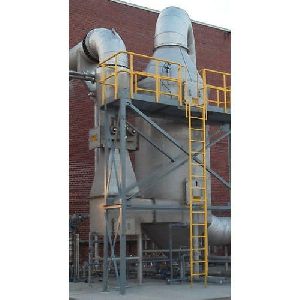

Venturi Type Scrubber

Brand Name : Ankita

Driven Type : Electric

Power : 35 kW

Voltage : 220 V/50 Hz

...more

Venturi Scrubber

we have come up with a wide range of venturi scrubber. With the support of s sincere team of professionals, we manufacture the entire offered range as per the industry set quality parameters. Adhering our quality policy, we dispatch all the products after being stringently examined by our quality controllers team

...more

Spray Dryer

Our range of Spray Dryers is one of the most economical methods of evaporation to reduce a liquid feed to solid powder particles. The use of powder in these products facilitates in offering versatile methods of preservation and cost effective in both storage and transportation of finished goods. Furthermore, our range is widely used in all types of industries, where various products are in need of specialist designs and finishes to maximize the efficiency or sanitary needs of that particular process. Spray dryers are offered for feeds in liquid form containing either water or any other solvent. Feeds may be solution, slurry or emulsion. Depending on the particle size of the final product required and the nature of feed any one or combination of following atomization system is used. Other Details: Two fluid atomization. High pressure single fluid atomization. Rotary disc atomization. The final product obtained from spray dryer is in powder form. By varying the operating parameters of the spray dryer the required powder characteristics such as moisture, particle size, bulk density, flow ability, Particle Morphology etc. can be achieved. Besides manual and semi-automatic systems we offer PLC & SCADA based systems for easy operation and monitoring of spray dryer. Multiple systems can be operated from a single computer thus reducing the manpower requirement. All the important parameters like temperatures, pressures, flow etc. are recorded and displayed in the system and can be retrieved at any given moment. Capacity: The spray dryers having water evaporation capacity ranging from 1kg/hr to 18,000 kg/hr can be offered and supplied.

...more

spin flash dryers

To fulfill the divergent needs of our valued clients, we are betrothed in offering Spin Flash Dryers. Use for continuous drying of cohesive and non-cohesive pastes, these dryers are Pramoted by using supreme quality material & coated with powder from feed, which is viscous. Offered dryers are highly applauded for its flawless range. We are giving these dryers to our patrons in customized options. Features: Require less maintenance Easy to operate High efficiency Other Details: Function and principle of operation Spin Flash dryers are designed for continuous drying of cohesive and non-cohesive pastes and filter cakes, as well as high-viscosity liquids The main components in a complete Spin Flash Drying System are a feed system, drying chamber, bag filler and Exhaust Blower The feed system consists of a feed vat where a discontinuous flow of product is buffered and fragmented by an agitator prior to continuous drying A variable speed feed screw (or pump in the case of fluid feed) forwards the product to the drying chamber Drying chamber The disintegrater at the base of the drying chamber fluidizes product particles in a drying-efficient hot air flow pattern in which any wet lumps are rapidly disintegrated Hot air is supplied by a temperature-controlled air heater and speed-controlled fan, entering the drying chamber at a tangent in order to establish a turbulent, whirling air flow Airborne, fine particles pass through a classifier at the top of the drying chamber, while larger particles remain in the air flow for further drying and powdering The drying chamber is rigidly designed to withstand pressure shock in the event of explosive combustion of flammable particles All bearings are effectively protected against dust and heat Bag filter Powder from the drying chamber is collected in a bag filler, while the outlet air leaves the system at the top via a suction fan

...more

Side Stream Filter

We have positioned ourselves as a renowned manufacturer and supplier of excellent quality Side Stream Filter

...more

Sand Filter

With our expertise in this domain, we are offering our valued customers with a wide range of Sand Water Filter. These products are widely used in homes, distilleries and food and beverage industries as they are best known for their quality filtration and superior quality water. We offer all our filters at unmatched market prices so that our customer will be maximum benifited. Features: Easily settable impurities Floating impurities Suspended impurities

...more

Rotary Vacuum Dryer

Rotary Vacuum Dryer offer clean, simple and effective method of drying wet cake, powder and even slurry. Labor and energy costs are minimal compared to tray dryers and product losses during handling are also negligible. Additionally valuable organic solvents can be conveniently condensed and recovered. Working PrincipleThe drying in a rotary vacuum dryer is a batch operation under vacuum. It is possible to dry heat sensitive materials at well below boiling points of water and solvents. Drying time depends on material being dried, amount of solvent or water to be removed, desired final moisture content, permissible jacket temperature etc. The dryer is available in sizes ranging from 100 liters to 20,000 liters gross volume. The volume of wet material loaded into the dryer is usually restricted to 40-45% of gross volume.Salient Features Equipped with different designs of agitators depending on the material to be dried. Unique quick opening discharge valve permits direct packing of dry product into bags or drums. Breaker rods are provided to prevent lump formation and allow quick and complete drying. Shaft sealing by mechanical seals is also available. N2 pulse jet dust filter (self cleaning type).

...more

Rotary Evaporator

We are supplier and exporter of this product.

Material : As per requirement

Brand Name : Ankita

Voltage : 220 V

...more

Rotary Calciner

2,200,000 Per

Brand Name : Ankita Technologies

Polished Heat Exchanger

65,000 Per Piece

Application : Chemical, Food, Agro, Pharma Industry

Type : As per requirement

Brand Name : Ankita

Medium used : As per requirement

Material : Stainless Steel, M.S., Alloy etc

Automatic Grade : Automatic

Condition : New

...more

Packed Bed Scrubbers

By keeping track with the market development, we are engaged in providing our clients with excellent quality Packed Bed Scrubbers.These scrubbers are developed by using supreme quality material & modern techniques. Offered scrubbers are highly applauded for its flawless range. We are giving these scrubbers to our patrons in customized options. Features: Precisely engineered Smooth functioning Noiseless operation

...more

horizontal leaf filter

As compared to other continuous filtration processes, Horizontal Pressure Leaf Filter offer simplicity of process, easy operation and maintenance, modest space requirement low energy consumption and low capital outlay.

...more

fluidized bed dryer

In Fluidized Bed Dryer, the process air is supplied to the bed through a special perforated distributor plate and flows through the bed of solids at a velocity sufficient to support the weight of particles in a fluidized state. Bubbles form and collapse within the fluidized bed of material, promoting intense particle movement. In this state, the solids behave like a free flowing boiling liquid. Advanced method of drying wet/semi wet solids Unlike in Tray Drying every solid particle is floating in the HOT STREAM of Air which is blown from down to up creating material layer in fluidized state Almost every wet particle directly receives the heat energy from hot Air resulting in uniform and quick drying

...more

Drum Flaker

Backed by the years of experience in this domain, we are passionately engaged in offering optimum quality Drum Flaker. It does not require the use of manpower; our offered drum flaker is designed by our professionals by using finest components as per the set guidelines. In addition to this, we offer this drum flaker in various specifications and can be further customized on demand. Offered drum flaker is demanded in the market for its performance.Features: Easy to maintain High functionality Precisely engineered

...more

Drum Dryer

Riding on unfathomable volumes of industrial expertise, we are engaged in providing premium quality Drum Dryer. This dryer is used for pigment colors, insecticides, pesticide, minerals & ores. Our dryer is designed in accordance with international quality standards by using top grade material and advance technology. This dryer is checked in terms of quality for delivering a flawless range.Features: Low power consumption Reliable functioning High performance

...more

Bagasse Dryer

We have positioned ourselves as a renowned manufacturer and supplier of excellent quality Bagasse Dryer which is used to reduce moisture content of bagasse, the offered dryer is Pramoted by utilizing the finest grade components and advance technology in adherence with the set industry standards. Along with that, the offered dryer can also be availed from us in customized options at market leading prices.Features: Easy to operate Rigid design Long functional life

...more

Bag Filter

Bag Filters are used for the recovery of particulate matter from exhaust gas which enables to: Avoid pollution problems Recover finished product thus increasing plant yield Apart for bag filters other equipments such as cyclones, venturi, scrubbers, electrostatic precipitates etc. can be used for the recovery of particulate matter. However, out of all these equipments bag filter becomes the best choice under the following circumstances: The final product is very expensive and as a result high collection efficiency is required. The particulate size is very fine.

...more

Automatic Rotary Dryer

2,200,000 Per Piece

Brand Name : Ankita Technologies (I) Pvt. Ltd.

Agitated Nutsche Filter

Being a quality conscious organization, we are providing our client’s best quality gamut of Agitated Nutsche Filter which is a closed vessel designed to separate solid and liquid, the offered nutsche filter is developed by utilizing the finest grade components and advance technology in adherence with the set industry standards. Along with that, the offered nutsche filter can also be availed from us in customized options at market leading prices.Features: Fully automatic Energy efficient Proper functioning Other Details: The Agitated Nutsche Filter consists of a cylindrical shell with top dished and welded flat bottom The base plate is stiffened by supports welded under the base plate The base plate is having arrangement of bolting bar to hold the filter cloth Suitable support mesh is provided under filter cloth to facilitate the flow of filtrate Suitable nozzles are provided including Manhole and Side discharge nozzle Solid bar is used for Agitator shaft and solid plate for blades made in specially “S” curved to take high torque generated during solid discharge and re-slurring operation The unit consists of a totally enclosed and sealed cylindrical shell fitted with a agitator assembly which moves horizontally as well as vertically The cylinder operates under pressure or vacuum or both A filter plate with filter cloth is fitted at the bottom of the shell for separating liquids from solids The cake is retained on top of the plate The upward and downward movement of the agitator assembly is utilised for cake washing, compressing, drying and discharge of the cake A vacuum pump connected to receiver is installed for discharging of liquids and vapour collection The cylindrical shell can also be provided with a jacket

...more

Activated Carbon Filter

Innovation is our forte and we strive to design and develop a precision engineered range of Activated Carbon Filters. All these filters are designed in order to remove color, odor and bad taste from the water. These filters treat activated carbon with oxygen traps the particles and adsorbs other impurities from the flowing stream of water. Offered range of carbon filters are highly effective in removing chlorine, sediment, and volatile organic compounds (VOCs). To attract the impurities, the vast area of activated charcoal gives these filters countless bonding sites. We also offer these filters in custom-built range and at market leading prices

...more

Rotary Vacuum Drum Filter

We are prominent and trustworthy manufacturer and supplier of top quality range of Rotary Vacuum Drum Filter. This drum filter is manufactured using highly advance techniques & quality material for fulfill the requirements of our customers. Also, our offered drum filter provides operating flexibility to handle dewatering, washing. Customers can avail this drum filter from us at competitive rates. Features: Ease of use Precisely engineered Hassle-free functioning Other Details:Drum: The drum is supported by a large diameter trunion on the valve end and a bearing on the drive end The drum face is divided into circumferential sectors each forming a separate vacuum cell The internal piping that is connected to each sector passes through the trunion and ends up with a wear plate having ports that correspond to the number of sectors Valve: A valve with a bridge setting controls the sequence of the cycle so that each sector is subjected to vacuum, blow and a dead zone When a sector enters submergence vacuum commences and continues through washing, if required, to a point that it is cut-off and blow takes place to assist in discharging the cake The valve has on certain filters adjustable blocks and on others a fixed bridge ring Adjustable bridge blocks enable the optimization of form to dry ratio within the filtration cycle as well as the "effective submergence" of the drum when the slurry level in the tank is at the maximum The majority of drum filters have a valve with three bridge blocks and a single row pipe plate as shown below and on the right The duty of the bridges is: Vacuum and blow zones separating bridge. This bridge cuts off the vacuum so it is slightly wider than the internal pipe port Dead zone bridge: This bridge opens to vacuum once a compartment submerges Start-up assist bridge: At start-up the upper vacuum zone is open to atmosphere and a cake may be formed only when closing the valve that controls this zone Once the cake starts to emerge from the tank the valve is gradually opened and fully opened when the entire drum face is wrapped with the cake Since in continuous operation both lower and upper zones are under vacuum this bridge is slightly narrower than the internal pipe port so that the vacuum is continuous and the cake is held onto the drum

...more

Pneumatic Conveyor System

Distillation Column

titanium reactor

Detailed Engineering Service

Be first to Rate

Rate ThisOpening Hours