Induction Heating Equipment

Get Price Quote

Our world wide appreciation is the result of the power packed performance of our Induction Heating Equipment. This equipment is used for surface heating as well as in forming, forging or rolling applications. It operates smoothly with power sources of range of 1 KW-600 KW. With a frequency range of 500 Hz-20 Khz, our product is suitable to be used in a number of industrial purposes. As one of the top-notch Heat Treating Equipment Manufacturers and Suppliers in India, we ensure the delivery of the quality product to the clients at the most cost-effective prices.

Solar Water Heater

12,000 - 100,000 Per LPD

10 LPD (MOQ)

Best Deals from Industrial Heaters

Solar Water Heater

Get Price Quote

Solar Water Heater

Get Price Quote

We are a popular Supplier of Solar Water Heater. The Heater is the most favorite among customers for its enhanced functionality and unbeatable performance. The packaging is done properly before dispatch. The Water Heater can be obtained from us in bulk or in small quantities as per the needs of the clients. Customers can procure the Heater at pocket friendly rates.

Solar Water Heater

19,000 Per Piece

Solar Water Heater

22,430 Per Piece

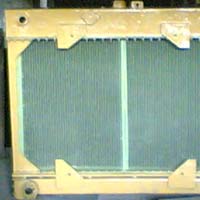

Industrial Radiator

Get Price Quote

Our company is prime Manufacturer, Exporter and Supplier of Industrial Radiator of HEMM / DG SET. We use premium raw materials along with state-of-the-art technology to bring the best in the market. We can make available this Radiator in different capacities all across the globe. We are lauded by many leading industries for our quality control. Each Radiator is minutely checked before dispatching.

Solar Water Heater

40,000 - 46,000 Per Piece(s)

1 Piece(s) (MOQ)

Solar Water Heater

Get Price Quote

Solar Water Heater

Get Price Quote

10 Ton (MOQ)

Our company is the leading manufacturer, supplier and exporter of highly efficient Solar Water Heater. The Solar Water Heaters are available at industry leading prices. Solar Water Heaters are highly efficient and save electricity. The Solar Water Heaters we supply are environment friendly.Description : Bulk orders are only accepted. The Solar Water Heaters are manufactured using latest technology and machinery. It has several attributes like longer performance life, durability and high efficiency. The Solar Water Heater relies completely on the sun to increase its temperature

Bobbin Heaters

450 Per Piece

Solar Water Heater

Get Price Quote

10 Set(s) (MOQ)

We are offering solar water heater. Domestic commercial model solar water heater.tube-58*1800 mm,tank -2 mm thickness with coating,stand 1.5 mm sheet.

Solar Water Heater

15,000 Per Piece

1 Piece (MOQ)

Solar Water Heater

Get Price Quote

Working of the System Evacuated Tube Collector work on "twin glass tube" technology. The Sun's rays fall on the evacuated tubes panel which collects the radiations & converts them into heat energy. The solar heat energy thus collected is used to heat the water passing through the tubes. A temperature difference is created the hot water with low specific gravity rises up & the cold water comes down.(Thermo siphoning Principal)The hot water is then stored in insulated tank above & from there, it is distributed to required end points for bathing, washing, cleaning, etc.

Solar Water Heater

Get Price Quote

20 Set(s) (MOQ)

This is solar water heater from which you can get hot absolutely free for long life.Life of this heater will 15-20 years.Maintenance is zero.From this you can save electricity as well as Nature.

Industrial Solar Water Heater

Get Price Quote

SYSTEM OPERATION SOLAR THERMAL: There are two types of solar water heating systems, based on type of circulation; 1. Thermosyphon 2. Forced circulation All domestic and industrial systems upto 4000 LPD (liters per day) @ 60 deg.C,; works on the principle of thermosyphon. Industrial systems beyond 4000 LPD to any capacity will work on forced circulation principle. Thermosyphon system:: The system works on a principle called "THERMOSYPHON" (Natural circulation).Due to density difference between the cold & hot Water, the lighter hot water flows up into the tank and the heavier cold water enters the collector. Solar radiation incident on the collector panels heats the absorber. This heat is transferred to the water contained in the absorber & becomes less dense than the water in the storage tank. Hot water starts rising and settles at the top of the storage tank. Simultaneously cold water descends to the collector absorber tubes, gets heated up and the cycle repeats. The circulation in the system during the heating process is purely due to the difference of density only. There is no other mechanical moving part, hence the system reliability is very high. At the end of the day when radiation is zero (after dark / sun set) the collector will contain heavier cold water and the tank will have lighter hot water. This will ensure that there will be no circulation during night & hence no conduction losses on account of this. The hot water storage tank is well insulated to retain the hot water temperature and to minimize the overnight temperature drop / heat losses. The Sacrificial Anode (Only for SS tank) prevents the tank from galvanic corrosion. For the monsoon / cloudy days the system is-fitted with Electrical back up heater with thermostat. Forced circulation system: In forced circulation systems, two pumps in tandem are used for circulation of water between collector bank & system insulated tank. The pump operation is controlled by OTC (Differential Temperature Controller), which is fitted Inside the Control panel. OTC senses the cold & hot water temperature through two sensors, one fitted at the bottom of the tank to sense cold water temperature & the other fitted at the top of the last collector of the row in the collector bank, to sense the hot water temperature inside the collector The difference in temperature between the two sensor points is the criteria for the operation of the pump that is controlled through DTC. This temperature difference can be set between 0 to 10 deg, C. Solar radiation falling on the collector heats up the water inside the absorber. The temperature of water starts gradually increasing compared to the water temperature inside the tank. When this temperature difference between the sensor points reaches the preset temperature difference in DTC, the pump is switched "ON". This will result in entry of cold-water form the system-insulated tank into the collector bank & discharge of hot water from the collector bank to the system insulated tank. The process of switching ON & QFF of the pump & circulation of water continues till the end of the day. By the end of the day, the entire quantity of water in the tank reaches the system-designed temperature, provided the radiation level is at minimum of 800 watts per sq.mtr. The process of switching ON & QFF of the pump & circulation of water continues till the end of the day. By the end of the day, the entire quantity of water in the tank reaches the system-designed temperature, provided the radiation level is at minimum of 800 watts per sq.mtr.

Solar Water Heater

14,900 Per Piece

Industrial Solar Water Heater

Get Price Quote

We supply Solar Water Heater Industrial, that is widely used in different automotive and industry applications. Manufactured using quality material, these products are available in both metric and inch sizes. Our range of solar water heater is well known for their dimensional accuracy, corrosion resistance, perfect finishes and durability.

Solar Water Heater

Get Price Quote

Non - pressure solar water heater Non-pressure solar water heater is a kind of compact system of solar collector and water storage tank. The whole system relies on the different density of cold water and hot water, thus Non-pressure solar water heater also called thermo-siphon solar water heater. The system can work without the circulation pump and no heat pipe connection. Cold water directly filled into the vacuum tubes, the vacuum tubes gather energy and heat the cold water, the lighter hot water tank and cold water come down then be reheated. That is how the water does circulation by itself. Please see (fig.1) for its working principle. Non-pressure solar water heater system is most economical and suitable product for low latitude countries and regions, especially for Asian, India, Africa, Oceania, South America and South part of North America. Optional accessories: controller and electrical heater. Product model: i. ECO; ii. AT; iii. EVERHOT Vacuum tube: Ø47-1500mm, Ø58-1800mm co-axial structure high borosilicate 3.3 glass vacuum tube. Inner tank material: SS304 L (Low Carbon)-2B (Food Grade)Stainless Steel (SAIL/ JINDAL make only) Outer tank material: Color powder coating steel / Stainless steel/ Precoated Galvanized (JINDAL/ UTTAM GALVA). Frame : Galvanized steel plate with thickness of 1.5mm; MS powder coated 1.5mm thickness. Frame angle : 250, 380 or 450 Capacity of water tank: 98L ~ 288L. Heat preservation layer: high pressure automatic polyurethane foaming layer with thickness of 50mm to 55mm. Heat preservation : 72 hours. Hailstone resistance: Dia≤25mm.

Evacuated Tube Solar Water Heater Hot Max

Get Price Quote

Avail the Evacuated Tube Solar Water Heater HOT MAX model that is offered to the clients at affordable rates. The Evacuated Tube Solar Water Heater HOT MAX is high on demand in the market for high performance and durability. Standard Collector Size Flat Plate Collector (9 fin)Width - 1150mm (East -West)Length -2080mm (South -North)Evacuated Tube-Glass Tube, Collector (for 500 ltr)Width - 3100mm (East -West)Length - 2200mm (South-North) Weight of the Collector with water & legs Flat Plate collector - 46 Kgs.Evacuated Tube-Glass Tube, Collector (for 500 ltr) - 310 Kgs In domestic systems to heat water @ 60 deg C per day One Flat Plate collector is used per 100 lit.For 100 LPD system - 1 collectorFor 200 LPD system - 2 collectorsOne Evacuated Tube Collector assemlyFor 100 LPD system - 15 nos evacuated glass tubesFor 200 LPD system - 30 nos evacuated glass tubes In Industrial systems (above 500 LPD) to heat water @ 60 deg C per day One Flat Plate collector is used per 125 lit.For 1000 LPD system – 8 collectors,For 2000 LPD system – 16 collectorsOne Evacuated Tube Collector (assembly of 70 tubes each) is used per 500 ltr.For 1000 LPD system – 2 manifolds collectors,For 2000 LPD system – 4 manifolds collectors The systems can be designed to heat water at temperature up to 80deg. C Area required for installation per 1000 LPD System @ 60 deg. C is For Flat Plate collector systems - @ 32 sq.mFor Evacuated Tube Collector systems - @ 24 sq.m. Systems are available for pressures >1.0 bar