip machine

Get Price Quote

Packs a wide range of products in easily dispensable strips with economy and speed. With capacity up to 2400Strips per minute, its automatic trouble free operation meets the market standards.Capable of handle wide range for pharmaceuticals products namely, Coated and Uncoated tables, Hard gelatin capsules, Capsule shape Coated and Uncoated tablets, standard confectionary products etc.

Wire Cleaning Machine

Get Price Quote

Requests for cleaning processes in the wire industry are continuously increasing and at the same time with increased quality requirements. Cleaning is the removal of contaminants present on the surface of the wire but not.chemically.linked.to.it. Cleaning is used for stainless steel, low and high carbon steel, aluminum alloy, copper wire to remove calcium and sodium parts lubricant residues after the dry drawing process, or lubricant oil from a wet drawing machine or forming process etc. Two types of technologies are usually proposed for this purpose: ultrasonic cleaning and electrolytic cleaning. Both of them have advantages and have to be chosen carefully depending on the type of wire and the type of products to be removed from the wire. Let’s compare briefly the two technologies. Ultrasonic cleaning is the use of high frequency sound waves. This results in cavitation, in which micro-size bubbles form, grow and implode due to alternating positive and negative pressure waves. Just prior to the bubble implosion, there is a tremendous amount of energy stored inside the bubble itself. The implosion event if it occurs near a hard surface changes the bubble into a jet which travels at a speed of approximately 400km/h towards the hard surface. Because of the inherent small size of the jet, ultrasonic cleaning has the ability to reach into small crevices.and.removed.entrapped.soils.very.effectively. The basic components of an ultrasonic cleaning system include some ultrasonic transducers, an electrical generator.and.a.tank.containing.the.cleaning.solution. The ultrasonic generator converts a standard electrical frequency of 50 or 60 Hz into the high frequencies required. The higher the frequency, the smaller the bubbles created during the cavitation will be. The transducers are constituted of PZT elements (Pb-Zr-Ti) which converts the electrical energy into mechanical vibrations by piezoelectric action. The transducers are installed inside a watertight box made in stainless steel immersed in the cleaning bath and located some centimeters below the wire field. A watertight cable connects the transducer holding box to the generator.The cleaning solutions used in the ultrasonic cleaning lines have to be chosen with care taking consideration of the type of wire and the application. Generally speaking for the majority of the applications in the wire industry, alkaline solutions are preferred to remove oily matter and phosphoric acid based solutions are preferred to remove stearate soaps. The working temperature has a profound effect on ultrasonic cleaning effectiveness. In general higher temperatures will result in higher cavitation intensity and better cleaning. However, if the solution temperature too closely approaches the boiling point of the solution, the liquid will boil in the negative pressure areas of the sound waves, reducing or eliminating the cavitation effect. We usually work around 60°C (140°F) which offers an excellent compromise. In the electrolytic process, the wire passes through an electrolyte in a processing zone divided into different chambers. Electrodes are located in each chamber and adjacent electrodes are connected to opposite poles of a direct current supply source. Electrical current is constantly passing between the electrodes in the adjacent chambers through the electrolyte and the wire while it is traveling through the chambers in the processing zone. In this way, the wire is alternately polarized negatively and positively as it travel through the processing zones. The migration of ions of the electrolyte as a result of the polarization will allow some chemical reactions to take place quickly at the surface of the wire like hydrogen or oxygen bubbles formation. Those bubbles created at the surface of the wire will remove by a mechanical effect the dirt present on the wire.

knitted wire mesh machine

Get Price Quote

Knitted wire mesh machine of the same diameter. Aluminum & Fiber glass are widely used in doors & windows for insect & mosquito prevention. Application of Mesh & Specification of Wire Composition like Mild Steel, Galvanised, Stainless Steel, Monel, Inconel, Titanium, Phosphorus Bronze, Silver & many more along with Diameter varies from Industry to Industry.

wire coating machine

1,500,000 Per Piece

wire enameling machines

4,000,000 Per Piece

1 Piece (MOQ)

Wire Wrapping Machine

Get Price Quote

The industry demands coil wrapping machine reliability and efficiency. Fhope meets this challenge by supplying durable, reliable and energy efficient coil wrapping equipment. This is backed up by a unique level of supply that provides our customers with the best wrapping solution both commercially and operationally.

Wire Stitching Machine

Get Price Quote

1 Piece (MOQ)

Strip Packing Machine

Get Price Quote

Packs a wide range of products in easily dispensable strips with economy and speed. With capacity up to 2400 strips per minute, its automatic trouble free operation meets exacting marketing market standards. Capable of handle wide range for pharmaceuticals products namely, coated and uncoated Tablets, Hard gelatin capsules, Capsule shape coated and uncoated tablets, standard confectionary products etc. Special Features: GMP construction. Models ranging from 2 tracks to 10 tracks, 40 mm to 300 mm sealing width. Take off conveyors of different sizes to convey strips to inspection and packing tablets. Customised to different product sizes and shapes. Machine suitable for different heat sealable packing laminates. Temperature control by thermostat or digital temp. indicator and control panel manpower for operation. Electrical motor suitable for 415 V/ 380 V/ 3 PH/ 50 CS/ AC Supply.

Multi Roller Wire Mounting Machine

800,000 Per Unit

1 Unit (MOQ)

Strip Packing Machines

Get Price Quote

Packs a wide range of products in easily dispensable strips with economy and speed. With capacity up to 2400Strips per minute, its automatic trouble free operation meets the market standards. Capable of handle wide range for pharmaceuticals products namely, Coated and Uncoated tables, Hard gelatin capsules, Capsule shape Coated and Uncoated tablets, standard confectionary products etc.

Fine Wire Drawing Machine

Get Price Quote

The machine can draw wire continuously from 1.5 to 0.3 mm as per the customers requirements, we can suggest medium fine wire drawing machines, with line speed of 40 meters second.

Wire Bending Machine

Get Price Quote

Saminder Singh Saan the son of Respected Mr Joginder Singh Saan is B.E.(HONS) in Mechanical Engg from London ,UK following the legacy of the family adding a new dimension to the organisation. Taking care of International Business and introducing the new concept of Machine Designing and manufacturing as per the European Standards. This machine produces cotton bail wire knots using striaghtened cut wires as raw material.

wire mesh welding machine

Get Price Quote

We provide the best quality of wire mesh welding machine, which is specifically designed to weld low carbon steel wire. In addition the finished product is used to make fence mesh. The wire mesh welding machine is known for its high speed, elevated performance, durability, and ease of use. Specifications of the product are mentioned below:

WIRE COILING MACHINE

20,000 Per Set

1 piece (MOQ)

WIRE COILING MACHINE, CNC Machined Parts, milling Machines

Wire-Cut Dropping Machine

Get Price Quote

Fully customized model of cookies, wire-cut dropping machine gives you quality production resulting in lower production & labour cost. Also this machine gives you flexibility for both large & small production requirements.

Swaging Machine

Get Price Quote

Wire Feeder Machine

Get Price Quote

The Minex History of Wire Feeder is over 30 years, in the field of Steel & foundry industries. Over 400 installations have been commissioned during these years from the smallest for below 1 MT Ladle to extra-large one with Four Strand capability. Minex has installed over 90% of the Wire Feeder facilities in this country and many of them are repeat orders, project start-ups along with metallurgical support. Minex expertise in cored wire and injection systems enables us to offer complete turnkey solutions for cored wire technology implementation.

WIRE BARBED MACHINE (AUTOMATIC)

Get Price Quote

Stripping Machine

Get Price Quote

Gold stripping Ideally from all Side Cyanide Free Used For 14KT / 18KT / 22 KT Ideal for Studded Jewellery Ideal for getting Equal weight

Gi Stitching Wire Plant

Get Price Quote

Gi Stitching Wire Plant, hand board cutter, Hydraulic Waste Pasting Machine

cnc wire cut machining

Get Price Quote

cnc wire cut machining, cnc programming, cad training services