wheel mounted plants

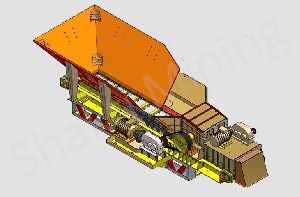

SMAN PRIMARY JAW STATIONS The SMAN Primary Jaw station utilizes a heavy-duty JAW CRUSHER capable of handling large feed sizes, possessing an appropriate angle for the crushing cavity resulting in a smooth material flow & high crushing action, material is fed to the crusher via a vibratory feeder that is fitted with a grizzly section & a by-pass chute that directs the intermediate and fine fractions to the discharge conveyor located beneath the crusher. The electrical panel is mounted on to the skid enabling easy maintenance access. The heavy duty steel fabricated skid with the optional mobile attachment reduces the need for building heavy concrete foundations & ensures quick installation & dismantling of the equipments for inter site movements. To ensure maximum operator safety and access, the operators platform has handrails and access ladder from the ground. Safety guards are fitted to the main drive and around the crushers flywheels All of these features are aimed at producing high quality aggregates, yet the simple & effective design contains many advanced features that give versatility, mobility & ease of operation.

...more

Wheel Mounted Mobile Jaw Crusher

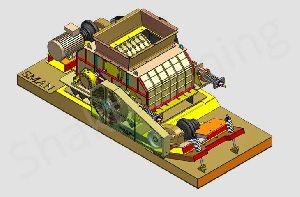

We are offering wheel mounted mobile jaw crusher. The sman mobile jaw crusher station utilizes a heavy duty jaw crusher capable of handling secondary feed sizes, possessing an appropriate angle for the crushing cavity resulting in a smooth material flow & high crushing action, a vibratory screen is further mounted on the same chassis aligning with the jaw crusher. The electrical panel & oil lubrication system is mounted on to the skid enabling easy maintenance access. The heavy duty steel fabricated skid with the mobile attachment reduces the need for building heavy concrete foundations & ensures quick installation & dismantling of the equipments for inter site movements. To ensure maximum operator safety and access, the operator’s platform has handrails and access ladder from the ground. Safety guards are fitted to the main drive and around the crushers flywheels all of these features are aimed at producing high quality aggregates, yet the simple & effective design contains many advanced features that give versatility, mobility & ease of operation.

...more

Wheel Mounted Crushing Plants

1 Piece(s) (MOQ)

We are offering sman wheel mounted plants sman primary jaw stations the sman primary jaw station utilizes a heavy duty jaw crusher capable of handling large feed sizes, possessing an appropriate angle for the crushing cavity resulting in a smooth material flow & high crushing action, material is fed to the crusher via a vibratory feeder that is fitted with a grizzly section & a by-pass chute that directs the intermediate and fine fractions to the discharge conveyor located beneath the crusher. The electrical panel is mounted on to the skid enabling easy maintenance access. The heavy duty steel fabricated skid with the optional mobile attachment reduces the need for building heavy concrete foundations & ensures quick installation & dismantling of the equipment’s for inter site movements. To ensure maximum operator safety and access, the operator’s platform has handrails and access ladder from the ground. Safety guards are fitted to the main drive and around the crusher’s flywheels all of these features are aimed at producing high quality aggregates, yet the simple & effective design contains many advanced features that give versatility, mobility & ease of operation. Sman primary jaw stations are most suitable for granite/quartzite, basalt, sandstone, iron ore & other tough and abrasive materials salient features • unique modular type jaw crusher body offering high fatigue strength • larger size bearings in jaw crusher for excellent durability • heavy steel skid including feeder & discharge conveyor for quick installation • large feed opening with a wide css range offering g.s.b. & secondary feed outputs • well equipped electrical panel • auto lubrication • optional mobile attachment for quick inter site movement • only jaw crusher without skid and accessories also available

...more

wheel mounted Cone Crusher plants

We offer wheel mounted cone crusher plants. The sman mobile jaw crusher station utilizes a heavy duty jaw crusher capable of handling secondary feed sizes, possessing an appropriate angle for the crushing cavity resulting in a smooth material flow & high crushing action, a vibratory screen is further mounted on the same chassis aligning with the jaw crusher. The electrical panel & oil lubrication system is mounted on to the skid enabling easy maintenance access. The heavy duty steel fabricated skid with the mobile attachment reduces the need for building heavy concrete foundations & ensures quick installation & dismantling of the equipments for inter site movements. To ensure maximum operator safety and access, the operator’s platform has handrails and access ladder from the ground. Safety guards are fitted to the main drive and around the crushers flywheels all of these features are aimed at producing high quality aggregates, yet the simple & effective design contains many advanced features that give versatility, mobility & ease of operation.

...more

Vibratory Screens

300,000 - 350,000 Per Piece

Type : Vibratory Screen

Material : Aluminum, Iron, Nickel, Plastic, Stainless Steel

Application : Industrial

Color : Black, Grey, Silver

Feature : Corrosion Resistance, Good Quality, High Performance, Perfect Finish

Weave Style : Plain Weave, Welded

...more

Vibratory Sand Screening Machine

"SMAN" vibratory screen machines are designed to make separation filtration of crushed material from fine dust to oversized products. The screen body assembly consists of modular type bolted frame structures along with duly welded skid and support structures reducing the need for heavy concrete foundations for installation, the Eccentric mechanism of the screen is a unique design with both mechanisms mounted on the side body plates and connected to each other by a cardon shaft arrangement in the centre fitted with heavy duty double spherical bearings with dust & water tight seals, for efficient operation and low maintenance.

...more

Vertical Shaft Impactor

1 Piece(s) (MOQ)

We are offering sman vertical shaft impactor (vsi crusher) • ready to use structure. Quick installation, immediate operation ( wheel mounted mobile option is also available ) • variable production capacity for tertiary stage material • rock on technology ensures minimum operating costs along with least wear & tear. • shape of output material is cubical & exellent for concreting • low investment. Low downtime for replacement of parts & consumables. • easy retrofit option for conversion from rock on rock to rock on metal. how it works the machine mechanism is simplified. The material to be crushed is dropped on top chute & goes through material tube on to center of closed rotor. Material from rotor gets thrown with high centrifugal force as the rotor rotates on high rpm. When this material hits inside the rock chamber assembly it gets shaped due to impact & depending on inertia of the material cubical shaped products falls freely due to gravity through the bottom chute the natural way of impact & grinding of rock on rock results in shaping the particals like natural sand making it very close natural sand. simplified retro fitment from rock on rock to rock on metal rock on rock to rock on metal version can easily converted of offering anvil rings & rocks. Chamber combination which results in higher production yield. This simplified retro fit can be easily & quickly installed on existing rock on rock model without changing the complete machine resulting in diffring products needs. tertiary stage machine suitable for ready-mix concrete artificial sand asphalt mix base material for road work

Brand Name : SMAN

Color : White

...more

Vertical Shaft Impact Crusher

Ready to use structure. Quick Installation, Immediate operation ( wheel mounted mobile option is also available ), Rock on technology ensures minimum operating costs along with least wear & tear.Low investment. Low downtime for replacement of parts & consumables.

...more

Track Mounted Screening Plants

1 Piece(s) (MOQ)

We are offering the track mounted screening plant the track mounted screening plant tms 280 represents the greatest innovation in mobile screening technology with providing larger screening areas. It is a versatile screening unit that offers the operator the capacity and ability of producing high profit graded materials at a relatively low cost it is the ultimate mobile screening equipment designed for the very serious contractors and quarry operators.tms 280 is track mounted making it mobile so that it can move itself easily to the raw material rather than the expensive movement of the material to the screen & with its massive throughput, mobility and a larger screening area the tms 280 results in the highest profit generation. Engineered for quick installation and ease of relocation along with its heavy duty steel fabricated structure tms 280 becomes a versatile machine capable of dry screening & separating a wide variety of material in the most difficult and demanding of application especially iron ore, recycling, aggregates, compost, topsoil, coal, river gravels and demolition waste. The tms 280 is perfect equipment for the quarry or recycling operation where durability, production and mobility are compulsory. salient features self propelled mobility on tracks ensures quick inter site movement wireless remote control for all major functions degree adjustable linear motion screening world class hydraulic components renowned cummins 4 cylinder turbo charged diesel engine ultra modern heavy duty chassis and structural fabrication high peed conveyor with chevron belts lowest operating cost optimum performance with minimum maintenance maximum screening area resulting in high productivity

Brand Name : SMAN

...more

track mounted screening plant

We offer track mounted screening plant. Track mounted screening plant

...more

SMAN WHEEL MOUNTED PLANTS

WHEEL MOUNTED CRUSHING PLANTS SMAN PRIMARY JAW STATIONS The SMAN Primary Jaw station utilizes a heavy-duty JAW CRUSHER capable of handling large feed sizes, possessing an appropriate angle for the crushing cavity resulting in a smooth material flow & high crushing action, material is fed to the crusher via a vibratory feeder that is fitted with a grizzly section & a by-pass chute that directs the intermediate and fine fractions to the discharge conveyor located beneath the crusher. The electrical panel is mounted on to the skid enabling easy maintenance access. The heavy duty steel fabricated skid with the optional mobile attachment reduces the need for building heavy concrete foundations & ensures quick installation & dismantling of the equipments for inter site movements. To ensure maximum operator safety and access, the operators platform has handrails and access ladder from the ground. Safety guards are fitted to the main drive and around the crushers flywheels All of these features are aimed at producing high quality aggregates, yet the simple & effective design contains many advanced features that give versatility, mobility & ease of operation. SMAN PRIMARY JAW STATIONS are most suitable for Granite/Quartzite, Basalt, Sandstone, Iron Ore & Other tough and abrasive materials SALIENT FEATURES Unique modular type Jaw Crusher body offering high fatigue strength Larger size bearings in jaw crusherfor excellent durability Heavy steel skid including feeder &discharge conveyor for quick installation Large feed opening with a wide CSS rangeoffering G.S.B. & Secondary feed outputs Well equipped electrical panel Auto lubrication Optional mobile attachment forquick inter site movement Only Jaw Crusher without skid andaccessories also available

...more

SMAN VERTICAL SHAFT IMPACTOR

Ready to use structure. Quick Installation, Immediate operation ( wheel mounted mobile option is also available ) Variable production capacity for tertiary stage material Rock on technology ensures minimum operating costs along with least wear & tear. Shape of output material is cubical & exellent for concreting Low investment. Low downtime for replacement of parts & consumables. Easy retrofit option for conversion from rock on rock to rock on metal. HOW “VERTICAL SHAFT IMPACTOR” WORKS The Machine Mechanism of vertical shaft impactor is simplified. The material to be crushed is dropped on top chute & goes through material tube on to center of closed rotor. Material from rotor gets thrown with high centrifugal force as the rotor rotates on high rpm. when this material hits inside the Rock chamber assembly it gets shaped due to impact & depending on inertia of the material cubical shaped products falls freely due to gravity through the bottom chute. The natural way of impact & grinding of Rock on Rock results in shaping the particals like natural sand making it very close natural sand. SIMPLIFIED RETRO FITMENT FROM ROCK ON ROCK TO ROCK ON METAL Rock on Rock to Rock on metal version can easily converted of offering anvil Rings & Rocks. Chamber Combination which results in higher production yield. This simplified Retro fit can be easily & quickly installed on existing Rock on Rock model without changing the complete machine resulting in diffring products needs. TERTIARY STAGE MACHINE SUITABLE FOR Ready-Mix Concrete Artificial Sand Asphalt Mix Base Material for Road Work CLICK HERE TO DOWNLOAD PDF CATALOG

...more

SMAN SAND WASHING PLANT

SMAN SAND WASHING PLANT SMAN Brand Washing Plants are the ultimate solution for washing artificial sand & aggregates. Designed as per the most advanced washing & dewatering techniques, the main body is fabricated out of mild steel plates. Heavy duty pedestal bearing for classifier & bucket rotor provide smooth radial movement. The Classifier has adjustable wiping blades so that efficient movement of the feed material can be achieved. Heavy duty gear box with electric drive provides trouble free radial movement. The washing Bucket & the dewatering screen are equipped with modular type polyurethane mesh making it last much longer & quiet easy to replace. Optional package of Hydro cyclones and Slurry Pumps also available for improved efficiently.

...more

SMAN CONE CRUSHER

SMAN SH/LH Series Gyratory Hydraulic Cone Crushers are the ultimate solution for the secondary crushing to achieve uniform product size of hard rocks, ores, stones and minerals. Depending on the required output, cone crusher is available in below models: Secondary Cone Crusher – the crushers that receives feed from the primary crusher, further reducing rock in size. Tertiary Cone Crusher – the crushers that receives feed from the secondary crusher, further reducing rock in size. Cone Crusher is suitable for the reduction of materials like rock, iron ore, gypsum, river gravel, limestone, basalt, gabbro, magnetite and also for the aggregate crushing. All bearing bushes are designed on the basis of a very well engineered metallurgic composition minimizing friction losses. The Concave and Mantle are cast out of high grade manganese steel and machined to fit the required parameters in order to achieve minimum wear and eliminate maintenance time. All Hydraulic and Rotary functions are synchronized and controlled by the hydraulic and electrical control panels. A very compact Hydraulic power pack controls all the Hydraulic and Lubrication systems. SMAN SH/LH Gyratory Hydraulic Cone Crushers are equipped with the most advanced crushing techniques. The outer shells and the other body components are made out of the finest quality steel castings and its robust design helps withstand high crushing loads. The main shaft and eccentric system is made out high grade forged alloy steel and precision machined for accurate Gyro Crushing action resulting in maintenance free operation. The heavy duty steel fabricated is fitted with a suitable discharge conveyor and electrical motor driven system making it convenient to install the whole crushing station in very short time eliminating the need to build any concrete foundation. For inter site movement mobile type skid with a foldable discharge conveyor is also available soon as option. SALIENT FEATURES Quick Installation. NO RCC foundation required Optional Mobile attachment for quick inter site movement Heavy duty skid with discharge conveyor High crushing capacities Tramp release accumulator Compact hydro-lube power pack with inbuilt safety features Uniformly in output product Heavy duty cast steel shell Electronically synchronized hydraulic & lubrication system Well equipped electrical panel with soft starter CLICK HERE TO DOWNLOAD PDF CATALOG

...more

SMAN COAL JAW CRUSHERS

COAL JAW CRUSHER A heavy duty single toggle primary jaw crusher specially designed to handle large size lumps with a specific elliptical motion crushing theory achieves the required output gradations & serves as the most economical & robust machine for coal application. SMAN Primary coal station are most suitable for crushing coal at a mine wherein there is substantial percentage of hard & abrasive rocks present in natural coal & since a jaw crusher is basically designed to handle much harder minerals & ores, crushing coal is never challenging task for such a machine

...more

SMAN COAL IMPACTORS

COAL IMPACTOR SMAN Impactor coal crushing station are the ideal choice wherein high production capacity at a minimized downtime is required. Equipped with a very heavy duty indigenously designed primary type horizontal shaft impactor fitted with dynamically balanced four blade rotor & a specially designed two stage spring loaded impact liner wall system ensures maximized crushability & productivity. SMAN Coal impactor are most suitable for crushing coal at a mine wherein hard & abrasive rock are present in a limited quantity & occasionally come through in the primary feed material. SMAN Primary impactors are designed considering such a feed & can handle it making them an ideal choice wherein high productivity is targeted.

...more

SMAN COAL FEEDER BREAKERS

COAL FEEDER BREAKER SMAN Feeder Breakers used mainly in mining of products such as coal .SMAN Feeder breakers are robust, modular and highly reliable. machine are built around a standard pool of sub systems and components to ensure a high degree of inter changeability , modular replacement , low spares and stock holding ,thus offering a very high availibity to its users . SMAN Feeder-Breakers incorporate a chain and flight drag conveyor and a rotating, horizontal pick roll to perform primary size reduction and to feed a belt conveyor or secondary crusher at a specific rate. These machines are ideal for the primary reduction of ROM coal, coke, salt, gypsum, potash and other friable minerals. Feeder-Breakers are designed with an electro-mechanical breaker drive, utilizing a torque control coupling. SALIENT FEATURES No requirement of Rcc/Ramp. Quick installation within a short period of 2 days. Width & length is suitable for normal 40 feet trailer. Feeding material can be easily feeded by loader / dumper. Mobile option is also available.

...more

SMAN COAL DOUBLE ROLL CRUSHERS

COAL DOUBLE ROLL CRUSHER SMAN’s heavy-duty fabricated steel frame design, abrasion-resistant steel plate liners and easy-to-maintain parts means extended productive service. For maximum wear life, SMAN provides weld-on carbide teeth and can apply overlay hard facing to any applicable surface. Driven by electric motors and V-belts, all SMAN Roll Crushers have increased efficiency, high through-put for increased production and low roll speeds that minimize dust and fines. MAIN CUSTOMER BENEFITS OF DOUBLE ROLLER CRUSHER With the advanced hydraulic control system, users can adjust the pressure according to the material hardness, so that can press and pulverize the materials absolutely, with sensor, the machine can load relief when overload, so that to protect the machine; The advanced hard faced technology improves the roller Covers’ life, good performance, low cost in operation and easily maintenance. CONSTRUCTIONAL FEATURES Multistage gearbox 02 nos with fluid coupling. Double roll diameter = 1 mtr. Fitted with high manganese segment plates, which is easy for replacement. Shock impact absorbing double arrangement adjuster assembly. Heavy duty four spherical bearing with adjustment for opening in pedestal. Standard modular component easy to replace, Maintenance without any welding. This unit can be easily accommodated into any existing feeding & conveyor system.

...more

Sand Washing Plant Of SMAN

SMAN Sand Making & Sand Washing Plant SMAN Shakti Mining Equipment's Private Limited is a renowned Manufacturer and Exporter of the widest range of Aggregate and minerals processing equipment mostly focusing on Crushing, Screening, Washing, Recycling and Material Handling Equipment's covering a vast spectrum in Mining & Construction Equipment field. It is based in India

...more

Sand Washing Plant

We are the leading supplier of this products.

Capacity : 50to ,50 ton

Voltage : 220 to 440

Condition : New

...more

Sand Plant

Sand Making Machine used to produce artificial sand & plaster sand; sand manufactured by crushing “Grit” The sand making machine is specially designed for manufacturing artificial sand from the grit. It is a better utilization of the large size of rock materials and stones through rock on rock metal machine mechanism roughly as follows.

...more

Sand Making Plant

Voltage : 415 V

Condition : New

sand making machines

Sand Making Machine used to produce artificial sand & plaster sand; sand manufactured by crushing “Grit” The sand making machine is specially designed for manufacturing artificial sand from the grit. It is a better utilization of the large size of rock materials and stones through rock on rock metal machine mechanism roughly as follows… WORK FLOW OF SAND MAKING MACHINE Vibrating Feeder -> Jaw Crusher -> Impact Crusher -> Vibrating Screen -> Artificial sand is a better alternative solution for natural river sand to protect the natural sand for balancing the nature and society. Nowadays construction industries are booming day by day thus artificial sand is required by construction companies for new building constructions. We offer best quality of mining equipments having higher mechanism to produce artificial sand with high productivity structure within short time span and lowest cost, which indirectly makes impact on quality of the ready mix concrete, artificial sand, asphalt mix, base material for road work. Artificial & Plaster Sand Making Machine features easy maintenance and low operating cost to increase production of artificial sand in proportion. Artificial & plaster sand making machine with constant performance, easy operation, high efficiency and easy maintenance is recently used in construction and mining industry. WHAT IS PLASTER SAND? Plaster sand is simply dust free tiny size grained sand. Mainly natural and cheapest resource of sand is river and nowadays it reducing day by day. It is crushed stones into cubical shape particles to use for ready mix concrete and base material for road work. Plaster sand is of cubical shape and it is used for construction work, concreting, plastering etc. WHAT IS ARTIFICIAL SAND? Artificial sand is tiny small grained particles which are crushed and manufactured through all stages of artificial sand making machine.Primary Level –> Secondary Level –> Tertiary level Artificial sand is better substitute for river sand, because nowadays natural river sand is not easily available, and government has also banned to drag natural sand from river bed. As per the comparison of natural & artificial sand, the maximum output result in terms of quality to sustain for long time duration is of artificial sand and it gives perfect fitness.

...more

Sand Making Machine

Artificial sand is a better alternative solution for natural river sand to protect the natural sand for balancing the nature and society. Nowadays construction industries are booming day by day thus artificial sand is required by construction companies for new building constructions. We offer best quality of mining equipments having higher mechanism to produce artificial sand with high productivity structure within short time span and lowest cost, which indirectly makes impact on quality of the ready mix concrete, artificial sand, asphalt mix, base material for road work. Artificial & Plaster Sand Making Machine features easy maintenance and low operating cost to increase production of artificial sand in proportion. Artificial & plaster sand making machine with constant performance, easy operation, high efficiency and easy maintenance is recently used in construction and mining industry.

...moreBe first to Rate

Rate ThisOpening Hours