Scrap Straightening Machine

190,000 Per Piece

Rebar Scrap Straightening Machine is useful equipment for construction sites. This Scrap Bar Straightening Machine is useful equipment to straighten the scrap bars, to be put to use again. It also has a provision to cut crocked ends of the bar so that it can be put into the machine easily. Backed by latest technology support, these bar scrap straightening system help in delivering optimum performance support as desired by the customers. Straightens tangled and twisted steel bar such as scrap. Extremely effective for civil construction as straightened steel can be effectively put back to use. These scrap bar straightening machine mainly used in construction site and steel processing plant. Suitable for straightening hexagon bar, square bar, and Profiles brass bar convenience to change wheel easy and simple to adjust. Straightening machine is a metal bar, pipe, wire, and other equipment for straightening. Straightening roller straightening machine through the bars of pressure for them to change, such as straightness. There are two rows of straightening roller, the number of ranges. There is also two roller straightening machine, relying on two rollers (Concave Intermediate, hyperbolic roll) the perspective of the different changes in the diameter of the material straightening. Type of straightening of the main pressure, balance roller straightening machine, shoes roller straightening machine, anti-rotation bending leveler and so on. This process of straightening machine is: the location of the roller straightening products and the direction of the movement as a point of view, two or three of the initiative is a pressure roller, driven by the motor for rotating in the same direction, on the other side of a number of A small roller was driven roller pressure, they are relying on a rotation of the rod or pipe so that the friction of the rotation. In order to achieve roller on the products required by the compression of this small roller at the same time or separately adjustments backwards or forward position, in general, the number of roller more after straightening products, the higher accuracy. Products have been biting into the roller, continue to make a straight line or rotary movement, making products to bear all aspects of compression, bending, squash such as deformation, to reach the final straightening. Features Smooth straightening & Auto cutting mechanism. Handy to operate and control the machine ensuring safety whilst in use. Hi- speed accurate straightening. The machine incorporates an overload value, which is designed to operate in case of overload. The machine runs on 3- phase power motor and is cost effective in power consumption Machine Helps in avoiding wastage of steel and encourages use of straightened smaller diameter bars in involved projects. Comes with hyperbolic straightening device that straightens bars without damaging ribs. Providers high work efficiency and safe operating environment. Avoid wastage of steel and re-use smaller dia. bars for your project needs Cutting Device to cut off extra lengths of bars Hyperbolic Straightening device straightens without damaging the ribs Easy to operation, low noise, low cost, high profit.

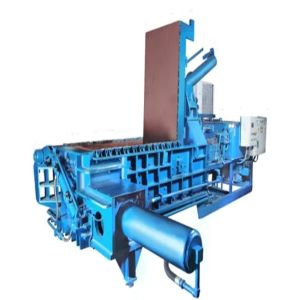

Automatic Scrap Baling Press Machine

750,000 Per Piece

1 Piece (MOQ)

Best Deals from Waste Machinery

waste paper recycling machine

Get Price Quote

1 Piece (MOQ)

Hydraulic Waste Baling Machine

245,000 - 455,000 Per piece

1 piece (MOQ)

Waste Shredding Machine

250,000 Per Units

Scrap Bell Press Machine

280,000 - 1,000,000 Per no

Scrap Bell Press Machine, Ball Transfer Unit, Hydraulic Pallet Trolley

waste water filtration machine

Get Price Quote

waste water filtration machine, bio gas installation services