radio frequency

Get Price Quote

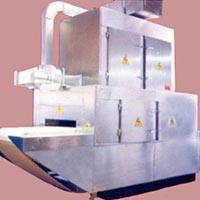

In a radio frequency heating/drying system, the RF generator creates an alternating electric field between two electrodes. The material to be heated / dried is conveyed between the electrodes, where an alternating energy field causes polar molecules in the material to continuously reorient them to face opposite electrodes much like the way bar magnets move to face opposite poles in an alternating magnetic field. Friction resulting from this molecular movement causes the material to rapidly heat throughout its entire mass. Features of RF Drying : Uniform heating resulting in level drying and controlled moisture content within ±1%. Environment friendly. Clean and safe. No effluents and No flues. Easy to feed, operate and maintain. No need of steam or hot air. Self contained unit. Superb consistent quality of dried material for feel and appearance. No chance of contamination, physical damage or colour migration. Instant drying process. No startup and shutdown cost. Application :The RF dryer is widely used in Textile industry all over the world for drying the materials after bleaching, dyeing, mercerizing or wet processing after the initial hydro extraction process in a centrifuge to remove excess water.Any textile material in the form of fibres, Cheeses, cones, hanks, tows & tops and fabrics can be dried in a RF dryer and over the years this technology has increasingly become an accepted and preferred method for drying.

Electrosurgical Snare

1,750 - 3,000 Per Piece

25 Piece (MOQ)

Having loop diameter 10to 30mm and oval design with working length of 120cm, compatible to channel of 2.0 and 2.8mm, Sterile and single use

Best Deals from Electrosurgical Units

shalya sigma 400w Electrosurgical Units

Get Price Quote

1 No (MOQ)

Electrosurgical Pencil

Get Price Quote

Electrosurgical Pencil, Hospital Equipment, Scissor, Knife Sets

Electrosurgical Equipment

Get Price Quote

Electrosurgical Equipment, Electrical Contractors

electrocautery

Get Price Quote

electrocautery, Vessel Sealer