Vibro Sievers

75,000 - 475,000 Per Set

1 Set(s) (MOQ)

We offer Vibro Sievers to our respected customers at affordable price. The best solutions for screening & grading of dry & wet materials are provided by us as per the specific requirements of the customers. In comparison to other sievers, it is very low in maintenance. Its light weight, and ease of handling makes it a perfect solution. Its operation is efficient and clean. Basic Features Light weight & easy to handle. Easy Assemble & very low time for cleaning. Efficient & Clean Operations. Can be fitted online with other machines, addition of additives, dust pipeline. Single Deck or Multiple deck design, even customized solutions. Very low Maintenance as compared with other options of sievers. Can Handle almost all types dry & wet materials. Direct Vibrations to screen results in self cleaning of screen during operations. Customized Solutions In Vibro-Seiver Multiple motors for high power Multi Deck with Hinge Multiple Mounting Options Various MOC Mesh with Bouncing Balls Mesh with magnetic separator Addition of additives online Fix mesh / removable type Dust suction pipeline Food / Chemical Grade seals Design of Seiver can be Square OR rectangular with various levels & screens Screens with ultrasonic system can be provided Customized solutions can be offered on specific request.

Capacity : 500 Ltr

Material : Stainless Steel

Voltage : 220 V

Frequency : 50/60 Hz

Automation Grade : Semi-automatic

Material Grade : Ss304

...more

Vibrating Screen

85,000 Per piece

1 set (MOQ)

Basic Features of CVS Series Vibro-Seivers Vibro-screens by Clarion Enterprises 1. Light weight & easy to handle. 2. Easy Assemble & very low time for cleaning. 3. Efficient & Clean Operations. 4. Can be fitted online with other machines, addition of additives, dust pipeline. 5. Single Deck or Multiple deck design, even customized solutions. 6. Very low Maintenance as compared with other options of sievers. 7. Can Handle almost all types dry & wet materials. 8. Direct Vibrations to screen results in self cleaning of screen during operations. Customised Solutions in vibro-seiver 1. Multiple motors for high power 2. Multi Deck with Hinge 3. Multiple Mounting Options 4. Various MOC 5. Mesh with Bouncing Balls 6. Mesh with magnetic seperator 7. Addition of additives online 8. Fix mesh removable type 9. Dust suction pipeline 10. Food Chemical Grade seals 11. Design of Seiver can be Square OR rectangular with various levels & screens 12. Screens with ultrasonic system can be provided 13. Customized solutions can be offered on specific request.

Material : Stainless Steel

Color : Silver

Automation Grade : Automatic

Application : Industrial

...more

v cone blender

375,000 Per Piece

1 set (MOQ)

We take pride in presenting V Cone Blender to our customers. Various types of blades are available for Inner Agitator shaft. On its outer body, heating or cooling jacket can be provided. On final application, material of construction can be changed. For special applications, it is possible to equip the blender with solid intensifier bar the design of which facilitates easy removal. This quality is available for economical prices. Basic Features V shaped design in stainless steel 304/316 construction Manually operated Butterfly valve for discharge clearance Hinged stainless steel charging openings Mirror finish on interior surfaces 150 grit/Matt finish on exterior surfaces Non-Stainless steel components are (harrished with a copy pain). Safety railings with limit switches for bigger size machines Drive motors are of TEFC design 3 ph. 50 Iiz Control panels with push balloons and Emergency stops are provided Timer Switch provided on Panel for Mixing time setting Adjustable 0.5-5 Mints. Special Features Inner Agitator shaft can be provided with various types of baldes Thru Shaft with liquid spray system can be provided during mixing process Heating/ Cooling jacket can be provided on outer body Variable Speed of V-Cone can be possible by providing addiornal VFD Dosing of Additives with specified volume/ sec can be added during process Material of construction can be changed depending upon the final application For application requiring dispersion of minor ingredients , and/or breaking up materials, which tend to form agglomerates, the blender can be equipped with a solid intensifier bar (beater or pin type). Which is designed for ease of removal

Type : V Blender

Certification : CE Certified

Weight : 100-1000kg

Color : Silver

Voltage : 220V

Application : Industrial Usage

Automatic Grade : Automatic

Power : 1-3kw, 3-6kw

Driven Type : Electric

Feature : Durable, Low Maintenance

Warranty : 1year

...more

twin shaft crusher

35,000 - 1,250,000 Per Set

1 Set (MOQ)

We have made ourselves a prominent figure by offering a wide assortment of Twin Shaft Crusher. Its special design makes sure that the level of sound produced by this does not exceed the admissible standards. it can be easily displaced thanks to its compact dimension and light weight. It is easy to maintain and can be made available in stainless steel construction at the request of the customers.

Warranty : 1 Year

Power : 55x2 - 200x2 Kw

Weight : 7.5t

Weight : 9-29.5 Tons

...more

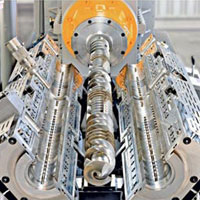

Twin Screw Extruders

550,000 - 7,500,000 Per set

1 Set (MOQ)

Indulged in the customers’ needs with excellence, we are involved in offering Twin Screw Extruders. We make them available in any size as per the requirement of the customers. Their effective design makes them easy to clean and produces better results of heavy as well as light mixing. They are made of special steel which is renowned for its high wear resistance. It is easy to change their complete element screw shaft. Basic Features : Very Economically priced robust & strong design of Gear box for heavy duty Kneading at High Speeds Machine barrel is CNC machined for Water Cooling Jacket for effective cooling Easy to clean design All Individual Controls for heaters & cooling section for accurate Temp. Control Additional (Thermal) Heat transfer unit provided for energy savings Gear Box is fitted with Oil Circulating Cooling Pump Very Effective design for better Result of heavy as well as light mixing Segmented Screw Elements & liners to reduce the wear & tear operating cost All wear parts Are manufactured from a very Special Steel for High Wear resistance. Also Coated for better wear life. Easy for changing of complete Element screw shaft Very Wide range of production Capacity for Powder Coatings Section from 5 Kg/ hr. To 1250 Kg/Hr. Machines. Very strong design back up all machines technology upgradation. Special (optional) Features : Thru Cooling for twin Shaft Segmental barrel Additional feeding Points Special design Elements High feed rate elements water Heating System in place of electrical heaters Additional process length

Type : Twin Screw Extruder

Certification : CE Certified

Color : Mulit Colour

Voltage : 220V

Capacity : 100kg/hr

Frequency : 60Hz

Power : 10-15kw, 15-20kw

Driven Type : Electric

Warranty : 1yrs

...more

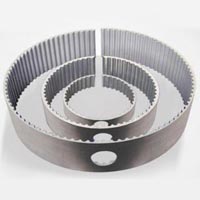

Twin Screw Extruder Machine Spares

1 Set(s) (MOQ)

We are manufacturers & suppliers of spares for all types of twin screw extruders (co-rotating type), the lengths of extruders can be ld = 12 16 20 24 36 40 46 46 etc. The spares can be supplied as per samples drgs like - feed screw elements, kneading elements, liners, barrels, shafts. The complete set of barrel liners & screw shafts can be supplied on request the complete refurbishing of screw shafts, barrel & machine can be done at our works. The wear parts can be made in high wear resistance steel with special vacuum hardening process done along with specially coated for for wear resistance.

Type : Spares for all types of Co-Rotating Twin Screw Extruders

Brand Name : CLARION

Application : Extruder machines

Type : feed Screw elements, Liners, barrel, Shaft, Kneading elements, pressure elements, GS Elements

Quality : 1 set

After-Sales Service Provided : 12 months

Screw Design : Any Design

...more

Spares for Air classifying Mill

We are manufacturers of spares for various types ACM machines like liners, Hammer plate, Pin Plate, Classifiers, feeder system, Cyclones, Dust Collector bags, Rotary Air lock valves, Pneumatic operated Valve system.

Brand Name : CLARION

...more

single shaft crusher

125,000 - 2,500,000 Per Set

1 Set (MOQ)

As a top Manufacturer and Supplier in the industry, we bring forth Single Shaft Crusher. It is used for crushing the granular, cake bulk, and powder like products like line, fertilizers, cement, sugar and other materials which are lumpy. Made from carbon steel with manganese, its knives provide incomparable abrasion resistance during crushing. It doesn’t get heated up while in use. Its low operating cost and low power consumption make it popular. The Basic Characteristics Type of Material Physical properties, hardness, breaking power, adhessive ness Size of Input lumps & output size desired Crushing capacity Capacity per Hr. In Cubic meters. Temp. Rise during crushing / Chemical properties change during crushing Dust generation during crushing Close loop / Close Circuit Processing

Type : Crusher Spare Parts

Material : Brass, Metal

Application : Crusher Use

Weight : 1-5kg

Color : Silver

Surface Finishing : Polished

...more

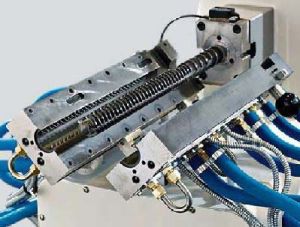

Single Screw Reciprocating Extruder (PCS 46)

225,000 Per set

1 set (MOQ)

Relying on our know-how in the industry gained over years, we, as a Manufacturer and Supplier of Single Screw Reciprocating Extruder (PCS 46) have put us in the top band of the industry. It can be easily cleaned in a short time span. Our customers can also save their costs as it consumes less heat and power. It also takes lesser time and energy in case of a power failure. Advantages No need of additional lab extruder for product development, shade / color matching, RM testing Easy & fast cleaning due to short length, easy & fast cooling due to water heating system Wide range of products can be produced on single screw extruder - like PU, PTFE, low curing, etc. Running cost is low as compared with Twin Screw - Low Power, Low heating cost Small batches can be easily possible Thorough cleaning is possible in small time span. Consistence product Quality possible due precise Temp Control, no problem of jamming, no problem of product deletion Low maintenance cost as compared with Twin Screw Modular design of Screw Elements to felicitate the change in kneading / feeding lengths Thru Cooling Shaft - ensures the controlled process temp. / easy cleaning of screw & avoiding deletion in the barrel. process length is much less than the Twin Screw extruder, ensures less residence time for product. machine is easy to operate If power failure occurs - takes less time / less energy for restart Due close loop heating cooling system - load on chilling gets reduced drastically Disadvantages Fine processing is limited to certain extent ( in case of rejection processing) requires extra care to be taken Spares cost is high ( but / kg cost is low as compared with twin) Thorough Cleaning is time consuming / you may need to keep spare set of Screw Shaft

Type : Single Screw Extruders

Certification : CE Certified

Application : Industrial

Weight : 200-400kg

Color : Silver

Voltage : 110V, 220V

Power : 1-3kw, 3-6kw

Driven Type : Electric

Warranty : 1year

...more

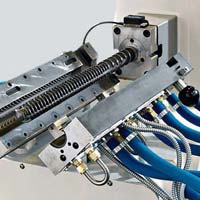

Single Screw Reciprocating Extruder (PCS 30)

1,675,000 Per set

1 set (MOQ)

Being an extraordinary figure in the industry, we offer a broad range of Single Screw Reciprocating Extruder (PCS 30) to our customers. This versatile and compact small scale extruder is used for customers sampling, research and development and color shade matching. Its scale up capabilities offer top notch efficiency and flexibility. It is easy to use, economical and user-friendly. At reasonable rates, we provide it in safe packaging. Details The Clarion make laboratory Kneader PCS 30 is a versatile, compact small scale compounding extruder for research and development, color / shade matching and customer sampling. This easy,economical, user-friendly laboratory kneader offers similar process characteristics as production scale PCS series machines. Samples from 300gms up to 40 kg/h. Based on its process scale-up capabilities it qualifies as a universal laboratory compounder offering a high grade of efficiency and flexibility. Standard Features and Advantages : Representative data from laboratory samples Throughput rates up to 20 - 40 kg/h Standard Split barrel design for easy access and cleaning, easy maintenance Fine temperature control with independent heating Cooling Zones Standard segmented screw, Liners for easy replacement of wear parts Variable screw speed to match desired properties Optional - Feed Screw with hopper can be installed for small batches Optional – Cooling Roller with belt for the small batch production. Detailed List of Basic Components Inlet hopper Complete barrel assembly with Screw Elements & Liners set fitted on barrel Discharge die with cooled chute Gearbox with Motor drive Main Drive Motor Operator panel with all standard accessories Volumetric Feeder Assembly (Optional) Chill Rolls (Optional) Base Table with Heat Cool Unit Leveling Screws

Type : Single Screw Extruders

Certification : CE Certified

Application : Industrial

Weight : 200-400kg

Color : Silver

Voltage : 110V, 220V

Power : 1-3kw

Driven Type : Electric

Warranty : 1year

...more

Single Screw Masterbatch Processing Extruder

7,250,000 Per Piece

1 Piece (MOQ)

Utilizing our high-tech machinery and world class facility, we as a Manufacturer and Supplier, aim to fascinate our customers by merit. Single Screw Masterbatch Processing Extruder on offer is available in an assortment of varieties. The raw material used in manufacturing is of top grade quality. The manufacturing process is carried out by a team of skillful experts who put their best efforts to make sure only best possible quality is produced by us.

Automatic Grade : Automatic,semi-automatic

...more

Single Screw Extruder - (reciprocating)

12,000 Per 92000 Set

1 Set(s) (MOQ)

We are offering single screw extruder - (reciprocating) etc. We are the only manufacturers of these type of extruders in India. The basic construction is same as buss swiss. We have range from 30-1200 kgs hr. Machines for powder coatings powder mfg., Toners, Plastic master batches, Chocolates, PVC granules, food processing, etc.

Brand Name : CLARION

...more

Twin Screw Extruder Replacable Spares, Single Screw Extruder Replacable Spares

We are manufacturers & suppliers of wear parts for our machines as well std. machines available in marker like Single Screw Extruders ( PCS-32 to PCS-100), Twin Screw Extruders, Parts like Elements, Liners, feers, etc. ACM machines spares - feed liner, Liners, pin plate, Pins, hammers, Classifiers, etc.

Brand Name : CLARION

...more

pre mixer

75,000 - 1,250,000 Per set

1 Set (MOQ)

Growing with the dynamic needs of clients, we are engaged with providing a wide array of Pre Mixer to our customers. During mixing time, the power consumption is very low. Due to a lesser number of contact parts, an easy and fast cleaning. It is easy to operate and maintain thanks to its compact design which facilitates better space utilization. It is easy to handle as its top cover is light weight. Advantages : Very low power consumption at the time of mixing time is very low. Batch capacity 50-400 kg. (P-50, P-100, P-400). Easy & Fast cleaning possible because of very less contact parts. Easy operating and low maintenance. Mixing Time adjustable for different formulations. Compact Design for better space utilization. Light structure but still vibration free operations. Light weight top cover for easy handling. Easy clamps for fast operations. Interchangeable mixing blades. Specially designed for powder coatings manufacturing plants . Pneumatic operated Valve for easy & fast opening & closing. All Contact Parts MOC SS304 for better cleaning & long life

Color : Silver

...more

powder coating powder manufacturing plant & machines

We at Clarion Enterprises An ISO 9001-2000 certified company by BSCIC-JAS-ANZ. We are the only company in India to produce Single screw Extruders (Buss swiss type) as well as Twin screw Extruders (AVP Type). We are manufacturing & exporters of Machines for Powder Coatings ( range 30 kg – 1800 kg hr). We are also manufacturing Special Purpose Machines (SPM) for various applications, mainly for automobile spares manufacturing firms. We have developed Single Screw Reciprocating Extruder (Kneader equivalent to Buss Kneader Swiss) & Twin Screw Extruder for Powder Coatings. We are also manufacturing the complete Plant for Manufacturing Powder Coatings it includes, ACM Pulvariser, Premixer, Vibro-Sievers, Double Cone Mixers, Compact Cooler Crusher (Kibbler), Containers, rack Storage System, for Automation of Plant on Turn Key basis also. In Addition we have developed & supplied Resin Manufacturing plant (Epoxy & Polyester Resin) along with technology transfer. Now we have started manufacturing the Powder Coatings Powders with quality product to improve the machine quality, reliability & spares life analysis. We are offering these services for powder coatings powder manufacturing on labor charges basis also, it will give a chance to new manufacturers to develop the market first & then start manufacturing at own. This facility can be offered to existing powder manufacturers also to cater the more orders. We are the only company in India which gives technology for Epoxy & polyester Resin Manufacturing technology. These resins are basic Raw materials for Powder Coatings Powders. Also we are manufacturers of plastic & rubber recycling machines – like extruder, aglo, plastic grinder etc. Also we are producing diesel fuel oil manufacturing plant from waste scrap plastic rubber capacity of 1.5-2 ton day, 3-5 ton day.

...more

Masterbatch twin screw extruders

1 Set(s) (MOQ)

We are manufacturers & suppliers of various types of master batch compounding extruder machines, like twin screw & single screw extruders, the applications can be pvc compounding, masterbatch compounding, black masterbatch compounding, special purpose application in compounding.

Type : Master batch making twin screw extruder machines

Brand Name : CLARION

Application : Colour master batch making, PVC Compounding, Black masterbatch making, plastic Granuals compounding

Type : twin Screw Extruder, compounder,

Quality : 1 set

After-Sales Service Provided : 12 months

Screw Design : as per requirements / std.

...more

master Batch Single screw Extruders Reciprocating Kneaders

1 Set(s) (MOQ)

We are manufacturers & suppliers of single screw reciprocating extruders for the aplication of compounding of masterbatch.

Brand Name : CLARION

Application : master batch, Compounding, PVC Compounding, Colour masterbatch, Black masterbatch,

After-Sales Service Provided : 12 months

Screw Design : as per requirements / std.

...more

Horizontal Ribbon Blender

65,000 - 4,500,000 Per set

1 Set (MOQ)

With a firm dedication towards delivering the unrivaled quality, we present a wide range of Horizontal Ribbon Blender to our customers. It consists of U-shaped horizontal trough and a specially designed Double Helical Ribbon Agitator which rotates inside. Fast and efficient blending is ensured owing to its agitator construction which provides a triple mixing action. A perfect balance of dimensions and configuration is struck to cause a movement avoiding dead spots and providing rapid product discharge. Advantages : Effective Blade Design, to achieve better mixing results Available in SS or MS steel of construction capacity range from 40 ltrs to 9000 ltrs working volume Available in Water cooled jackets for heat sensitive products. Custom made solutions can be possible. Easy cleaning & complete drain Possible due special design of blades Variety of dry Powders can processed with single machine. Blades can be changed for different types of applications Can be fitted with on line with other machines to optimize the process.

Type : Ribbon Blender

Certification : CE Certified

Weight : 100-1000kg

Color : Blue

Voltage : 110V, 220V

Application : Blending

Automatic Grade : Manual

Power : 1Kw

Driven Type : Electric

Feature : Durable, Low Maintenance

...more

High Speed Mixer Machines

135,000 Per piece

1 set (MOQ)

We are offering High Speed Mixer Machines. Advantages of the P-Series Mixing system § Very low power consumption at the time of mixing time is very low. § Batch capacity 50-400 kg. (P-50, P-100, P-400). § Easy & Fast cleaning possible because of very less contact parts. § Easy operating and low maintenance. § Mixing Time adjustable for different formulations. § Compact Design for better space utilization. § Light structure but still vibration free operations. § Light weight top cover for easy handling. § Easy clamps for fast operations. § Interchangeable mixing blades. § Specially designed for powder coatings manufacturing plants . § Pneumatic operated Valve for easy & fast opening & closing. § All Contact Parts MOC SS304 for better cleaning & long life.

...more

hammer mill pulverizer

65,000 - 2,500,000 Per Set

1 Set(s) (MOQ)

Charming our customers, we present a vast assortment of Hammer Mill Pulverizer. It finds its use in any size reduction job. It is equipped with low maintenance and longer life due to its heavy duty construction. It is economical to use and easy to install. Customers can get the outer shell lined with any of MS, cast iron or special steel depending on their choice. Details : Clarion's Pulvarizers & hammer Mill Crushers can be used for any size reduction job. The heavy duty construction of Mill Crushers gives better life with low maintenance. It is very easy to install and proven economical. The outer shell of Mill Crusher is lined throughout with MS / Cast Iron / Special Steel as per customers choice. One can use these machines to achieve desired particle size. Operating Principle Raw Material is fed by screw feeder (single / twin / three screw) on periphery of crusher through a hopper into the grinding chamber. It will minimize air pressure, greatly reducing dust problems. For some material suitable ventilation is recommended by introducing air on the discharge side of the crusher, this will prevent a dusty atmosphere at the inlet of Mill Crusher. The swinging hammers in Mill Crushers crush the materials along the stationery liners before discharging through a perforated screen at the bottom; replaceable bar type screen is available for specific application. Different combinations of screen, hammer can achieve almost any result. Applications : The Hammer Mill Crushers are used for crushing or grinding materials such as - Sugar, Pigments, Limestone, Glass, Charcoal, Lignite, Clay, Sand, Phosphate, pesticides, Fertilizer, Aluminium Oxide, Slags, Coke, Silica, Bauxite, Dolomite, Grain, Barytes, etc. Advantages High grinding tip speed up to 20000 fpm & can be adjusted as per requirements. Hammer mill Crusher's are specifically designed to withstand the heavy loads to grind abrasive materials. Heavy duty, replaceable, wear resistant plates in mill. specially treated / hard faced / heat treated hammers. Rigid rotor assembly. Customized screens / Std. Screens. Hammer mill crusher is provided with rubber lining to do Dust-tight or water-tight operations. Basic MS SS Models / GMP Models / Chemical resistance steel construction is available on request.

Type : Machinery

Brand Name : Clarion

Condition : New

Warranty : 12 Months

After-Sales Service Provided : Yes

Country of Origin : India

...more

Double Ribbon Blender

We are offering clarion make crb series horizontal - ribbon blenders ribbon blender comprises of a u-shaped horizontal trough and a specially designed (as per application) double helical ribbon agitator rotating within. Ribbon blenders are based in a proven agitator construction that provides a triple mixing action ensuring fast, efficient blending. The dimensions and configuration of the ribbons are carefully balanced to provide a movement of material within the container that avoids dead spots, thorough mixing of products and gives rapid product discharge. An alternate design is the paddle agitator. The paddles are positioned to move the material in opposing lateral directions as well as radially. The paddle design is generally employed where friable materials are being blended, and when batches as small as 15-20% of the total capacity are going to be mixed in the blender. Advantages of crb series horizontal - ribbon blenders 1- effective blade design, to achieve better mixing results. 2- available in ss or ms steel of construction. 3- capacity range from 40 ltrs to 9000 ltrs working volume. 4- available in water cooled jackets for heat sensitive products. 5- costume made solutions can be possible. 6- easy cleaning & complete drain possible due special design of blades. 7- variety of dry powders can processed with single machine. 8- blades can be changed for different types of applications. 9- can be fitted with on line with other machines to optimize the process.

...more

Double Cone Mixer

275,000 - 1,275,000 Per set

1 Set (MOQ)

As a marvelous figure in the industry, we present a wide array of Double Cone Mixer to our customers. At specific request, special purpose blenders can also be made. They can be provided with on line side feeding of liquid products for special uses. Its unique design makes the dust free working possible. Due to easy access to complete area of containers, it is very easy to clean. Basic Features Very Easy Handling of machine as well as products to be blended in it Dust Free Working possible because of Unique design Reduces time of Operations – time for loading, unloading by using spare removable container Perfect Weight loading is possible due movable container for specific / critical products. Adjustable blending time Wide range of capacity from 25 ltrs to 500 ltrs. Volume Robust Design for smooth running Very easy, fast & guaranteed cleaning possible due to easy access to complete area of containers Available in Std. & GMP models Wide Area of application – Dry Powders / wet products.

Type : Double Cone Blender

Certification : CE Certified

Weight : 100-1000kg

Color : Mulit Colour

Voltage : 220V

Condition : New

Application : Industrial Usage

Automatic Grade : Automatic

Power : 1-3kw, 3-6kw

Driven Type : Electric

Feature : Durable, Low Maintenance

...more

COPIER TONER POWDER MANUFCATURING MACHINES

Recently clarion has developed the machines to produce the Copier toner Powder. The complete et up is available from lab scale to large scale production. Please contact us for more details

...more

container mixer

875,000 Per set

1 set (MOQ)

We offer Container Mixer to our prized customers. It is a movable container mixed which is used for the purposes of mixing of powder and granular or dry materials. It processes raw material in rotary and centrifugal movement in the mixer making use of double blade system for obtainment of optimum mixing results. It is easy to clean and is leakage proof. It makes almost dust free operation possible. Basic Features Easy & clean Operation Mixing with container tumbling Reduces time for Change over & clean up Homogeneously mixing and high output No leakage and solidified particle Safe & Controlled Process thru PLC Reduces man power for material Handling Almost Dust free Operation is Possible Easy Access to Mixing blades for cleaning, changing

Capacity : 500 Ltr

Application : Industrial

Weight : 50-200kg

...moreOpening Hours