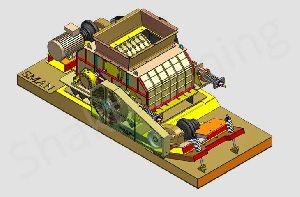

SMAN COAL DOUBLE ROLL CRUSHERS

Get Price Quote

COAL DOUBLE ROLL CRUSHER SMAN’s heavy-duty fabricated steel frame design, abrasion-resistant steel plate liners and easy-to-maintain parts means extended productive service. For maximum wear life, SMAN provides weld-on carbide teeth and can apply overlay hard facing to any applicable surface. Driven by electric motors and V-belts, all SMAN Roll Crushers have increased efficiency, high through-put for increased production and low roll speeds that minimize dust and fines. MAIN CUSTOMER BENEFITS OF DOUBLE ROLLER CRUSHER With the advanced hydraulic control system, users can adjust the pressure according to the material hardness, so that can press and pulverize the materials absolutely, with sensor, the machine can load relief when overload, so that to protect the machine; The advanced hard faced technology improves the roller Covers’ life, good performance, low cost in operation and easily maintenance. CONSTRUCTIONAL FEATURES Multistage gearbox 02 nos with fluid coupling. Double roll diameter = 1 mtr. Fitted with high manganese segment plates, which is easy for replacement. Shock impact absorbing double arrangement adjuster assembly. Heavy duty four spherical bearing with adjustment for opening in pedestal. Standard modular component easy to replace, Maintenance without any welding. This unit can be easily accommodated into any existing feeding & conveyor system.

Roll Crusher

Get Price Quote

Rolled and Electro welded Rotor made out in a single part and equipped with grinding plates, which impact the material against the suspended anvils.The two oscillating impact anvils, carrying their bars, may be regulated and fixed mechanically, depending on the adjustment which may be regulated and fixed mechanically, depending on the adjustment which may be needed. The suspension is elastic through steel springs.

Best Deals from Roll Crusher

Roll Crusher

Get Price Quote

Roll Crushers are compression type crushers, and were once widely used in mining. They have, within the last 10 or so years, fallen into dis-favor among mining and processing companies. The roll crushers are not nearly as productive as cone crushers, with respect to volume, and they do have a little higher maintenance associated with them. Roll crushers do, however, give a very close product size distribution, and if the ore is not too abrasive, they do not have high maintenance costs. Roll crushers have a theoretical MAXIMUM reduction ratio of 4:1. If a 2 inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inch. Roll crushers will only crush material down to a minimum particle size of about 10 Mesh (2 mm). A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. The gap between the rolls is set to the size of product desired, with the realization that the largest feed particle can only be 4 times the gap dimension. The particles are drawn into the gap between the rolls by their rotating motion and a friction angle formed between the rolls and the particle, called the nip angle. The two rolls force the particle between their rotating surface into the ever smaller gap area, and it fractures from the compressive forces presented by the rotating rolls. Some major advantages of roll crushers are they give a very fine product size distribution and they produce very little dust or fines. Rolls crushers are effectively used in minerals crushing where the ores are not too abrasive and they are also used in smaller scale production mining of more abrasive metal ores, such as gold. Coal is probably the largest user of roll crushers, currently, though. Coal plants will use roll crushers, either single roll or double roll, as primary crushers, reducing the ROM coal. Usually, these crushers will have teeth or raised forms on the face of the roll. (Roll crushers used for minerals and metal ores have smooth faced rolls.) Features: High capacity High reliability Easy replacement of wear and spare parts Stone broken percentage large, Cubical shape of final product Large feed opening and force-feeding action from the inward and downward eccentric movement of the swing Jaw increases capacity. Deep pitch gripper Jaws for maximum reduction. Mechanical hydraulic Jaw setting adjustment.