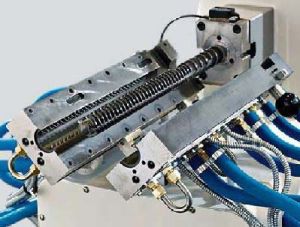

Single Screw Reciprocating Extruder (PCS 46)

Get Price Quote

Relying on our know-how in the industry gained over years, we, as a Manufacturer and Supplier of Single Screw Reciprocating Extruder (PCS 46) have put us in the top band of the industry. It can be easily cleaned in a short time span. Our customers can also save their costs as it consumes less heat and power. It also takes lesser time and energy in case of a power failure. Advantages No need of additional lab extruder for product development, shade / color matching, RM testing Easy & fast cleaning due to short length, easy & fast cooling due to water heating system Wide range of products can be produced on single screw extruder - like PU, PTFE, low curing, etc. Running cost is low as compared with Twin Screw - Low Power, Low heating cost Small batches can be easily possible Thorough cleaning is possible in small time span. Consistence product Quality possible due precise Temp Control, no problem of jamming, no problem of product deletion Low maintenance cost as compared with Twin Screw Modular design of Screw Elements to felicitate the change in kneading / feeding lengths Thru Cooling Shaft - ensures the controlled process temp. / easy cleaning of screw & avoiding deletion in the barrel. process length is much less than the Twin Screw extruder, ensures less residence time for product. machine is easy to operate If power failure occurs - takes less time / less energy for restart Due close loop heating cooling system - load on chilling gets reduced drastically Disadvantages Fine processing is limited to certain extent ( in case of rejection processing) requires extra care to be taken Spares cost is high ( but / kg cost is low as compared with twin) Thorough Cleaning is time consuming / you may need to keep spare set of Screw Shaft

LLDPE Pipe Making Machine

Get Price Quote

We are a trusted supplier of LLDPE Pipe Making Machine, providing the lucrative deals to the widespread customers at easy terms. We are capable of entertaining the urgent and bulk requirements of the customers owing to the dependable logistics facilities. Features : Sleek design Fine finish Long service life Light weight Strong construction User friendly Price : Approx. Rs 1.7 Lakh / Piece(s)

Best Deals from Plastic Extrusion Machine

monolayer blown film line

Get Price Quote

Rajoo offers widest range of customized monolayer blown film lines – foilex, to suit a broad spectrum of resins, applications and output levels. Customers opting for foilex can therefore be sure to produce best film quality with economical use of resources, short start-up and low change-over times as well as reduced waste and high productivity. Foilex - series of monolayer blown film lines are available with outputs ranging from 30 kghr to 1000 kghr and lay-flat widths ranging from 50 mm to 5000 mm for processing polymers as diverse as ld, lld, hm - hdpe, pp. Foilex – mono layer blown film lines are also available in special configurations to process hdpe rich films both through high stalk bubble and low frost line height bubbles. Foilex incorporates advanced features like-grooved feed section, barrier screw, gravimetric blendingdosing system, liquid pib dosing system, manual as well as pneumatic screen changer, oscillating haul-off, internal bubble cooling, automatic bubble cage, online thickness monitoring and control and surface winders with taper tension control.

Multilayer Blown Film Lines

Get Price Quote

We are offering multilayer blown film lines. Multifoil co-ex blown film lines are backed by proven engineering experience of rajoo for over two decades and are available in the widest range from two layer configuration for general purpose packaging film to nine layer line for barrier and technical grade films with output ranging from 120kghr to 1200 kghr and lay-flat width ranging from 600mm to 5000mm. Multifoil lines are available with advanced automation features like integrated gsm control, gravimetric blending and dosing, contactnon-contact type ibc system with pneumaticdigital correction, automatic thickness control, fully automatic center-gap-surface winder and integrated process control. A range of system solutions can be configured to adapt to the ultimate processing needs.

Cling Film Wrapping Machine

Get Price Quote

Cling Film Wrapping Machine, Strap, polythin bags

Extruder Screens

Get Price Quote

Extruder Screens, plastic flexible tube, multilayer pipes, Multilayer tube

Plastic Extrusion Machine

Get Price Quote