wire feeders

Wire Spool sizes: 5kg/200mm in WFX 200 and 20kg/200mm in WFX 300. Equipped with the reliable Dura Torque wire feed mechanism. WiseFusion included for ensuring consistent weld quality in all positions. Compatible with all Wise software products. Pulsed and double-pulsed MIG/MAG included. ArcVoltage feature included. It measures the actual voltage at the welding arc and displays it on the control panel. This helps you keep your welding values inside the predefined range regardless of the size and length of the cables.

...more

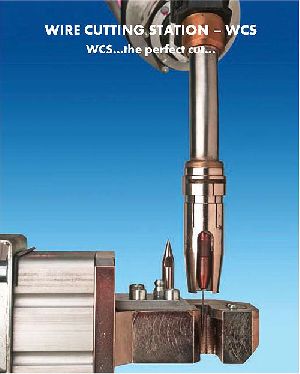

Wire Cutting Station

The ABICOR Binzel WCS Wire Cutting Station is designed to remove the ball end of the welding wire and give consistent wire stick-out. This provides superior arc starting and prevents oxidation in the weld starts. The wire cutting station will operate with all models and makes of welding robots and torches. The wire cutting station will shear up to 1/8" wire without bending. the unit clamps and holds the wire securely before shearing. The shearing blade has been tested with .045" stainless steel wire to 20,000 cuts with no disceernible wear.

...more

Welding Torch System

The ABITIG WH-Welding Torch System from ABICOR BINZEL for TIG soldering and TIG welding offers a high process stability for joining various materials. Preset tungsten electrodes, reproducible torch changes and maintenance service outside the robot cell guarantees constant high quality and continuous operation of the system. With two sizes and different geometries, the TIG welding torch system ABITIG WH covers nearly all applications in the field of automated TIG welding and is suitable for welding even the most complicated parts. Also available as Push-or Push-pull-Option with cold wire feeding. Flexible adaption on changing welding jobs Ajustable tungsten electrodes Reproducible torch position Cold wire feeding optional Liquid-cooled up to 400 A Well proven and 100% reliable

...more

welding chemicals

ABICOR Binzel has recently released a new line of welding chemicals to aid in all of your welding applications. A variety of anti-spatters and coolants including non-toxic formulas are now available. ABICOR has also added nozzle tip dip and wire lube pads to the line! Now offering : ABI-Spray - Non-flamable, paintable, aerosol anti-spatter. ABI-Shield - Water based anti-spatter. No dilution required, not affected by freezing. ABI-Mist - Water soluble, non-toxic anti-spatter specifically designed for robotic applications. ABI-Cool - Ready to use water and ethylene glycol based coolant. ABI-CoolECO - Non-toxic, propylene glycol based cooling fluid. Not regulated by OSHA or WHMIS. ABI-Gel - Nozzle tip dip anti-spatter product protects nozzles, tip, positioners and fixtures. Wire lube pads - Pretreated to reduce friction in wire feeding. Increases tip and liner life.

...more

Water-Cooled MIG Gun

The AUT750 is a cmpact, dual water-jacketed machine torch designed specifically to withstand unusually large amounts of reflected heat build-up. The two independent water cooling channels can be fed in series or in parallel by omitting the interconnecting water hose.

...more

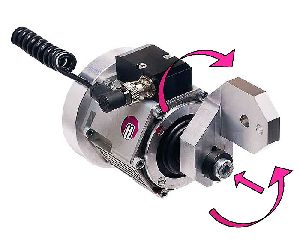

Torch Mount

Features Small in size. Lightweight. High reset accuracy. Large excursion range. Maintenance free. Compatible to any Robot.

...more

Torch Cleaning Stations

The TCS-PP "Plug and Play" torch cleaning station offers the complate solution for reliable, automatic servicing of the torch neck. Combined in a single station, the 3 point clamping system guarantees optimally timed processes and an increase in available floor space. A number of other features such as a mounting stand and drip pan reduce installation costs. Precise and effective cleaning for almost all robot welding torches. Proven and trusted cutter principle, suitable even for heavy spatter adhesion. 3-point clamping of the gase nozzle fixes the torch in place during the cleaning process.

...more

tig welding torches

The welding torch line ABITIG GRIP Little - particularly suited to those everyday, less accessible welding jobs. Maximum flexibility with no compromises. The torches of varies ratings, both air and liquid cooled, are combined with a standardized ergonomic handle with GRIP and optimised cable assembly management, into which standard switching and control functions can be integrated. All consumables are compatible to the international SR - Standarard. In addition the flexible cable assemblies are available with modular and robust machine side connections. One ergonomic handle with GRIP for all ABITIG GRIP torch types - offers high gripability and optimum feel. Modular switching and control functions integrated into the handle. Excellent protection against high frequency flashover. Light and flexible cable assemblies (High - Flex - Leather) with modular machine - side connections for all available TIG welding power sources. Consumable compatible to the international standard. Air cooled up to 140A - at 35% duty cycle. Liquid cooled up to 220A - at 100% duty cycle.

...more

TIG Automatic Welding Torches

Compact desing. Light and flexible cable assemblies for all common TIG Welding power sources. ABITIG 200MT/300W MT with pre - adjustable tungsten electoride. Especially suitable for welds at components with simple geometries.

...more

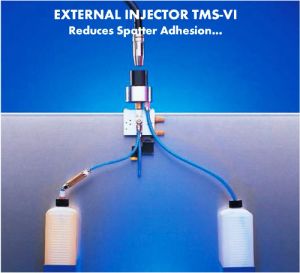

Spatter Injectors

With the external injector TMS-VI the cleaned torch is sprayed with anti-spatter fluid which minimizes build-up of welding spatter. The specially developed spray nozzel enables a highly efficient application of the anit-spatter fluid. Effective and economical anti-spatter spray supply to nozzel interior and nozzel edge. Covered injector nozzel and extra bottle for used oil improves working safety and ensures environmental friendly use. Trouble free refilling of the anti-spatter fluid simply by swapping the bottle. Trouble free disposal of used oil by swapping the bottel. Complete installation kit ready for system integration.

...more

Robotics Power Sources

Key Features KempArc is specifically designed for MIG/MAG welding automation. Synergic or pulsed welding process variants are available in either 300, 400 or 500 amp synergic models, or 350 or 450 amp pulsed models. Each range offers logical process adjustment, ensuring quick setup for busy industry. KempArc automation range allows standard or tailored weling packages to suit your specific welding enviroment. For example KempArc Pulse range offers Work Pack, including welding software selections for steel, aluminium and stainless steel filler wires or project pack where you match your specific local welding needs perfectly. Either version can be upgraded at anytime. Choose either digital or analogue models for integration with different robotic control systems. Digital process management ensures fast communication speeds for precise ignition and welding quality. Memory channels are available as standard for systems that demand independent parameter storage. Applications Robotic welding Mechanised welding Automated systems

...more

Reamer Cleaning

plasma cutting torches

Ergonomic desinged, short handle - optimal handling. Innovative trigger guard - for safe operating. Positive trigger action - comfortable functioning. Robust construction and optimal cooling - long lifetime of torch and wear parts. Contact ignition reduces costs for thermal cutting. Compatible with all popular plasma cutting power sources. Shock resistance shield cap from special material. Two stage distance shield for best for best cutting results in high and low amp area. Optional with coaxial cable. Optional in HF version.

...more

Multi-Process Welding Equipment

Applications Rolling stock & transportation Heavy machinery manufacturing Briefly Suitable for robust workshop use High quality MIG/MAG pulse welding Wise Fusion - Less faults, less repairs Save filling material - up to 30% less groove volume Reduced welding time - get it finished 30% faster MagTrac carriage compatibility - up to 5 times faster than manual welding

...more

Manual Torch Cleaning tube

Techical Describtion Operates with Hand Pressure No electrical connection and no air connection needed Fast and cost efficient cleaning of the gas nozzle Sprays even Dose of Anti-Spatter Less Wasted Product Faster than manual cleaning Operation & Installation Cutter and guiding tube are adjusted to suit the respective gas nozzle. When the torch is pushed into the opening, a rotary movement is generated on the cutter. The rotating cutter scrapes off spatter droplets from gas nozzle and contact tip. The torch cleaning unit can be mounted easily almost anywhere with only 2 clamping bolts

...more

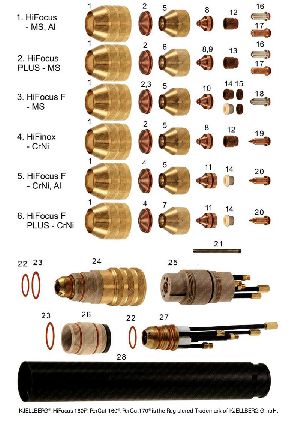

KJELLBERG

Internal Injector

The pneumatic cleaning and spray unit of ABICOR Binzel's TMS-PI is a recommended accessory for use in conjunction with ROBO welding torches and cable assemblies and is used in the automated cleaning process, providing an adjustable, measured aount of air and anti-spatter to the inside of the gas nozzel.

...more

Gouging Torch

The gouging torches TEAM BINZEL G3000 and G4000 are safe and easy to handle. They are being used for gouging, weld seam preparing, gouging out of blowholes and cracks, chamfering, cutting, surface removement and keyhole cutting for all common materials. Special features : Rugged and heat resistant handle Turnable nozzle suitable for round and lfat electrodes High air consumption High flex cable Swivel joint

...more

gouging electrodes

The TEAM BINZEL gouging electrodes are made of artificial graphite and have a pure copper coating. The gouging electrodes are available in a variety of shapes and diameters to meet the various applications. Features: Pure Copper coated - good electric coductivity. High density (made of artificial graphite) - leads to high metal removal rate. Less consumption of electrodes - cost reduction. Constant quality - for a safe process. High metal removal rate - effective process. 100% delivery guaranteed - no downtime. Extreme low burn back rate.

...more

Gas Regulator

Weld more efficiently - optimise shielding gas consumption. Optimal use of all resources is essential for an econimical and efficient welding process. However, options for optimisation of shielding gas consumption are often given too little consideration - primarily beacause of the difficulty of attributing and measuring them, as gases are not visible and tangible in the process. In co-operation with REGLA-Systems, ABICOR BINZEL offers the REGULA EWR (Electronics Welding Regulator) electronic shieding gas at the same time as providing better gas cover! Reliable, defined and verifiable. Arguments that speak for themselves : High gas saving Increased process stability Longer lifetime Reduction of the costs for handling Standardised processes Less reworking

...more

Fume Extraction Torches

Direct extraction at the arc - ensures permanent protection of the welder's respiratory system Easy installation in all existing MIC/MAG work stations Small extraction tube diameter - better accessibility Aluminium extraction tube - considerable weight saving Handle with extraction control and swivel joint - optimized handling Smaller diameter extraction hoses for all types - lower handling weight, optimum flexibility

...more

friction liner

Here we are presenting the solution with MASTERLINER the latest product of the ABICOR BINZEL Robo product range. Through an outstanding construction design in the known high BINZEL quality and a worldwide locally service and consultancy this product fulfils the high demands of our customers. Welding robots with central media guidance are spreading more and more in the international market. These special MASTERLINER can provide a solution for long distance wire feeding application with elimination of use of multiple wire feeders Application Connecting bulk-wire system with wire feeder. Connecting bulk-wire system with MF1-Master Pull or MF2-Laser feeder. Advantages No abrasion due to extremely small forces on the wire. No maintenance necessary. Excellent feeding of soft wires. Reduced cost due to the reduction to one wire drive only (Master Pull System). Stable arc due to precise wire feeding. Simplified setup of welding systems due to more freedom in situating the bulk-wire system. Rolliner NG can easily be made longer or shorter. Suitable for all wire types. With ROLLINER NG feeding occurs through rolls only, shifted by 90� - without any sliding friction.

...more

FastMig X Regular Welding Machine

coolant recirculator

The portable cooling device for all common applications! Simple handling : Connection (feed and return) via quick-action couplings. Compact design size : Small space requirments. Sturdy design : Indestructible stainless steel tank and sturdy housing. Service-friendly : Clear coolant sight glass.

...moreBe first to Rate

Rate ThisOpening Hours