Bakery Continuous Mixer

Get Price Quote

The Continuous Mixer is used for mixing hard dough and soft dough for cookies and tea biscuits. It is an automatic mixer that supports continuous production of various bakery products. The mixer operates with gravimetric / volumetric / incremental dosing through pre-mixing /creaming to the final mixing. The mixer runs on continuous feeding system. Components :- Pre-creaming section Cream holding/dozing section Flour dosing section Main mixing chamber Conveyor section. Advantages :- Reduction in manpower and wastage of packaging material Savings in power & fuel consumption and in cost of dough production No standing time for dough Improvement in hard/soft biscuit (cookies), bread, asian chapatti, tortilla Reduction in line weight variation and expensive ingredients such as fat, sugar, chemicals, rising agent Minimum dough wastage Increase in productivity, packing efficiency and biscuit stack height Instant start and stop of the plant is possible Reduction in floor space and building investment Skid mounted systems reduces installation and commissioning time Trouble free and smooth operation results in stress free supervision. Applications :- Agro Industry (Fertilizers, pesticides, etc.) Plastic Industry (Premix and dosing for plastic extrusion) Chemical Industry (For polymerization reaction and condensation reaction) Adhesive Industry (Manufacturing sealing compounds, Dough for putty adhesive) Paint Industry (Premix) Cement Industry (Pre-blending of dry powders) Pharmaceutical Industry (Formulation of ointments, creams and gels).

atta maker machine

20,097 Per Piece

01 Piece(s) (MOQ)

Best Deals from Dough Mixers

Concrete Planetary Mixer

Get Price Quote

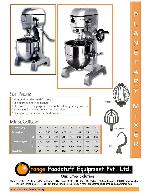

Planetary Mixers

Get Price Quote

Application(For dry & Dough Mixing): Planetary mixers are an ideal mixer for the products of different viscosities, densities, shapes & proportions. The major uses include the production of latexes, dispersion & micro – dispersion of Chemicals, Explosive & agricultural pesticide formulations. It is suitable for mixing / blending powders as well as through mixing of ointments, creams, lotions, toothpastes, resins, slurries, ceramics, colors, pigments, rubber & other compounds. Working Principle Planetary Mixers Planetary mixers consist of a single or double blade with a high speed dispersion blade (Emulsifier / Homogenizer). Intimate & homogeneous mixing of products is achieved by planetary motion of beaters & centrally located high speed dispersion blade for vacuum jacketed mixer units. The PLM consists of two open beaters moving in planetary motion, scraper blade & centrally located high speed homogenizer run by a separate motor to manufacture ointments. creams. suspensions etc. Emulsifier / Homogenizer It is a stator-rotor High shear. High speed, & high power mixer are the main characteristics of this stator-rotor mixing device. The high shear action creates a forced product flow. The interchangeability of homogenizer blades is possible to suit the mixing requirements of various products. They are used in many process operations like Homogenization, Dispersion, Emulsification, Grinding , Dissolving, Chemical reaction, Cell disruption & Coagulation. Our Specialities Creating innovative and cost effective designs as per your requirement to give you maximum and best output from our equipment Providing Lab Models in exactly the same material to give the accurate results Design and supply of entire turnkey projects at any scale, from 500 kgs to 20,000 kgs capacities. Salient Features Provision to mix Products under vacuum for de-aeration purpose. Teflon scrappers are provided to avoid localized heating or cooling & ensure uniform mixing. Top drive & agitator assembly can be lifted & lowered by motorized as well as hydraulic systems. Smaller version of planetary Mixer is Provided with a manual lifting arrangement for the bowl instead of top drive & agitator assembly. Pneumatic system is also available for lifting & lowering top drive & agitator assembly for smaller version of Planetary Mixers. Different designs of beaters are available to suit the mixing requirements of wide variety of materials. The laboratory model of the PLM mixer with Homogenizer is also available in batch sizes of 2 litres to 5 litres with various types of mixing blades. Promas Age Over The Other Manufacturer, supplier and exporter of planetary mixers including single and double blades since 1990 from Mumbai to India and entire world. Promas engineers is approved by Indian Defence ordnance factories and explosive chemicals manufacturer industries. For discharge of high viscous material plunger systems is provided. PLM WITH SCRAPEER PLM LAB MODEL 5 Litres PLM PLUNGER SYSTEM

Planetary mixer

Get Price Quote

1 Piece(s) (MOQ)

Used for mixing dough for Cake, Cream, etc Available from 5 Lts to 80 Lts capacity

Planetary Blender

Get Price Quote

Planetary mixers consist of a single or double blade with a high speed dispersion blade (Emulsifier Homogenizer). Intimate & homogeneous mixing of products is achieved by planetary motion of beaters & centrally located high speed dispersion blade for vacuum jacketed mixer units. The PLM consists of two open beaters moving in planetary motion, scraper blade & centrally located high speed homogenizer run by a separate motor to manufacture ointments. creams. suspensions etc.

Planetary Mixers

Get Price Quote

Capacity: 3 litres to 2500 litres Application(For dry & Dough Mixing): Planetary mixers are an ideal mixer for the products of different viscosities, densities, shapes & proportions. The major uses include the production of latexes, dispersion & micro – dispersion of Chemicals, Explosive & agricultural pesticide formulations. It is suitable for mixing / blending powders as well as through mixing of ointments, creams, lotions, toothpastes, resins, slurries, ceramics, colors, pigments, rubber & other compounds. Working Principle Planetary Mixers Planetary mixers consist of a single or double blade with a high speed dispersion blade (Emulsifier / Homogenizer). Intimate & homogeneous mixing of products is achieved by planetary motion of beaters & centrally located high speed dispersion blade for vacuum jacketed mixer units. The PLM consists of two open beaters moving in planetary motion, scraper blade & centrally located high speed homogenizer run by a separate motor to manufacture ointments. creams. suspensions etc. Emulsifier / Homogenizer It is a stator-rotor High shear. High speed, & high power mixer are the main characteristics of this stator-rotor mixing device. The high shear action creates a forced product flow. The interchangeability of homogenizer blades is possible to suit the mixing requirements of various products. They are used in many process operations like Homogenization, Dispersion, Emulsification, Grinding , Dissolving, Chemical reaction, Cell disruption & Coagulation. Salient Features Provision to mix Products under vacuum for de-aeration purpose. Teflon scrappers are provided to avoid localized heating or cooling & ensure uniform mixing. Top drive & agitator assembly can be lifted & lowered by motorized as well as hydraulic systems. Smaller version of planetary Mixer is Provided with a manual lifting arrangement for the bowl instead of top drive & agitator assembly. Pneumatic system is also available for lifting & lowering top drive & agitator assembly for smaller version of Planetary Mixers. Different designs of beaters are available to suit the mixing requirements of wide variety of materials. The laboratory model of the PLM mixer with Homogenizer is also available in batch sizes of 2 litres to 5 litres with various types of mixing blades. Promas Age Over The Other Manufacturer, supplier and exporter of planetary mixers including single and double blades since 1990 from Mumbai to India and entire world. Promas engineers is approved by Indian Defence ordnance factories and explosive chemicals manufacturer industries. For discharge of high viscous material plunger systems is provided. PLM WITH SCRAPEER PLM LAB MODEL 5 Litres PLM PLUNGER SYSTEM

dough divider machine

350,000 Per

spiral mixer

55,000 Per Piece

Planetary mixer

Get Price Quote

The major uses include the production of latexes, dispersion & micro � dispersion of chemicals, explosive & agricultural pesticide formulations. It is suitable for mixing blending powders as well as through mixing of ointments, creams, lotions, toothpastes, resins, slurries, ceramics, colors, pigments, rubber & other compounds

dough moulder

Get Price Quote

We are offering a wide range of finest quality dough moulder from india.

bakery mixers

Get Price Quote

bakery mixers, Bakery Equipments, Counters, Wet Grinders, Vegetable Cutter

Planetary Mixers

Get Price Quote

we are offering planetary mixers. we are engaged in to the manufacturing and exporting of superior quality of planetary mixers, fabricated from finest quality of raw materials using latest machines and advanced technology. our range of planetary mixer is widely used in manufacturing of personal care & cleansing products, adhesive, dispersion and micro-dispersion of chemical & agricultural pesticide formulations and many others.

Rubber Mixer

Get Price Quote

Rubber Mixer, rubber process machinery

Dough Kneader

Get Price Quote

Dough Kneader, Planetary mixer, Rotary Oven, Dough Sheeter

spiral mixer

Get Price Quote

spiral mixer, Almonard Industrial Air Circulation Fan, commercial dishwasher

Planetary mixer

Get Price Quote

Planetary mixer, Rotary Cone Vacuum Dryers, Colloid Mill

spiral mixer

Get Price Quote

spiral mixer, Panipuri Making Machine, Masala Roaster Machine

Planetary mixer

Get Price Quote

Planetary mixer, Heat Exchanger, Used Chemical Machinery, Centrifugal Dryer