thermic fluid air heaters

Get Price Quote

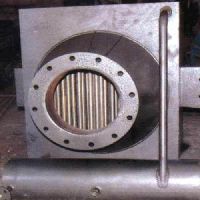

Thermic Fluid heated air heaters for heating air using thermic fluids like Shell Thermia, Marlotherm, Dowtherm, Hytherm and other petroleum oils as heating medium are manufactured using root soldered wire wound fin tubes. Our designs result in economical designs coupled with low air side pressure drops.Thermic fluid air heaters made by us are being used in dryers in coated paper industry, steel strip coating and finishing lines, chemical and dye dryers.Base tubes of carbon steels, stainless steel 304, stainless steel 316 and other stainless steel grades finned with galvanised mild steel, copper and stainless steel fins are used in fabrication of air heating exchangers. The body material used so far is carbon steel and stainless steels.

Transient Heater

Get Price Quote

We are a renowned Transient Heater Manufacturer, Exporter & Supplier in Maharashtra (India). We manufacture quality & best performance Transient Heaters for B / C Massecuites. The Transient Heaters that we offer come in 8 / 10 / 12 / 15 T/hr capacities for different types of machines. The Transient Heaters can be availed at affordable price from us. Highlights : Frequent Heating Arrangement; rises in temperature up to 8 to 10ºC when sudden feed massecuite from pug mill of centrifugal machines. In our transient heater, it may not be necessary to lift the pug mill upside (We do If require). SS 304 Tubes are skillfully Organ welded with testing at 9 Kg/cm2 has taken. Our Scope Of Supply : Transient Heater unit complete 1 No. Control system for the Transient Heater 1 Set. Vaporized Unit 1 No. Duly fabricated with Heater Details : Globe valve/ pressure relief valve / trap Air inlet globe valve Vaporizer unit duly fabricated with heater Temp. Control system (Panel, Sensor, cable and Oxilary relay)

Best Deals from Thermal Fluid Heaters

Transient Heater

Get Price Quote

In Sugar factory the massecuit going to the centrifugal machine (‘C’ massecuit in particular) should be at a specific temperature so as to minimize its viscosity and to avoid overloading of centrifugal motor. Massecuit is cooled in crystallizer to extract maximum sugar from molasses but the disadvantage of cooling is, massecuit while cooling gets more viscous, sticky & does not flow freely up to the centrifugal machine. The machine also gets ununiformly overloaded, thus it’s purging capacity reduces. To overcome all these problems there arises the need of a heater that raises the temperature of massecuit. The heater should fulfill following things. The heater design should be such that the massecuit gets heated quickly during its transit time from pug mill to centrifugal machine. If not then the problem of raise in molasses purity arises. The heater must have minimum retention time. The heater should be dimensionally small and compact so that it can be fitted above the centrifugal machine, below pug-mill. The most important is that the heater should have minimum maintenance. Heating media for the heater should be such that the co-efficient of heat transfer should be high so that the massecuit gets heated quickly during transit time through the heater. ‘VISHWA’ Transient Heater fulfills all the above points so it can be really called as ‘TRANSIENT HEATER’.Heating media in all conventional Transient Heaters is hot water. The co-efficient of heat transfer from liquid (hot water) to semi solid i.e. massecuit is very less, but that of vapour to liquid is very high. Vapours when get condensed a large amount of ‘Latent Heat’ is released. ‘VISHWA’ Transient Heater is designed, based on this phenomenon.Working Principle Self-generated low temperature vapours are used as heating media in ‘VISHWA’ Transient Heater. Input energy required to run the Heater is only about 20 Kgs. of 100 PSIG. steam per hour. Heat energy of steam is transferred to the distilled water (Condensate) filled in the part of heater called ‘Vaporizer’. Condensate in the vaporizer gets evaporated and vapours are produced. These vapours are used as heating media in the Transient Heater which circulate through S.S. tubes and get condensed again after letting out the latent heat to the massecuit.Condensate flows back in to the vaporizer and again vapours are produced. This is how massecuit heating continues in Transient Heater. The heating media loop is completely sealed and kept under vacuum to generate vapors at low temperature and heater becomes self regulating of maintenance free.Here regulating the steam supply to the vaporizer controls the vapour temperature.

Mild Steel Thermic Fluid Air Heater

Get Price Quote

thermal fluid heaters

Get Price Quote

Thermal fluid heaters are well-known for its high quality features and cost-effective prices. Materials, our fired thermic fluid heater 4-pass are accurately designed with high quality components. 4 pass vertical coil type thermic fluid heaters are in compliance with the defined quality standards. Our 4 pass vertical coil type thermic fluid heaters have robust design and rigid structure that give excellent performance.

Transient Heater

Get Price Quote

Also called asreheater is used to heat up the massecuite which just cooled down in the crystallisers. The massecuite is cooled in the crystallisers in order to grow the crystals by depositing sucrose in the mother liquor onto the crystals created in the pan. The reason to reheat the massecuite is to reduce the viscosity of the massecuite to make the separation of the crystal from the mother liquor in the centrifugal easier. If the crystallisers have been doing their work properly the massecuite will be at about 40°C. In order to be free spinning the massecuite should be heated to about 55°C. The hot water water temperature should not exceed the massecuite outlet temperature by more than 2 or 3°C. FEATURES: • Designed & Manufactured For Specific Requirement and Atomization Of Transient Heater. • Compact size No pump required as massecuite is heated by low Temperature Vapors. • Power Saving and totally Maintenance Free.

Solid Fuel Fired Thermic Fluid Heater

Get Price Quote

Solid Fuel Fired Thermic Fluid Heater Today solid fuels or agro waste as fuels is the best and low cost option for heat generation. We design, manufacture and supply Solid Fuel Fired Thermic Fluid Heater for various industrial applications from chemicals, textiles and food processing to pharmaceuticals as well. Solid fuels or agro waste can reduce the operating costs to half of the cost of fuel oils or gas. The heater design can be made suitable for below mentioned options : Coal / Indonesian coal Wood, wood chips Palm kernel shell Bagasse, briquettes Other Information Port of Dispatch: Mumbai - India Production Capacity: 10 mln Kcal-Hr