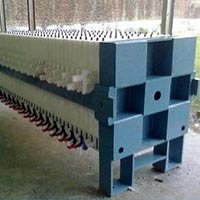

33 Inch Zero Hold Up Sparkler Filter Press

160,000 - 500,000 Per Piece

1 Piece (MOQ)

CENTRAL FEEDING OF UNFILTERED LIQUID ENSURES : SINGLE PASS CLEAR FILTERATION. FULL BATCH RECOVERY OF THE FILTERATE. NO SCAVENGING OF THE FILTERATE. COMPLETE CAKE RETAINS ON THE PLATE. UNIFORM DISTRIBUTION OF CAKE ON EACH PLATE. REDUCE THE COST OF TREATEMENT OF CATALYST, TOXIC CHEMICALS. LESS EXPOSURE TO THE OPERATING PERSON. NO CONTAMINATION OF THE INTERNAL SURFACE OF THE SHELL.

Zero Hold Up Sparkler Filter Press

350,000 - 1,200,000 Per Piece

1 Piece (MOQ)

Description: Sparkler Filter Press is a filtration machine used to filter liquid in pharmaceutical, chemical, beverage, and other industries. Filter Press works on the principle of pressure feeding. Features: Due to the reverse flow of liquid, there is zero hold up in the filter press that leads to complete filtration of the batch. A backwash can provide a facility for continuous operations. No scavenger arrangement is required. The cake, filter aid & solids remain enclosed, allowing filtration of toxic, hazardous & explosive liquids. The top dome structure ensures fast & easy removal of cartridge assembly & cleaning of cake. We can increase the number of plates as per toxic levels of input or filtration requirements.

Best Deals from Zero Hold Up Filter Press

Zero Hold Up Filter Press

Get Price Quote

We are offering excellence in the form of Zero Hold Up Filter Press to enhance the buyers' content. We have an in-house facility, which is used for making stocks. Laced with modern amenities, our storehouse keeps the products away from moisture, rainwater, sunlight, etc.Details : Sizes available 8”, 14”, 18”, 24” & 33” Diameter MOC SS 316 / 316L. Available models 8”, 14”, 18”, 24” & 33” plate diameter. Available with centrifugal / gear / lobe pump. Fitted with pressure gauge, safety valve & airvent. cGMP with documentation.

Zero Hold Up Filter Press

Get Price Quote

cGMP Zero Hold-Up / Sparkler Type Filter Press consist of Stainless Steel Shell & Top cover using bolts to give pressure tight enclosure. The filter cartridge assembly inside the shell consists of several horizontally arranged disc type filter plates with perforated supporting screens, filter media & interlocking cups. The entire assembly complete with pump & piping connection is mounted on a suitable S.S. Trolley. Details : Single pass filtration with no solid bypass. Full batch recovery, no separate scavenging system needed. Proper sealing which allows the filtration of volatile, toxic and inflammable products. Plate pack arrangement ensures any type of filtering media singularly or in combination, can be used to achieve required micron efficiency. Easy removal and cleaning of the cartridge assembly. Closed System ensures filtration of toxic, hazardous, explosive materials, efficiently cleaned and sterilized. Central feeding ensures no solid inside the vessel, complete recovery of liquids. Uniform filter-aid bed can be formed. Jacket can be provided for hot filtration & cooling Available model 8", 14", 18", 24" & 33". Available with centrifugal / gear / lobe pump.

Zero Hold Up Filter Press

110,000 Per Piece

1 Piece(s) (MOQ)

Zero Hold Up Filter Press

Get Price Quote

We are offering highly efficient Zero Hold Up Filter Press that is widely used in different applications like fine chemicals, food industries, pharmaceutical, polymers, perfumes, etc. Our Zero Hold Up Filter Press fulfills all the demands of the filtrations. We make available Zero Hold Up Filter Press in different size range and construction material in order to meet the requirements of the clients. Operation The plate pack assembly consists of plates with interlocking cups, plate rings, perforated screens and filter media. Interlocking cups arranged one above other forms single pipeline. The unfiltered liquid is centrally fed under pressure from bottom inlet. The liquid spreads out equally on each plate fitted with filter media. Solids remains on the filter media and clear filtrate flows through gaps on the supporting rings and collects in the shell, which is led out through outlet pipeline. In this process, solids are evenly distributed on each plate. At the end of the cycle the cake can be maximum dried by applying air or inert gas. The liquid to be filtered is pumped to the tank, where it enters into the individual plates. It passes through the filter media (Paper/Cloth) and crystal clear filtrate comes out through a central channel formed by interlocking cups. The cake formed between the plates can be obtained if required. The Cartridge assembly consists of plates, perforated screens, spacers and fitter media. Interlocking spacers internally form single pipeline. The unfiltered liquid is centrally fed under pressure from bottom inlet. The liquids spreads out equally on each plate fitted with filter media. Solids remain on filter media and clear. filtrate flows through precisely made holes on sides of plates and collects in the shell, which then comes out through the outlet. In this process, solids are evenly distributed on each plate. The cake is then cleaned from the filter material and used again for filtration process. Single pass filtration with no solid bypass Full batch recovery, no separate scavenging system needed. Proper sealing which allows the filtration of volatile, toxic and inflammable products. Plate pack arrangement ensures : Any type of filtering media singularly or in combination, can be used to achieve required micron efficiency.Easy removal and cleaning of the Cartridge Assembly. Central Feeding Ensures No solid inside the vessel complete recovery of liquids. Cake solids can be maximum dried with N2. Complete cake retains over the plate. Uniform distribution of cake on each plate. Uniform filter-aid bed can be formed. Reduces the cost of expensive solvents. Closed System Ensures Filtration of Toxic, Hardous, Explosive materials. Efficiently cleaned and sterilized.

Zero Hold Up Filter Press

Get Price Quote

With our years of experience, our company name figures amidst the most responsive and responsible Suppliers of Zero Hold Up Filter Press. With substantial warehouse that is sprawling over large area, we have the capability to partner with management in performing the detail processes that require handling of the tasks such as sourcing, inspection, internal replenishment to picking positions, packing and shipping. Other Details : Single pass filtration with no solid by pass No scavenger arrangement required The top dome structure ensures fast & easy removal of cartridge assembly & cleaning of cake. Available with centrifugal/ gear/ lobe pump Fitted with pressure gauge, safety valve, air vent , sampling port. High flow rates Low pressure drop Positive sealing arrangement to avoid by passing Easy to operate & low maintenance Cove are “O” Ring sealed High temperature & high pressure design are available. Housing are permanently piped Large-area heavy-duty baskets The filtration area and cake holding capacity can increased or decreased according to requirement. Filter press is available in two size. Deep plate for large percentage of cake holding and shallow plate for small percentage of cake holding capacity. SS pump mounted on SS trolley with heavy duty trust ball bearing caster wheels for easy movement. Provide with by pass system and sample collecting device

Zero Hold Up Filter Press

Get Price Quote

We are offering zero hold up filter press. Features of zero hold up filter press : * range : 8" dia x 8 plates to 24" dia x 24 plates * material : ss 304 & ss 316 * jacket for heating can be provided as option * suitable pump with motor * entire filter press assembly is skid mounted for easy handling * cgmp finish

Zero Hold Up Filter Press

90,000 Per Piece

We are instrumental in providing our clients a comprehensive range of excellent quality Zero Holdup Filter Press Manufacturer In India. Our complete range is designed with top quality of material in accordance with the market norms. Product range Alpro Equipments is a specialty of manufacturing and suppliers all kind of range Zero Holdup Filter Press. Alpro equipments has been actively involved in Zero Holdup Filter Press Manufacturer, which are widely used in Pharma, bulk drugs, distilleries, beverages & varies industries. we are supplier, export and zero holdup filter press manufacturer in india. our product are perform high with low maintance, alpro equipments team are expert to design and fabricate of best Zero Holdup Filter Press with industrial standard. Features of zero hold up filter press: Low noise operation. High output results. Consume less power. Description: Zero hold up Horizontal plate closed pressure filter that meets all the demands for a filtration which would discharge solid free filtrate. Design of filter press is according to cGMP & FDA approval. Other Details: Components are argon arc welded & polished to mirror finish SS jacket can be provided for hot filtration. (Optional) Provides crystal clear filtration by filtering particles up to 1 micron size. No Scavenger arrangement is required No liquid between the tank & the cartridge Top dome structure ensures fast & easy removal of cartridge assembly & cleaning of cake Uniform filter aids & cake distribution SS pump mounted on SS trolley with heavy duty trust ball bearing caster wheels for easy movement Provided with different types of pumps depending on the viscosity of liquid & output i.e. Centrifugal pump, Gear Pump, Lobe Pump, Roto Pump Etc Provided with bypass system, safety valve & sample collecting device No contamination of internal surface of the shell Horizontal plate Zero Hold Up filter press is constructed in such a manner that it prevents evaporation,Oxidation, Leakage & Fumes escaping from product Plates are available in two sizes: Deep plate for higher percentage of caking holding capacity & shallow plate for lesser percentage of cake holding capacity Filter plate & thickness of cake prevents the cake dropping as well as cracking, thus assuring better filtrate quality According to requirement filtration area & cake holding capacity can be increased or decreased

Zero Hold Up Filter Press

Get Price Quote

Zero Hold Up Filter Press that we offer is precisely manufactured keeping in mind the set industry standards. Our Zero Hold Up Filter Press is subjected to stringent quality tests prior to its final dispatch. We are counted among the top Manufacturers and Suppliers of Zero Hold Up Filter Press. WE are efficient enough to process retail as well as bulk orders for Zero Hold Up Filter Press even at short notice period. Details : Manufactured in Ss-304 / 55-3161 55-3161 Quality, Argon Arc Welded and Mirror Polished. Ss Jacket Can Be Provided for Hot Filtration. It is Generally Used to Obtain Crystal Clear Filtration By Filtration By Filtering Particles Up to 1 Micron Size. It Can Be Provided with Different Types of Pumps I.e. Gear Lobe Centrifugal Pump, Depending On the Viscosity of Liquid and Output, Which Can also Be Used for Liquid Transfer. T.E.F.C. Flame Proof Motors Can Be Provided. Provided with Pressure Gauge, Safety Valve, Bypass System, Sampler, Air Vent & Drain System. Can Be Manufactured as per Customer Design Requirement. Cake Formed Between the Plates Can Be Obtained if Required. and Also, It (cake) Can Be Dried Either By Compressed Air or By Inert Gas, Steam. Complete Unit is Mounted On Ss Trolley & Fitted with Ss Bracket, Pu. Bond Castor Wheels for Easy Movement. Scavenger Plate Arrangement to Remove all the Liquid.

Sparkler filter Reverse flow Zero Hold up Filter

85,000 - 350,000 Per Each

Reverse flow filter with SS 316 MOC along with pump and motor mounted on trolley with all standard accessories. Plug and Play model with filter pads in Polypropylene

Zero Hold Up Filter Press

Get Price Quote

• Complete filtration of the batch without any hold up due to reverse flow of liquid hence large saving in time & cost. • Back wash facility can be provided for continuous operations. • No scavenger arrangement required. • The cake, filteraid & solids remain totally enclosed allowing filtration of toxic, hazardous & explosive liquids. • No contamination of internal surface of shell. • The top dome structure ensures fast & easy removal of cartridge assembly & cleaning of cake. • Other features same as standard flow type.

Zero Hold Up Filter Press

Get Price Quote

REVERSE FLOW ZERO HOLD UP TYPE : Here the direction of flow of liquid is exactly opposite to the flow in standard filter i.e. the impure liquid to be filtered enters the filter from the bottom into the center channel & goes to the top of each plate. The clear filtrate flows out from openings on side of plates to the shell & then to the outlet. This flow ensure almost 100% filtration of the liquid which is not so with the standard flow type.

Zero Hold Up Filter Press

Get Price Quote

Application : To filter final product in Pharmaceuticals, Perfumes, I. V. Fluids, Dyes & Chemicals, Activated carbon, Pesticides, Cosmetics, Varnishes, Polymers, Resins & Paints, Sugar syrup, Food, Plant Water Polishing, Fruit juice, Soft drink, Beer & Liquors, Edible & Non Edible oils.Operation : The liquid to be filtered is forced in the chamber by the Tra the filter media of each plate through circular opening on the side of the plates. Under pressure clear Liquid passes through the filter media leaving snsfer pump, where it finds its way to the top ofuspended particles on top of the filter. The clear filtrate runs down through central channel formed by the interlocking cups and exists through the outlet valve. Features : Single pass clear filtration. Full batch recovery of the filtrate. Easy install inside cartridge assembly. Complete cake retains on the plate. Uniform distribution of cake on each plate. Reduce the cost of treatment of catalyst, Toxic Chemicals. Less exposure to the operating person. No contamination of the internal surface of the shell. Advantages : Zero retention in filter vessel.

Zero Hold Up Filter Press

Get Price Quote

Meets GMP norms. Construction follows the latest standards & engineered to perfection. Available models – 8, 14 and 18 inches plate diameter. Available with centrifugal gear lobe roto pump. Fitted with pressure gauge, safety valve and airvent. Gives crystal clear filtration. All contact parts in SS 304316316L. High degree of finish to all Contact parts. Minimum hold up of unfiltered slurry, boost in productivity. MOC: Contact parts S.S. 316 & S.S. 316L and non-contact parts S.S. 304M.S. (as per requirement).

Zero Hold Up Filter Press

Get Price Quote

Zero Hold-Up: The Cartridge assembly consists of plates, perforated screens, spacers and fitter media. Interlocking spacers internally form single pipeline. The unfiltered liquid is centrally fed under pressure from bottom inlet. The liquids spreads out equally on each plate fitted with filter media. Solids remain on filter media and clear. Filtrate flows through precisely made holes on sides of plates and collects in the shell, which then come out through the outlet. In this process, solids are evenly distributed on each plate. The cake is then cleaned from the filter material and used again for filtration process

Zero Hold Up Filter Press

Get Price Quote

Our Zero Hold Up Filter Press 8 machines are high in performance, low in maintenance, dimensionally accurate and breathe in quality and durability. Owing to such unique features these are appreciated all across the globe and are extensively used for crystal clear filtration of pharmaceuticals, chemicals, resigns, beverages, distillery, oil, ink and other industry.

Zero Hold Up Filter Press

Get Price Quote

Zero Hold Up Filter Press

80,000 - 800,000 Per NOS

1 NOS (MOQ)

Zero Hold Up Filter Press, Fluid Bed Dryer, Vibro Sifter Machine

Zero Hold Up Filter Press

Get Price Quote

Zero Hold Up Filter Press, Lab Filter, cellulose filter paper, Bag Filter

Zero Hold Up Filter Press

Get Price Quote

Zero Hold Up Filter Press, Sparkler Filter Press, Inline High Shear Mixer

Zero Hold Up Filter Press

Get Price Quote

Zero Hold Up Filter Press, Stainless Steel Intermediate Bulk Container

Zero Hold Up Filter Press

Get Price Quote

Zero Hold Up Filter Press, Octagonal Blender

Zero Hold Up Sparkler Filter Press

Get Price Quote

Zero Hold Up Sparkler Filter Press, Packing Conveyor, Bakery Planetary Mixer

Zero Hold Up Filter Press

Get Price Quote

Zero Hold Up Filter Press, Filter Press, Tray Dryer, Drying Ovens