Vacuum Tray Dryer

206,000 Per

Tray Dryer

Get Price Quote

Ribbon blender/powder mixer mixes in 5minot 50100/25/500/1200kf ready

Best Deals from Dryer Machine

rotary vacuum dryers

Get Price Quote

RVD's have a wide range of application in pharmaceutical, dyes/dye intermediates, inorganic chemicals, agrochemicals, organic chemicals, and other allied industries. We manufacture agitated RVD with or without internally heated shaft, depending upon the heat transfer requirements. We manufacture RVD's with external heating both through jacket/limpet coils. The scrapper plates provided scraps almost 100% of the inner surface of the shell to ensure efficient separation. The discharge valve and charging doors may be both manual and pneumatic/hydraulic type. They are provided with either mechanical steels of stuffing box depending upon the applications.

Refrigerated Air Dryer

Get Price Quote

Our Air dryers are a high efficiency cooling module. They are energy efficient and prevent pressure drop. Features : CFC free, Eco friendly refrigerant used in system. Tube in tube type evaporator. Designed to prevent the formation of ice inside the evaporator. No maintenance required. Gives high degree of moisture separation. Compact design, requires less floor space. Available Range from 15 CFM to 3000 cfm. Capable to work up to inlet air temperature of 60˚C. Can work up to a compressed air pressure of 40 bar.

Ingersoll-Rand Evolution Refrigerant Air Dryer

40,000 - 200,000 Per Piece

1 Piece (MOQ)

FEATURES : 3 in 1 Heat exchanger Evolution design – specifically for the application Engineered for a low pressure drop Robust aluminum construction reduces corrosion Stainless steel demister ensures moisture removal Advanced Controls Full feature, multi function control panel Energy saving mode – shuts dryer off during low loads Alarm display High and very high dew point Low dew point Probe failure Fan speed indication Remote alarm contact

radio frequency dryer

2,200,000 Per

1 Piece (MOQ)

High Pressure Nitrogen Dryer (-) 80 to (-)110 Deg.C

Get Price Quote

1 Unit (MOQ)

paint dryers

Get Price Quote

Cooling tunnels maybe fabricated – two blowers force ambient or outside air in while drawing the heated air from the parts out the opposite end. Simply passing air over a part results in significantly faster cooling. Why you need paint spray booth ? LAW : There is a statutory requirement under the Factories Act that adequate ventilation be installed wherever spray painting is carried out. SAFETY : Spraying paint may involve fire risk from both solvent and overspray deposits. A spray booth is essential to dispose off both.

Desiccant Dryer

700,000 Per Unit

agitated vacuum dryer

Get Price Quote

We are manufacturer, supplier and exporter of agitated vacuum dryers according to isi guidelines and user’s requirements since 1990 from mumbai to india and all over the world.

Fluid Bed Dryer TG 200

Get Price Quote

The fluid bed dryer TG 200 is used in quality control, sample preparation and R&D departments. It permits the gentle drying of organic, inorganic, chemical or pharmaceutical bulk materials without localized overheating. Suitable materials can be coarse, fine, crystalline, fibrous or leafy. The powerful fan of the fluid bed dryer ensures optimal air throughput so that the products to be dried are loosened up and thoroughly mixed resulting in short drying times. With the interval operation the fluidized bed is mixed even better. Temperature, drying time and air volume can be set digitally and adjusted continuously.

Rotary Dryers

Get Price Quote

Rotary dryers, Low temperature drying under vacuum, Specially designed micro air-filter can be provided on receiver while breaking vacuum for safety operation, Specially designed S.S. Rotary union is provided for hot water or steam at inlet & outlet, Direct drive with hollow shaft gear to suit cGMP operation & to avoid greasing of the gear.

fluidized bed dryer

Get Price Quote

In Fluidized Bed Dryer, the process air is supplied to the bed through a special perforated distributor plate and flows through the bed of solids at a velocity sufficient to support the weight of particles in a fluidized state. Bubbles form and collapse within the fluidized bed of material, promoting intense particle movement. In this state, the solids behave like a free flowing boiling liquid. Advanced method of drying wet/semi wet solids Unlike in Tray Drying every solid particle is floating in the HOT STREAM of Air which is blown from down to up creating material layer in fluidized state Almost every wet particle directly receives the heat energy from hot Air resulting in uniform and quick drying

Tray Dryer

80,000 Per Units

agitated vacuum dryer

Get Price Quote

We are manufacturer, supplier and exporter of agitated vacuum dryers according to ISI guidelines and user’s requirements since 1990 from Mumbai to India and all over the world. Application: To dry heat sensitive and air sensitive material under vacuum thus accomplishing the drying at moderate temperature avoiding contact with air. Working Principle Agitated Vacuum Dryers The entire drying chamber is well machined to bring about a close encounter with the agitator blade thus ensuring proper shuffling of the material and thus avoiding localised over heating. The leak proof front opening door ensures easy cleaning of the entire chamber. The top loading and bottom unloading facility provides for easy charging and discharging of the material. The cyclonic trap prevents the fine dust of the dry material from flying into the vapour condenser. The condenser and the condensate collection tank prevent the vapours from entering the vacuum pump. Appropriate vacuum pump and accessories are provided with the unit with valves to adjust the right vacuum in the unit. The entire unit is mounted on a steel frame. Our Specialities Creating innovative and cost effective designs as per your requirement to give you maximum and best output from our equipment Providing Lab Models in exactly the same material to give the accurate results Design and supply of entire turnkey projects at any scale, from 500 kgs to 20,000 kgs capacities. They are used with particular success in agglomeration free rapid drying, heterogeneous reactions with systems of different substances, sterilization and in general for vacuum application. Heating arrangement can also be provided along with the unit. Choice of product contact materials: AISI 304L, AISI 316L, Hastelloy optional HALAR/PTFE Coating available. Volume of the wet material loaded into the dryer is restricted to 40-45 % of gross volume. Salient Features Fast dry product discharge :- Dried material is discharged quickly by pushing action of the blade towards the discharge valve Large size front door allows full accessibility for easy and thorough inner cleaning Full door opening & Dismantable blade, not in hollow blade d,esign helps for Cleaning / Validation Standard manufacturing high geometric accuracy of the body surface ensuring efficient removal of the product from the heated walls Full process automation possible by means of PLC & DCS (* Optional) Internal heating is through a hollow shalf. The blades are provided with scrappers with minimum clearance versus heated wall which increases the rate of heat transfer. It is possible to install the dryer through a partition wall separating its loading unloading connections from its drive assembly, vacuum system water heating system etc. High speed chopper contributes to the drying process

Fluid Bed Dryer

Get Price Quote

Fluid Bed Processing involves fast drying, cooling and agglomeration of particulate materials. It is ideal for heat sensitive and non heat sensitive products in Pharmaceuticals, Chemicals and Biochemical, Food and Dairy Industries. The Fluid Bed Dryer have a bed of solid particles which are fluidized by passing a stream of air upward through a specially designed perforated sheet. The upward velocity of air is so maintained so as to slightly lift the solid particles and set them in motion. This motion can be utilized to bring about mixing as well as forward movement of the solids particles. The air is heated and the process hot air evaporates the fluid and dries the solids. Fines get agglomerated to larger granules particles thus providing large size The machine is designed with correct volume of bowl, air velocity, direction and the temperature of the clean inlet air is maintained throughout the fluidization, retarding and expansion chambers, filtration area, pitch of the perforations of the plate at the bottom of product container, the leak-proof fluidization space by proper sealing, material of the filters and process controls with electrical & pneumatically. The uniform drying is achieved by exposing the full surface of every particles of the solid mass to the incoming high velocity hot air. Option for the process parameters are controlled by using latest PLC controls with HMI touch screen thus making equipment operationally safe and eliminating the possibility of human error. The process consistency with batch records is maintained for every batch every time. The equipment can be inbuilt CIP system gives a thoroughly cleaned equipment for every batch eliminating contamination of subsequent batches. Salient Features : Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Single piece construction with Integrated retarding expansion chamber cum filter bag housing Batch type dryer with available capacity 30 kg to 500 kg. Batch size Pneumatic Sealing of Filter Bag and Product container by inflatable silicon rubber tube. Inlet Air handler with Air Filter- Micro, HEPA and Heat Exchanger Steam or Electric. Exhaust air blower with dynamic balance fan. Built in Explosion vents and isolation valve protect equipment. Automatic Temperature controls for Inlet Air and Process cycle time controls. Washable filter media, FDA approved. Auto pneumatic filter bag shacking system. Sampling pot on product container. Electric and Pneumatic controls panel. Optional Features : Additional Product container. Advance PLC controls with touch screen Double scan AHU with Dehumidifier. Steam or Electric Heater Exhaust AHU with Filter Silencer at exhaust blower. CIP - WIP system. Explosion proof motor and push button. Solid flow detection System. Differential Pressure gauge for filter. Safety Features : Product Bowl interlocking mechanism. Automatic Temperature & controls, Process cycle controls. Explosion flap ensure at retarding chamber. Safe earthling system for static current. Air pressure switch installed to ensure pressure is in limit. Overload relay Protection and Emergency stop button.

Rotary Double Cone Vacuum Dryer

Get Price Quote

we are offering rotary double cone vacuum dryer. applications rcvd is suitable for drying & mixing powder (raw materials), pharmaceutical materials, crystalline products, insecticides, pesticides, food products & also for heat sensitive products. the equipment can also be used as rotary evaporator

Freeze Dryer

Get Price Quote

In the Food and Beverage industry various products require drying to ensure required shelf life. Food products require gentle drying to preserve the products original shape, color, taste & nutrients and for these applications freeze drying process is ideally suited. Some foods freeze dry very well, but not all food is suitable for freeze drying. Small fruits and vegetables can be easily freeze dried, whereas whole fruits and large vegetables would not be suitable, although they can be freeze dried if cut into small pieces first. This also applies to meat; small chunks of meat freeze dries well, but larger fillets need to be cut into pieces. Meat and seafood also require cooking before freeze drying. For some foods freeze drying is not cost-effective. Machinfabrik designs and manufactures freeze drying machines for sale worldwide. The process typical operating sequence of the freeze drying process is as follows: Freezing of the product and freeze hold. Cooling of ice condenser Evacuation Primary drying Secondary drying

Fluid Bed Dryer

Get Price Quote

Capacity: 5 kilograms to 300 kilograms Application: To dry material by fluidisation with hot and or dehumidified air. Working Principle of Fluid Bed Dryers The atmospheric air is sucked in the dryer through 5/10 micron filter by an efficient dynamically balanced fan driven by an electric motor. The clean air then passes over the electric heaters steam or oil radiator provided with temperature controller. The hot air passes through the product and fluidisation dries the product. Dryer is provided with dehumidifier (Chilled water system) at the inlet of the dryer so as to dry the product at low temperature under fluidized condition. The blower speed is controlled by A. C. frequency drive so as to control the fluidisation avoiding choking of the filter bag. A raking system provided to avoid lump formation in the container to achieve uniform fluidisation & uniform drying. A model with complete automation and PLC, automatic bag shaking and with mimic is also offered. Promas Engineers is manufacturer, supplier and exporter of fluid bed dryers according to ISI guidelines and user’s requirements since 1990 from Mumbai to India and all over the world.

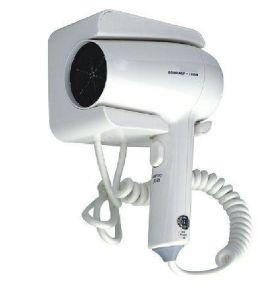

Room Groom Wall Handling Hair Dryer

Get Price Quote

Easy to comb your hair. Press the startup switch to use and release to stop double over heating protection 3 temp adjusting option 1800W high watt to dry hair faster.Wall handling hair dryer.

Floor Scrubber Dryers

Get Price Quote

Heatless Air Dryer

Get Price Quote

Compressed air coming from the Receiver containing solid, liquid & vapour contaminants enters the Dryer through the Pre-filter (where solid & liquid contaminants are removed). It then passes through Oil Removal Filter and enters into Adsorption Tower A1 through a 3-way valve (CV-1) where it gets dried and then passes out of the Dryer through the After-filter. A part of this dry air passes through Tower A2 through the Purge Control Valve, where it picks up the moisture from the adsorbent thereby regenerating it and making it ready for the adsorption cycle. The purge air exhausts out of the Dryer through Purge Exhaust Valve (CV-2) of Tower A2.

filter dryer

Get Price Quote

filter dryer, Shaded Pole Motor, Compact AC fan, Compact DC fan

desiccant air dryers

Get Price Quote

desiccant air dryers, Compressed Air Filters, process filters

Pilot Spray Dryer

Get Price Quote

Pilot Spray Dryer, Lab Spray Dryer

Paint Driers

Get Price Quote

Paint Driers, metal salts, Pvc Stabilizers

rf dryer

Get Price Quote

We Offer Rf Dryer. Features of RF Drying : •Uniform heating resulting in level drying and controlled moisture content within ±1%. •Environment friendly. Clean and safe. No effluents and No flues. •Easy to feed, operate and maintain. •No need of steam or hot air. Self contained unit. •Superb consistent quality of dryed material for feel and appearance. No chance of contamination, physical damage or colour migration. •Instant drying process. No startup and shutdown cost. Application : The RF dryer is widely used in Textile industry all over the world for drying the materials after bleaching, dyeing, mercerizing or wet processing after the initial hydro extraction process in a centrifuge to remove excess water. Any textile material in the form of fibres, Cheeses, cones, hanks, tows & tops and fabrics can be dried in a RF dryer and over the years this technology has increasingly become an accepted and preferred method for drying.

Industrial Dryers

Get Price Quote

ROBOTIC HIGH TEMPERATURE FURNACE, Scissor Lift, thyristor drive

Hair Dryer

Get Price Quote

Hair Dryer, Electric Oven Toaster