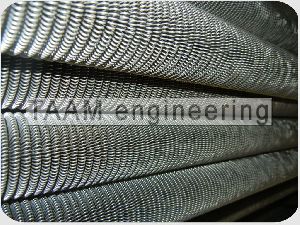

Wire Wound Turbulator Tube Inserts

We manufacture wire wound turbulators made of loops of wire wound helically on a central rod or tube and soldered to the inner surface of the tube. The internal turbulators are made of stainless steels, copper and galvanized steel wire. We make wire wound turbulators for tubes of inner diameter as low as 8 mm. There being no limit on higher daimeters and lengths.Wire wound turbulators are excellant tube heat transfer enhancement devices that increase the tube side heat transfer coefficient several fold at not too high pressure losses. Our turbulators are used in heat exchanger tubes used for oil coolers, compressed air coolers.We specialize in manufacturing all stainless steel wire turbulators and other turbulators with special composition wires. Other standard material of construction of our wire tube inserts are copper, brass and galvanised steel.

Material : Metal

Color : Grey

Feature : Rust Proof

...more

Wire Wound Soldered Turbulators

Wire wound soldered turbulators consist of rectangular loops of wire spirally wound and soldered over a solid round bar or tube. This wire wound turbulator is inserted inside tube and further soldered to the inner surface of the tube. We manufacture wire wound turbulators suitable for tube id 8 mm, there being no upper limit for tube size or length. However, maximum operating temperature should not exceed 290 C. Material of construction for wire wound turbulators being copper wire, stainless steel wire and galvanised steel wires.

...more

Wire Matrix Turbulators

Wire Matrix Turbulators consist of near oval loops of wire that can be simply pulled through the tubes as the turbulators are flexible. No soldering of the turbulator fins to tube walls is necessitated. We are manufacturers of wire matrix turbulators (flexible turbulators) suitable for tube inner diameter as low as 3 mm, there being no upper limit for tube id or length of the turbulator. The number of loops in a foot can be varied between 90 to 600 We manufacture copper wire turbulators, stainless steel wire turbulators, GI Steel wire turbulators. Manufacture of turbulators of any metal wire is possible at our works.

...more

Wire Matrix Turbulator

200 Meter (MOQ)

We manufacture wire matrix turbulators (also called Wire Petal Turbulators) for enhancing tube side coefficients in lube oil coolers, turbine oil coolers, compressed air coolers etc. We can assist clients in selecting the correct configuartion of the wire matrix turbulator to achieve required heat transfer coefficients and pressure drops.Wire matrix turbulator machine has been designed and made in India at TAAM engineering. Our special purpose wire matrix tube insert machines make wire matrix turbulators to fit in tubes and pipes having internal diameters ranging from 5.5 mm to any diameter as standard turbulators. As innovators of wire matrix turbulator making machines and wire wound finning machines, we can make turbulators to custom specifications, there being no limitation to turbulator outer diameter and length of the turbulator.Wire Matrix turbulators are very efficient tube heat transfer enhancement devices that increase the tube side heat transfer coefficient several fold. Our turbulators are used in heat exchanger tubes used for oil coolers, compressed air coolers, boiler pipes and tubes and host of other applications.

Material : Galvanised Carbon Steel (GI), SS304, SS304L, SS316, SS316L, Copper

Feature : Rust Proof

...more

Twisted Tape Turbulator

50 Kilogram (MOQ)

We manufacture twisted tape tube inserts for use in heat exchangers for enhancing the tube side heat transfer. Twisted Tape tube inserts are being manufactured to suit process requirement. Currently we manufacture twisted tape turbulators in carbon steel, aluminium and stainless steel with outer diameters from 4.1 mm to 32 mm.

Feature : Rust Proof

...more

Twisted Tape Tube Inserts

We manufacture twisted tape tube inserts for enhancing tube side heat transfer. There is no limit to the length of twisted tape turbulator. We manufacture twisted tape turbulators of all metals including: stainless steels copper carbon steel aluminum

...more

thermic fluid air heaters

Thermic Fluid heated air heaters for heating air using thermic fluids like Shell Thermia, Marlotherm, Dowtherm, Hytherm and other petroleum oils as heating medium are manufactured using root soldered wire wound fin tubes. Our designs result in economical designs coupled with low air side pressure drops.Thermic fluid air heaters made by us are being used in dryers in coated paper industry, steel strip coating and finishing lines, chemical and dye dryers.Base tubes of carbon steels, stainless steel 304, stainless steel 316 and other stainless steel grades finned with galvanised mild steel, copper and stainless steel fins are used in fabrication of air heating exchangers. The body material used so far is carbon steel and stainless steels.

Material : Carbon Steel and Stainless Steels SS304, SS304L, SS316, SS316L

Feature : Durable

...more

Thermic Fluid Cooler

The heat from exothermic reactions is sometimes removed by passing thermic fluid in coils. The hot thermic fluid has to be cooled down before sending back to the cooling coil. We design and manufacture air cooled thermic fluid coolers for such applications.

Type : Air Cooled Finned

Material : Carbon Steel, Stainless Steel with Copper, GI and Stainless Steel Fins

Warranty : 1 Year

After-Sales Service Provided : Spare Parts

...more

steam heating coils

We are offering steam heating coils for heating air for fluidized bed dryers, tray dryers etc. Steam air heaters for heating air using steam as heating medium at low to medium pressures are manufactured using finned tubes manufactured in our own factory. Our designs of finned tube heating coils result in economical designs coupled with low air side pressure drops. Flash steam can be used to pre heat the air in the flash steam to air pre-heater placed before the main live steam air heater for efficient heat recovery from flash steam. Steam coil air pre heaters (scaph) are manufactured to heat the ambient air to desired temperatures.

Material : Carbon Steel, Stainless Steel

...more

Steam Air Heaters

Steam air heaters for heating air using steam as heating medium at low to high pressures are manufactured using finned tubes manufactured in our own factory. Our designs of finned tube heating coils result in economical designs coupled with low air side pressure drops.Flash Steam can be used to pre heat the air in the flash steam to air pre-heater placed before the main live steam air heater for efficient heat recovery from flash steam.Steam Coil Air Pre Heaters (SCAPH) are manufactured to heat the ambient air to desired temperatures.Steam air heaters (steam coils, steam radiators) made by us are being used in dryers in food industries, pharmaceutical drying equipment, coated paper industry, steel strip coating and finishing lines, chemical and dye dryers.Base tubes of carbon steels, copper and copper alloys, stainless steel 304, stainless steel 316 and other stainless steel grades finned with galvanised mild steel, copper and stainless steel fins are used in fabrication of air heating exchangers. The body material used so far is carbon steel and stainless steels.

Feature : Durable, Easy Installation, Rustproof

Warranty : 1 Year

Material : Carbon Steels and Stainless Steels SS304, SS304L, SS316, SS316L

...more

Stainless Steel Wire Wound Fin Tubes

100 Meter (MOQ)

Wire Wound Finned tubes are manufactured at TAAM engineering on specially developed high speed finning machines. Our machines are capable of wire wound finning tubes in lengths up to any length as long as it can be transported. We are manufacturers of wire wound finned tubes with base tubes of carbon steels, stainless steels, copper and copper alloys like cupro-nickels, admiralty brass, aluminum brass with copper wire fins, stainless steel wire fins and GI (galvanized iron) fins. The base tubes of our standard wire wound fin tubes range from 3 mm to 120 mm with fin heights ranging from 3 mm to 40 mm. Wire Wound Fin tubing with higher fin heights can be made on demand. Wire wound fin tubes are used for making compact heat exchangers like air coolers, air cooled oil coolers, air heaters, air to air heat exchangers. Wire wound fins are formed with wire formed into a loop and the loops of wire are wound helically over the tube with simultaneous root soldering of the fins to the outer surface of the tube. The air flowing over the fin tube go round about the 'legs' of the fin loop causing immense turbulence. The root soldering eliminates almost all air gaps between the fins and the tube. This coupled with high turbulence results in high air side heat transfer coefficient. The air side heat transfer coefficient is highest as compared to any other type of fin tube for identical areas and parameters.Wire wound fin tubes for use in air cooled oil coolers are provided with internal fins selected from wide variations in configuration. We also manufacture double pipe wire wound fin tubes for use in refrigerated air dryers and heat exchangers for viscous and small streams.

...more

Spiral Edge Wound Root Soldered Fin Tubes

Spiral crimped finned tubes are manufactured at TAAM engineering on specially developed high speed finning machines. Our machines are capable of finning tubes in lengths up to 18 meters (60 feet). The fins are continuously soldered at base to the outer surface of the tube to eliminate air gaps.We make finned tubes with base tubes of carbon steels, stainless steels, copper and copper alloys like cupro-nickels, admiralty brass, aluminum brass with copper fins, stainless steel fins and GI (galvanized iron) fins. The base tubes of our standard edge wound crimped fin tubes range from 16 mm to 25.4 mm with fin heights ranging from 3 mm to 13 mm.

Type : Spiral Edge Wound Root Soldered

...more

Spiral Tension Wound Crimped Fin Tubes

Spiral crimped finned tubes are manufactured at TAAM engineering on specially developed high speed finning machines. Our machines are capable of finning tubes in lengths up to 18 meters (60 feet). We make finned tubes with base tubes of carbon steels, stainless steels, copper and copper alloys like cupro-nickels, admiralty brass, aluminum brass with copper fins, stainless steel fins and GI (galvanized iron) fins. The base tubes of our standard edge wound crimped fin tubes range from 16 mm to 25.4 mm with fin heights ranging from 3 mm to 13 mm.

Type : Spiral Tension Wound Crimped

...more

Spiral Crimped Tension Wound Fin Tubes

Spiral crimped finned tubes are manufactured at TAAM engineering on specially developed high speed finning machines. Our machines are capable of finning tubes in lengths up to 18 meters (60 feet). We make finned tubes with base tubes of carbon steels, stainless steels, copper and copper alloys like cupro-nickels, admiralty brass, aluminum brass with copper fins, stainless steel fins and GI (galvanized iron) fins. The base tubes of our standard edge wound crimped fin tubes range from 16 mm to 120 mm with fin heights ranging from 3 mm to 16 mm. We have in-house facility for surface finishing finned tubes that includes grit blasting, zinc thermal spray galvanizing, epoxy painting, HR aluminum painting, and phosphating. The finned tubes can be supplied as hot dip galvanized.

Type : Spiral

Thickness : 5-20 Mm

Certification : CE Certified

Length : 5-20 Mm

Power Source : Electric

Warranty : 1 Year

After-Sales Service Provided : Spare Part

Liquid Flow Rate : High

...more

Air Cooled Oil Cooler

TAAM engineering manufactures air cooled oil radiators (air blast oil coolers) like air cooled hydraulic oil coolers, lube oil coolers, gear oil coolers and finned tube heat exchangers to cool other viscous fluids. Typical applications are oil cooling in excavators (earth movers), compressors etc. Wire wound fin tubes with internal fins are used for making the oil cooler compact and economical.We manufacture wire wound fin tubes, turbulators and other fin tubes in our own factory. Base tubes of carbon steels, copper and copper alloys, stainless steel 304, stainless steel 316 and other stainless steel grades finned with galvanised mild steel, copper and stainless steel fins are used in fabrication of the air cooled cooler. The body material used so far is carbon steel and stainless steels.We design complete fin fan oil cooler assembly and also supply as assembled unit comprising of finned tube oil cooler, the transition piece and the fan.

Material : Copper, Steel, Stainless Steel

Certification : Iso Certified

Application : Power Generation, Hydraulic And Industrial Process, Mining & Construction Industry

Structure : Air Cooled

Warranty : 1 Year

Maximum Working Pressure : 5-20 Mpa

...more

Air Cooled Oil Cooler Radiator

TAAM engineering manufactures air cooled oil radiators (air blast oil coolers) like air cooled hydraulic oil coolers, lube oil coolers, gear oil coolers and finned tube heat exchangers to cool other viscous fluids. Typical applications are oil cooling in excavators (earth movers), compressors etc. Wire wound fin tubes with internal fins are used for making the oil cooler compact and economical.We manufacture wire wound fin tubes, turbulators and other fin tubes in our own factory. Base tubes of carbon steels, copper and copper alloys, stainless steel 304, stainless steel 316 and other stainless steel grades finned with galvanised mild steel, copper and stainless steel fins are used in fabrication of the air cooled cooler. The body material used so far is carbon steel and stainless steels.We design complete fin fan oil cooler assembly and also supply as assembled unit comprising of finned tube oil cooler, the transition piece and the fan.

Driven Type : Electric

Warranty : 1 Year

...more

Cupro Nickel Wire Wound Fin Tubes

100 Meter (MOQ)

Wire Wound Finned tubes are manufactured at TAAM engineering on specially developed high speed finning machines. Our machines are capable of wire wound finning tubes in lengths up to any length as long as it can be transported. We are manufacturers of wire wound finned tubes with base tubes of carbon steels, stainless steels, copper and copper alloys like cupro-nickels, admiralty brass, aluminum brass with copper wire fins, stainless steel wire fins and GI (galvanized iron) fins. The base tubes of our standard wire wound fin tubes range from 3 mm to 120 mm with fin heights ranging from 3 mm to 40 mm. Wire Wound Fin tubing with higher fin heights can be made on demand. Wire wound fin tubes are used for making compact heat exchangers like air coolers, air cooled oil coolers, air heaters, air to air heat exchangers. Wire wound fins are formed with wire formed into a loop and the loops of wire are wound helically over the tube with simultaneous root soldering of the fins to the outer surface of the tube. The air flowing over the fin tube go round about the 'legs' of the fin loop causing immense turbulence. The root soldering eliminates almost all air gaps between the fins and the tube. This coupled with high turbulence results in high air side heat transfer coefficient. The air side heat transfer coefficient is highest as compared to any other type of fin tube for identical areas and parameters.Wire wound fin tubes for use in air cooled oil coolers are provided with internal fins selected from wide variations in configuration. We also manufacture double pipe wire wound fin tubes for use in refrigerated air dryers and heat exchangers for viscous and small streams.

...more

Copper Wire Wound Fin Tubes

100 Meter (MOQ)

Wire Wound Finned tubes are manufactured at TAAM engineering on specially developed high speed finning machines. Our machines are capable of wire wound finning tubes in lengths up to any length as long as it can be transported. We are manufacturers of wire wound finned tubes with base tubes of carbon steels, stainless steels, copper and copper alloys like cupro-nickels, admiralty brass, aluminum brass with copper wire fins, stainless steel wire fins and GI (galvanized iron) fins. The base tubes of our standard wire wound fin tubes range from 3 mm to 120 mm with fin heights ranging from 3 mm to 40 mm. Wire Wound Fin tubing with higher fin heights can be made on demand. Wire wound fin tubes are used for making compact heat exchangers like air coolers, air cooled oil coolers, air heaters, air to air heat exchangers. Wire wound fins are formed with wire formed into a loop and the loops of wire are wound helically over the tube with simultaneous root soldering of the fins to the outer surface of the tube. The air flowing over the fin tube go round about the 'legs' of the fin loop causing immense turbulence. The root soldering eliminates almost all air gaps between the fins and the tube. This coupled with high turbulence results in high air side heat transfer coefficient. The air side heat transfer coefficient is highest as compared to any other type of fin tube for identical areas and parameters.Wire wound fin tubes for use in air cooled oil coolers are provided with internal fins selected from wide variations in configuration. We also manufacture double pipe wire wound fin tubes for use in refrigerated air dryers and heat exchangers for viscous and small streams.

...more

Air Cooled Vapor Condenser

TAAM engineering manufactures air cooled vapor condensers to condense steam and organic vapors using ambient air as the cooling medium. Wire wound fin tubes are used for making the condenser coils compact and economical. Base tubes of carbon steels, copper and copper alloys, stainless steel 304, stainless steel 316 and other stainless steel grades finned with galvanised mild steel, copper and stainless steel fins are used in fabrication of the air cooled condenser, finned tube coils. The body material used so far is carbon steel and stainless steels.

Driven Type : Electric

Warranty : 1 Year

After-Sales Service Provided : Spare Parts

Type : Air Cooled Finned

Material : Carbon Steel, Stainless Steel

...more

Air to Air Heat Exchanger

Pre heaters, heat recovery units and similar air to air heat exchangers are designed and manufactured at TAAM engineering.Hot air and gases exiting processes in industries are used as heating medium to pre heat process air by passing over finned air to air heat exchangers. Exhaust gases from fuel combustion in generators, boilers etc. is also used as heating medium. Our designs incorporate wire wound finned tubes or spiral finned tubes as dictated by the process conditions. The finned tubes have turbulators of suitable type to make the heat exchanger compact and economical.Air Cooled After-coolers and inter-coolers can be custom designed and manufactured to suit compressors.Base tubes of carbon steels, stainless steel 304, stainless steel 316 and other stainless steel grades finned with galvanised mild steel, copper and stainless steel fins are used in fabrication of air to air heat exchnagers. The body material used so far is carbon steel and stainless steels.

Material : Carbon Steel, Stainless Steels SS304, SS304L, SS316, SS316L

Weight : 100-1000kg

Grade : Superior

Voltage : 220V

Automatic Grade : Automatic

Power : 1-3kw

Warranty : 1 Year

...more

air pre heaters

Flash Steam air heaters for pre heating air using flash steam as heating medium at low pressures are manufactured using finned tubes manufactured in our own factory. The Flash Steam Air Pre Heater is placed before the Live Steam Air Heater. Preheating results in lower heat load on the live steam air heater, thereby the live steam consumption is reduced. Steam Coil Air Pre Heaters (SCAPH) are manufactured to heat the ambient air to desired temperatures. Steam air heaters (steam coils, steam radiators) made by us are being used in dryers in food industries, pharmaceutical drying equipment, coated paper industry, steel strip coating and finishing lines, chemical and dye dryers.

Material : Carbon Steel and Stainless Steel with GI and Stainless Steel Fins

Warranty : 1 Year

...more

Air Cooler and Chiller

Air coolers and chillers of the following types are designed and manufactured by us : Water cooled finned air coolers, finned air cooling coils Chilled water cooled finned tube air coolers, finned cooling coils Brine cooled finned air coolers (cooling coils) Glycol cooled air coolers (finned cooling coils) Cooling of air may be necessitated when air is being re-circulated over an equipment getting heated up during operation. Air coolers are used to cool air for cooling of large motors, alternators and generators.Air chiller is used to cool air to a temperature low enough to condense out the moisture to achieve required relative humidity suitable for use in dryers after heating the chilled air. Our designs and construction is compact and economical even where the LMTD is low.Wire wound fin tubes are used for making the finned air coolers and chillers coils. This makes these heat exchangers compact, economical with lower pressure drops. Base tubes of carbon steels, copper and copper alloys, stainless steel 304, stainless steel 316 and other stainless steel grades finned with galvanised mild steel, copper and stainless steel fins are used in fabrication of the air cooled condenser. The body material used so far is carbon steel and stainless steels.

Type : Finned

Material : Carbon Steel, Stainless Steels

Warranty : 1 Year

...more

air blast oil coolers

Air blast oil coolers like air cooled hydraulic oil coolers, lube oil coolers, gear oil coolers and finned tube heat exchangers to cool other viscous fluids. Typical applications are oil cooling in excavators (earth movers), compressors etc. Wire wound fin tubes with internal fins are used for making the oil cooler compact and economical.

Type : Air Cooled Finned

Material : Carbon Steel, Stainless Steel With Copper, GI and Stainless Steel Fins

Warranty : 1 Year

After-Sales Service Provided : Spare Parts

...moreOpening Hours