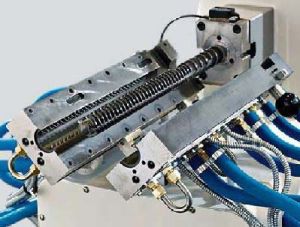

Single Screw Reciprocating Extruder (PCS 46)

225,000 Per set

1 set (MOQ)

Relying on our know-how in the industry gained over years, we, as a Manufacturer and Supplier of Single Screw Reciprocating Extruder (PCS 46) have put us in the top band of the industry. It can be easily cleaned in a short time span. Our customers can also save their costs as it consumes less heat and power. It also takes lesser time and energy in case of a power failure. Advantages No need of additional lab extruder for product development, shade / color matching, RM testing Easy & fast cleaning due to short length, easy & fast cooling due to water heating system Wide range of products can be produced on single screw extruder - like PU, PTFE, low curing, etc. Running cost is low as compared with Twin Screw - Low Power, Low heating cost Small batches can be easily possible Thorough cleaning is possible in small time span. Consistence product Quality possible due precise Temp Control, no problem of jamming, no problem of product deletion Low maintenance cost as compared with Twin Screw Modular design of Screw Elements to felicitate the change in kneading / feeding lengths Thru Cooling Shaft - ensures the controlled process temp. / easy cleaning of screw & avoiding deletion in the barrel. process length is much less than the Twin Screw extruder, ensures less residence time for product. machine is easy to operate If power failure occurs - takes less time / less energy for restart Due close loop heating cooling system - load on chilling gets reduced drastically Disadvantages Fine processing is limited to certain extent ( in case of rejection processing) requires extra care to be taken Spares cost is high ( but / kg cost is low as compared with twin) Thorough Cleaning is time consuming / you may need to keep spare set of Screw Shaft

Recycled Plastic Processing Machine

Get Price Quote

Each product in our range is made using reliable materials procured from leading vendors. Thus, our products are trustworthy. Owing to our immense expertise in this domain, we have carved a niche as a Supplier of Recycled Plastic Processing Machine in the market. Features : High efficiency Compact design User friendly operations Low maintenance Long working life Excellent finish Price : Approx. Rs 14 Lakh / Piece(s)

Best Deals from Plastic Machine

Thermoforming Machine

1,800,000 Per Set

1 Set(s) (MOQ)

weare leading manufacturer of thermoorming, vacuumfrming machines, 5-6 cnc routers, mono-multilayr extruder for pc -abs-pp

thermoforming machines

Get Price Quote

Thermoforming is a method of heating a plastic sheet and shaping it with air pressure or vacuum on a mold. It is used to manufacture parts from 0.1 to 15 mm (0.004 to 0.6 in) thick plastic sheets and finds application in the making of thin wall disposable containers like drinking glasses, cups for ice cream, yoghurt and other dairy products, disposable plates and trays, lunch/dinner boxes, jam/jelly packing cups etc. It also finds application in the making of refrigerator inners, freezer liners, airplane interiors, suitcase covers, automobile parts, bath tubs etc.Wonderpack Industries Ltd. is a leader and pioneer in the design and manufacture of Thermoforming machines. Click on the links to find out more about the range of products.

cnc small quantity abs plastic parts machining

Get Price Quote

Monolayer Blown Film Lines

Get Price Quote

We offer Monolayer Blown Film Lines. Rajoo offers widest range of customized monolayer blown film lines – FOILEX, to suit a broad spectrum of resins, applications and output levels. Customers opting for FOILEX can therefore be sure to produce best film quality with economical use of resources, short start-up and low change-over times as well as reduced waste and high productivity. FOILEX - series of monolayer blown film lines are available with outputs ranging from 30 kghr to 1000 kghr and lay-flat widths ranging from 50 mm to 5000 mm for processing polymers as diverse as LD, LLD, HM - HDPE, PP. FOILEX – mono layer blown film lines are also available in special configurations to process HDPE rich films both through high stalk bubble and low frost line height bubbles. FOILEX incorporates advanced features like-grooved feed section, barrier screw, gravimetric blendingdosing system, Liquid PIB dosing system, manual as well as pneumatic screen changer, oscillating haul-off, internal bubble cooling, automatic bubble cage, online thickness monitoring and control and surface winders with taper tension control.

plastic pouch printing machine

350,000 Per Units

monolayer blown film line

Get Price Quote

Rajoo offers widest range of customized monolayer blown film lines – foilex, to suit a broad spectrum of resins, applications and output levels. Customers opting for foilex can therefore be sure to produce best film quality with economical use of resources, short start-up and low change-over times as well as reduced waste and high productivity. Foilex - series of monolayer blown film lines are available with outputs ranging from 30 kghr to 1000 kghr and lay-flat widths ranging from 50 mm to 5000 mm for processing polymers as diverse as ld, lld, hm - hdpe, pp. Foilex – mono layer blown film lines are also available in special configurations to process hdpe rich films both through high stalk bubble and low frost line height bubbles. Foilex incorporates advanced features like-grooved feed section, barrier screw, gravimetric blendingdosing system, liquid pib dosing system, manual as well as pneumatic screen changer, oscillating haul-off, internal bubble cooling, automatic bubble cage, online thickness monitoring and control and surface winders with taper tension control.

Pet Strapping Film Machines

Get Price Quote

Pet Strapping Film Machines, Self Adhesive Cable Tie Mounts

thermoforming machines

Get Price Quote

thermoforming machines, Packaging Machines, sheet line extruders

thermoforming machines

Get Price Quote

thermoforming machines, Blister Forming Machines

thermoforming machines

Get Price Quote

thermoforming machines, blister hydraulic cutting machine

plastic molding machine

Get Price Quote

plastic molding machine, plastic component, switch gear components

plastic moulding machines

Get Price Quote

plastic moulding machines, Water Tank

Plastic Moulding Machine

Get Price Quote

Plastic Moulding Machine, jig fixture, mould bases, Plastic Moulding

PP Plastic Extruder Machine

Get Price Quote

PP Plastic Extruder Machine