Wire Drawing Machine

Get Price Quote

The VM/6P, VM10P and VM/12P models are multi-pass straight-line drawing machines designed to process ferrous, non-ferrous and noble wires, which are available in two versions: variable speed, adjusted via potentiometer, or 2 fixed speeds (VM/6P2, 10P2 and 12P2) In both cases the movement is ensured by a three-phase motor with alternating current transmission through reducer in oil bath and is able to guarantee a drawing speed of up to 80 m/min. Advantages: Transmission through reducer in oil bath Reel with electronic friction Very functional operator panel Optional electronic winding unit Strong, solid frame Very reliable Compliance with the required standards Explanations: The movement is ensured by a three-phase motor with alternating current transmission through reducer in oil bath and is able to guarantee a drawing speed of up to 110 m/min. The steel conical reel with hard chrome surface comes with a mechanical clutch with auto-leveling tempered discs for the constant tensioning of the wire and the smooth startup of the system; a closed-circuit cooling and lubrication device ensures the temperature dispersion of the die-holder group and the motorized conical reel during processing in order to delay wear and collect scrap materials. An easily accessible, highly functional control panel allows the operator to manage all operations in an immediate, streamlined fashion. Activations via foot pedal when the machine is both open and closed. The VM/6P, 10P and 12P drawings are equipped with optional electronic winding, and safety protection in accordance with internationally required standards.

Wire Flattening Machine

Get Price Quote

Wire Flattening Machine that we offer is energy efficient and has longer service life. The best thing about our Wire Flattening Machine is that it is portable. We are counted among the top Manufacturers, Exporters and Suppliers of Wire Flattening Machine. It is manufactured in compliance with the set industry standards and tested by our team of qualified quality controllers. Sturdy construction, noiseless operation and easy handling are some of the attributes that make our machine highly popular. Wire Flattening Machine that are highly efficient and reliable. Featuring robust designs, fine construction, portable size, low maintenance and energy efficiency these products showcase unmatched quality. All products are assured to be in compliance with the prescribed industry standards by our team of qualified quality controllers. Features: Sturdy construction Noiseless operation Easy handling

Best Deals from Wire Making Machines

Strip Forming Machine

Get Price Quote

Panchal Engineering Works is a renowned and trusted manufacturer of shutter strip forming machine in Mumbai. This machine of our company has a strong structure and great strength. We manufacture this machine using the latest technology and equipment and good quality materials under the supervision of our experts and professionals. You can easily operate our machines and it is safe for use. FeaturesVery Low Maintenance The products of our customers are low maintenance. You do not have to clean or check it’s parts regularly. It can work well even if you clean the machine once in a while. Our machines have a long life and can work without any trouble.Sturdy Construction We have manufactured our machines based on the parameters set by the industry. We check our products and make sure that it has a robust and sturdy design and structure.Cost-Effective Our machines are long-lasting and have a great functional life as mentioned earlier. We have listed our products at an affordable price and it needs little to no maintenance. This lasts long for years and it is worth your money. Therefore choose us and get our machines. We are the best strip forming machine supplier.

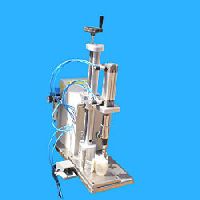

bottle crimping machine

Get Price Quote

Pneumatic Perfume Bottle Crimping Machine is a single head machine, which is the higher version of Hand operated Perfume Crimping Machine. This machine is most suitable for small, medium and lab purposes. Also, this machine is very much useful, where there is less human labour is available. Here, the operating strength of human hands for crimping is replaced by a pneumatic cylinder. So, ladies can also easily operate this machine for long time.

Tube Crimping Machine

Get Price Quote

Tube Crimping Machine for crimping of Aluminium & Collapsible Tubes with BNo, ExpDt, etc. embossing available. Speeds upto 30 tubes per minute is obtainable.

Jewellery Wire Drawing Machine Model AK-WDM6

Get Price Quote

We are engrossed in fabricating a felicitous range of high-quality Jewellery Wire Drawing Machine Model AK-WDM6 and offering it to various jewellery makers in a time-efficient manner. We are amongst the notable Manufacturers and Suppliers of Jewellery Wire Drawing Machines in Mumbai, Maharashtra. These machines are made of premium materials and are kept in line with the standards. They are appreciated for consuming low power and performing phenomenally throughout their span.

Wire Stitching Machine

Get Price Quote

Suitable for center and side stitching Run on single face motor Estimated life 25 years 2 Pages can be stitched All Spares available readily form ready stock Most dependable and reliable machine available in the market

Aerosol Crimping Machine

45,000 - 50,000 Per

1 Box (MOQ)

tube annealing machine

Get Price Quote

1 Set (MOQ)

We are offering this machine uses automatic temperature controlling techniques. Main features: 1. Four layers of heat preservation,efficiency and save energy. 2. Suspended type furnace chamber, rate of finished products is high. 3. Products’ annealing is balanced, the same hardness. 4. Automatic temperature control, temperature will be displayed automatically. annealing machine in order to make tubes reach usage requirements’ ductility, it is needed to anneal germ tubes. After slugs are extruded into germ tubes, metallic molecule structure changes and has stress. In order to eliminate this kind of stress and reach required ductility, it has to be annealed. Annealing oven adopts electricity heating way, tidy and safe. Conveyor chains put every germ tube into “c” type boat. Germ tubes cycle in oven’s chamber with “c” type boat, annealing is finished at this process. Germ tubes are poured at unloading point, and sent to next step by conveyor chains. Tube-in conveyor chains use stepless speed regulation, which can keep the same pace with previous equipment. Oven chamber uses suspension type structure which is convenient to maintain and makes conveyor boats move smoothly, reducing the phenomenon of tube’s falling and pressing, so it can improve products’ percent of pass. Oven’s internal bladder adopts excellent stainless steel. This equipment also uses excellent heat preservation material and better heat barrier material, greatly cutting down energy and reducing cost. main technical parameters: 1. Production speed: 60 pieces per min 2. Tube specification: φ11mm-φ38mm 3. Electro thermal power: 4kw×8 4. Motor power: 0.75kw 5. Working temperature: 200-500℃ 6. Conveying hopper shape: c-shape 7. Working time: 150 sec 8. Dimensions (including conveyor chains): 4627×1300×3040 mm 9. Net weight: 1800 kg 10. Configuration according to the buyers’ specific requirement

Wire Drawing Machine

Get Price Quote

Wire drawing machine advantages • transmission through reducer in oil bath • reel with electronic friction • very functional operator panel • optional electronic winding unit • strong, solid frame • very reliable • compliance with the required standards the vm6p, vm10p and vm12p models are multi-pass straight-line drawing machines designed to process ferrous, non-ferrous and noble wires, which are available in two versions: variable speed, adjusted via potentiometer, or 2 fixed speeds (vm6p2, 10p2 and 12p2) in both cases the movement is ensured by a three-phase motor with alternating current transmission through reducer in oil bath and is able to guarantee a drawing speed of up to 80 mmin. explanation the movement is ensured by a three-phase motor with alternating current transmission through reducer in oil bath and is able to guarantee a drawing speed of up to 110 mmin. The steel conical reel with hard chrome surface comes with a mechanical clutch with auto-leveling tempered discs for the constant tensioning of the wire and the smooth startup of the system; a closed-circuit cooling and lubrication device ensures the temperature dispersion of the die-holder group and the motorized conical reel during processing in order to delay wear and collect scrap materials. An easily accessible, highly functional control panel allows the operator to manage all operations in an immediate, streamlined fashion. Activations via foot pedal when the machine is both open and closed. The vm6p, 10p and 12p drawings are equipped with optional electronic winding, and safety protection in accordance with internationally required standards.

Wire Flattening Machine

Get Price Quote

Wire Flattening Machine, Slitting Machine

Strip Sealing Machine

Get Price Quote

PLC – Microprocessor. Disc Feeding Attachments. Print Registration Control (PRC). Set of Change Parts. Pocket Forming & Cooling Attachment. Roto Print Attachment

Wire Butt Welding Machine

196,000 Per Piece

1 Piece (MOQ)

Pneumatic Perfume Crimping Machine

Get Price Quote

Perfume Bottle Crimping machine is a single head machine, which is the higher version of Hand operated Perfume Crimping Machine. Based on the highest efficiency factor, we have taken a lead from the existing manufacturers and Exporters Characteristics Suitable for small, medium and lab purposes Very much useful, where there is less human labor is available The operating strength of human hands for crimping is replaced by a pneumatic cylinder So, ladies can also easily operate this machine for long time Machine Structure and working Made from Mild steel for main body and structure The tool is made with special material which is machined and hardened to get the correct crimping each time Operating of this machine is also very much simple A pedal operating foot switch is provided with the machine to do each crimping When once pressed, a single crimping is done with perfect tight The foot switch is very soft to operate Specifications Number of Collets: 1 Single Head. Can Crimp Perfume Bottles and other similar bottles Crimp cap range: 15mm – 32mm at a time as per collets (Tool) size. Output: 25 crimped bottles per minute depends upon labor skill. Machine type and Model: Pneumatically operated Perfume Bottle Crimping Machine (DEPBCP 16) Crimp Tightness adjustable by setscrew on the collets GMP Models also available Semi-automatic Pneumatic Machines also available on request Automatic Filling and Crimping Machines are also manufactured by us as per customer specifications Special Features Machine is small in size and can be carrying with hands To add a FRL unit (fluid regulator and liquid sump) with the compressor to avoid, humidity and water going to pneumatic fittings Each machine is provided with a pneumatic pressure control unit with which we can adjust the air pressure required for usage Machine is having a bottle resting platform, which is spring loaded The machine is compatible with 16mm tool, or 20mm tool as per production requirements This enables the bottles to tightly press towards the tool during crimping. (optional attachment can be a pneumatic cylinder for clamping the bottles to the tool at extra cost) Tool tightness to the neck can be adjusted as per bottle neck variations When once the bottle is rested and clamped, the only operation manually done is to press the pneumatic pedal switch Our standard machines comes with polyurathene tubes and push in fittings Each pressing and release will do each crimping adjustments for heights as per various bottle sizes can be done with the crimping head, by unscrewing, adjusting and tightening the hand lever at the back side on the head Pneumatic Crimping Machine is having a pu8 (that is 8mm outer diameter and 6mm inner diameter tube), tube; accordingly, you may have to fit the connection on the compressor Any sizes of crimping tools from 15mm to 30mm can be supplied from us at extra cost. Maximum net weight for the machine will be 20 kgs Normally, the compressor comes with 1/4" BSP fittings The packing size will be 23" l x 10" w x 14" b. the gross weight including wooden case will be 30 kgs

Friction Drive Coil Winding Machine

Get Price Quote

wire form components

Get Price Quote

ultrasonic wire cleaning machine

Get Price Quote

Appropriate liquid is poured in the tank for removing specific contamination. Heating if desired is also incorporated. The Job is loaded on jigs. Fixtures, Wire, Baskets or any other convenient method and immersed in tank for prescribed time. Single stage ultrasonic cleaning system is useful with Neutral or Alkaline liquid. Acidic solution to be used with special arrangements. Stainless Steel 316304 grade 1618 gauge construction. Digital and Thermostatic control on heaters.

Hydraulic Wire Cutting Machine

Get Price Quote

Pneumatic Perfume Bottle Crimping Machine

Get Price Quote

Pneumatic Perfume Bottle Crimping Machine is a single head machine, which is the higher version of Hand operated Perfume Crimping Machine. This machine is most suitable for small, medium and lab purposes. Also, this machine is very much useful, where there is less human labour is available. Here, the operating strength of human hands for crimping is replaced by a pneumatic cylinder. So, ladies can also easily operate this machine for long time. Machine Structure and working: AEPBCP16 is also made from Mild steel for main body and structure. The tool is made with special material which is machined and hardened to get the correct crimping each time. Operating of this machine is also very much simple. A pedal operating foot switch is provided with the machine to do each crimping. When once pressed, a single crimping is done with perfect tight. The foot switch is very soft to operate. Number of Collets: 1, Single Head. Can Crimp Perfume Bottles and other similar bottles. Crimp cap range: 15mm – 32mm at a time as per collet (Tool) size. Output: 25 crimped bottles per minute depends upon labour skill. Machine type and Model: Pneumatically operated Perfume Bottle Crimping Machine (AEPBCP16) Crimp Tightness adjustable by set screw on the collet. GMP Models also available. Semi-automatic Pneumatic Machines also available on request. Automatic Filling and Crimping Machines are also manufactured by us as per customer specifications.

aluminum tube crimping machine

7,000 Per Piece

1 Piece (MOQ)