Vertical Conveyors

These types of conveyors are made to carry jobs vertically upwards or vertically downwards. These conveyors can be up to 4 meters in height & can carry a load of up to 30 kgs on each pallet.

...more

Special Purpose Machine

Special Purpose Machines are manufactured as per the specific requirement of the customer. Therefore, each machine is unique in its own way and serves different purpose. Such machines improve productivity, reduce process time, and raise quality and efficiency.

...more

Slat Conveyors

Slat conveyors are conveyors which have steel slats. Slats can be of different thickness depending upon the job weight. Slats are placed very close to each other so that the job moves easily on the conveyor. Even fixtures can be welded to slats to carry different types of jobs on them.

...more

Portable Belt Sander and Horizontal Sander

Product Features: Handy to operate on site work like Home, Office, Factory. Useful to Furniture Industries for Plywood Finishing, Glass Finishing. Running on Single Phase connection, Plug and Play easy to operate. Quick changeable of Belt.

...more

lifters

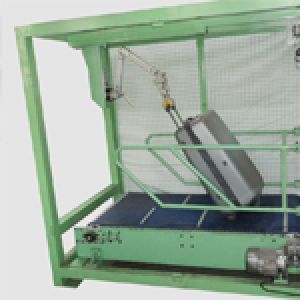

Lifters use ball screw, rail & shoe mechanism to move the job vertically upwards & downwards. Usually, lifters are used at the end of the conveyors to move the job from top line to bottom line and vice versa.

...more

Horizontal Motion Conveyor

60,000 Per Meter

Type : Horizontal Conveyor

Voltage : 230 V

Gravity Roller Conveyors

We specialise in manufacturing gravity roller conveyors. Gravity roller conveyors are made as per the specific requirement of the customers. Gravity roller conveyors are very efficient to convey the jobs. Electrical power is not required to run the gravity roller conveyors as the job moves due to gravitational force. The slope of the conveyor can be adjusted through the swivel brackets at the end. The end stopper prevents the job from falling down. Rollers can be used from mild steel, stainless steel or even PVC as per suitability. The conveyors are modular in construction, so that longer lengths are possible, using smaller modules.

...more

FIFO Racks

FIFO Racks are used to store items on First In First Out Basis. The items are stored in bins. The bins are kept one after the other. When the first bin becomes empty, the bin is to be removed. The place of the empty bin is taken over by the next filled bin. This product creates more space for storage.The largest FIFO available is 6000mm deep, and uses a crate 600mm x 400mm size. Multi tier FIFO is available.Conversion of static storage system in to FIFO is undertaken by using our Gravity Roller Tracks, which are available in two options, plain and with side guide.Special tracks for Heavy loads are also available, with Delrin material.

...more

Engine Valve Machine Linkage Automation

We are experts in automation of the machine linkages of engine valve plant. The engine valves, either Inlet or Exhaust, go through many machining processes. If the movement of valves between these machines is automated, it gives fantastic results. When the valves are transported manually between machines, the production is low; also the labour cost is high. Therefore, automation of the machine linkage definitely proves to be a profitable investment. The entire linkage starts with a vibratory bowl feeder, from which valves are fed automatically to the centerless grinding machines. The output of these machines is further fed automatically to downstream machines and so on as per the process flow.In a typical machining line between 16 to 24 machines are linked to one another, i.e. output of one machine is delivered as input to the next machine.To balance the entire line, more than one machine is employed for the given operation. Therefore output of one machine is fed to two machines as input; as well output of two machines is fed as input to one machine.

...more

Chain Conveyors

We are specialised in the manufacture of Chain Conveyors. Chain conveyors use steel chains with plastic rollers. The job has to be kept on a pallet which moves on these chains. Heavy jobs can be conveyed on chain conveyors. Therefore chain conveyors are widely used in all the industries. Chain Conveyors are very convenient to use in complicated assembly lines.

...more

Belt Conveyors

Belt Conveyors use a belt to convey the job. The choice of belt depends upon the job, weight of the job, the texture of the job, etc. Along with horizontal belt conveyors even inclined belt conveyors can be made. The properties of the belt enable it to grip the job properly & prevent the job from sliding down. There is a stainless steel sheet beneath the belt on which the belt moves.Belt widths from 50mm to 1200mm are available, for conveying components as small as 30 gms to 25 Kgs.Fixed speed or variable speeds are available.

...more

battery operated vehicle

Battery Operated Vehicle runs on dry batteries which are maintenance free. A trolley is attached to the battery operated vehicle in which the load is carried. Battery Operated Vehicle can carry a load from 100kgs to 1000kgs. Time taken to fully charge the batteries is 12 hours. Battery Operated Vehicle runs at a speed of 8 km/hour. Battery Operated Vehicle can cover a distance of 50 km in fully charged condition. Battery Operated Vehicle is supposed to run inside the factory premises. The Battery Operated Vehicle is very easy to drive, which has a very small turning radius. It can be driven by even an unskilled person, as the only controls are an accelerator and a brake, both foot pedal type. The battery operated vehicle is very economical as it runs on batteries, hence fuel is not required. Also, it is pollution free. The running cost per kilometre is much less than Rs.1/-

...more

Tool Storage Trolleys

These are trolleys in which industrial tools can be safely stored. Trolley can be made in M.S. or S.S. The drawers can slide out so that tools can be handled with ease. They also have plastic covering which makes them dust proof. Trolleys have castors so they are movable.

...moreBe first to Rate

Rate ThisOpening Hours