Progressive Cavity Pumps

“Indo Pump” Brand Progressive Cavity pump is a positive displacement pumps are designed principally to handle gaseous and low viscosity liquids such as Molasses. The pressure capabilities of the pump are a function of the number of cavities. These pumps are also used in food processing industries, paper industries, cement sheet industries, solvents & refineries, fertilizer industries and many other industries where viscous fluid can be easily transferred by indo pump make progressive cavity pump. Progressive Cavity pumps are available in various sizes. The pump size indicates the discharge flange bore in inches. TECHNICAL SPECIFICATIONS OF PROGRESSIVE CAVITY PUMP

...more

massecuite pumps

Introduction:- “Indo Pump” Brand zero leak Massecuite pumps are designed principally to handle high viscosity abrasive sugar products that contain sugar crystals such as Massecuite, Magma and Molasses. Rotary pump employs elliptical rotor rotating at a very slow speed in a circular casing. It is excellent for handling Magma/ Massecuite in the sugar and other highly viscous liquids like black liquor in the paper industries. The design ensures that the sugar crystals contained within the liquids are not damaged by the pumping action, and that the pump is subjected to minimum wear. Massecuite pumps are available in various sizes. The pump size indicates the discharge flange bore in inches. Principle of operation:- The pumping principle is very simple. An elliptical shaped rotor rotates in a cylindrical housing and is carried round for suction to discharge. A flap follows the surface of the rotor, scarped off the pumped medium and directs it up into discharge. Pump Features `Zero’ Leakage Pollution free. Spring less & glandless Flap Available Single Ended & Both Ended Bearing Power saver, energy efficient Gentle pumping action does not damage sugar crystals Handles, A,B,C Massecuite & magma Special, Durable & Economical mechanical seal design High pumping capacity Minimum maintenance Easy for assembly & dismantling Dynamically balanced rotor & shaft Large suction port The Pump rotors are fitted with replaceable bronze tips. Pumps are designed for either clockwise or anti-clockwise assembly Applications: “A” Magma, “B” Magma, “C” Massecuite, Dry Seed Massecuite, “B” Seed Magma, also for handling very high viscosity fluid in Sugar Industry & Food Processing.

...more

HORIZONTAL BACK PULLOUT PUMPS

DYNAMICAL BALANCING MACHINES

Easy to understand, menu driven “Windows” based software Unlimited data storage (Limited by PC Hard Disk capacity) Extensive RDBMS type database support Detailed test report/ Certificate print format Built-in balancing tolerance presetting for both balancing planes Built-in tolerance calculator as per ISO Built-in Auto Ranging and Auto tracking Filter Built-in special function to separate couple & static unbalance Simultaneous display of results for both balancing planes General Indo Pump make end drive Dynamic Balancing machines of IPHB Series are manufactured with latest state of the art technology. All Machines of this series are equipped with analog type control panel. These panels are provided with digital readout for unbalance amount angle. Construction Each model is of rigid and durable construction, reflecting the highest quality of workmanship. All electrical control and measuring system are separately housed in metal cubicle. All operating controls are conveniently arranged for safety and ease of operation .Variety of options for measuring systems are available to suit variety of rotors

...more

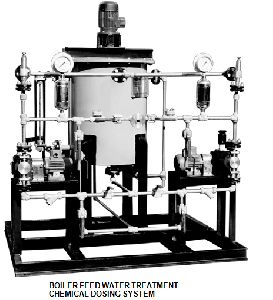

DOSING PUMPS SYSTEMS

COUPLING ALIGNMENT KIT

Alignment of rotating machinery has always been considered to be unpredictable task. To give an absolute solution to alignment problems, we have developed ‘Coupling Quick alignment kit’ which helps to complete the alignment of driver and driven equipment precisely within short period of time. SPECIFICATION This kit covers to carry out alignment of Shaft diameter from 25 to 250 mm, Distance between shaft ends (DBSE) up to 250 mm by using set dial gauges For long DBSE, two set of dial gauges can be used by mounting each set of dial gauge at each end of shaft. ACCESSORIES This kit consist of following tools for carry out alignment

...more

Centrifugal Pumps

Be first to Rate

Rate ThisOpening Hours