woven sack printing machine

140,000 Per Piece

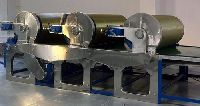

SIX COLOR FLEXO PRINTING MACHINES FOR WOVEN SACK

1,500,000 - 15,000,000 Per Piece

1 Piece (MOQ)

SIX COLOUR FLEXO PRINTING MACHINE FOR WOVEN SACK Features : Ribbed Anti Vibration MS IRON Body for vibration free printing at high speed printing. AC Digital frequency drive.(Optional HMI) Twin High speed Blower with drying system for high speed operation Repeat Print of Plate Cylinder 400mm ~1200mm as standard model. Printing Possibilities (Front + Back) 6+0, 3+3,4+2 Web Guide (Pneumo Hydraulic) - E.P.C Extended Unwinder (Optional) Deco 5 layer Paint for smooth touch Optional Online Gusseting device Surface Winder Optional Auto Tension Controller on Rewinding & Winding

Best Deals from Woven Sack Printing Machine

woven sack printing machine

Get Price Quote

Corona treater for woven fabrics-Corona treatment system is a very effective way to increase the surface tension of virtually any material. Surface treatment is required for plastic filmsfabrics whose normal surface tension is not sufficiently high to permit good wetting by flexo graphic inks. Corona treatment for woven sacks-PPHDPEWoven sacks fabrics has to be corona treated before printing on flexographic printing machine.

woven sacks printing machine

Get Price Quote

Corona treatment for woven sacks-PP/HDPE Woven sacks fabrics has to be corona treated before printing on flexographic printing machine. Corona treater for woven fabrics-Corona treatment system is a very effective way to increase the surface tension of virtually any material. Surface treatment is required for plastic films/fabrics whose normal surface tension is not sufficiently high to permit good wetting by flexo graphic inks. Application : Blown film extrusion single and multilayer for plastic film plants Woven sack roll on- line Flexo printing machine. Extrusion and lamination coating plant for paper industry Sheet line plant Plastic moulded articles Woven sack roll on line flexo printing machine Gum coating on PTFE coat fibre glass cloth PVDC coating on PVC film for pharmaceutical applications.

woven sack printing machine

Get Price Quote

Infeed and Outfeed system provided to maintain tension & good registration. Helical Gears for Smooth running and long life.Twin High speed Blower with drying system for high speed operation Repeat Print of Plate Cylinder 400mm ~1200mm as standard model.Optional Online Gusseting device, Surface Winder and Automatic polycut system, Optional Auto Tension Controller on Rewinding & Winding.

woven sack printing machine

Get Price Quote

Corona treater for woven fabrics-Corona treatment system is a very effective way to increase the surface tension of virtually any material. Surface treatment is required for plastic filmsfabrics whose normal surface tension is not sufficiently high to permit good wetting by flexo graphic inks. Corona treatment for woven sacks-PPHDPEWoven sacks fabrics has to be corona treated before printing on flexographic printing machine.

woven sack printing machine

Get Price Quote

woven sack printing machine, 8 Color Flexo Printing Press Stack Type

Woven Sack Bag Printing Machine

Get Price Quote

Woven Sack Bag Printing Machine, Winders Spare Parts, Shade Card Winder