Sprinkling System

Sprinklers are simple devices that are individually operated by the heat from a fire. When a fire starts, hot gases rise to the ceiling. If a sprinkler is present, a glass bulb or solder link gets hot and at a specific temperature (typically 68°C), it breaks, releasing a cap and allowing water to flow onto a diffuser.The sprinklers are connected to pipework, usually filled with water, which is supplied either from the water mains or from a storage tank via a pump. When a sprinkler operates, the flow of water in the pipework operates a flow switch, which, in turn operates an alarm system. The flow of water is small, usually less than 1100th of the water used by the Fire and Rescue Service.

...more

Sprinkler Head

Owing of our extremely talented team of professionals, we are engaged in offering excellent quality Cooling Tower Sprinkler Head. The offered sprinkler is manufactured using optimum quality raw material and advanced technology in adherence with industry norms. Our quality experts test this sprinkler on different parameters in order to ensure its quality. The offered sprinkler is used to achieve maximum water sprinkling at the tip of nozzles with minimum pressure drop.

...more

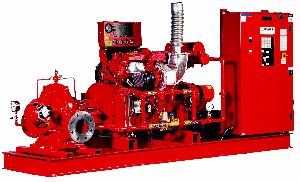

fire water pumps

These pumps are nonself-priming vertical multistage centrifugal pumps the pump consist of base and pump head. The chamber stack and the outer sleeve are secured between the pump head and the base by means of tie bolts.The base has suction and discharge connections on the same level (in-line).

...more

fire pump controller

ATS is a full service fire sprinkler and low voltage contractor. We have dedicated inspectors who are certified to inspect fire pumps, fire sprinkler, fire hydrant, and fire alarm systems. Our fire pump inspectors comply with the code requirements of the National Fire Protection Association (NFPA) 25, NFPA 72, state requirements, and city and county local ordinances. Upon completion of an inspection, ATS will provide your staff with a detailed inspection report. Our electronic inspection record systems gives us the capability to know when future inspections are due; we will call to schedule the inspection to insure your system is within guidelines.

...more

Fire Pump

The fire pump is the heart of your sprinkler system. It is the sole component responsible for supplying the water pressure needed when a sprinkler head demands it. Because municipal water pressure varies from location to location, fire pumps are customized for each specific site. Your fire pump is, by far, the most expensive component in your fire sprinkler system. These are some of the reasons why it’s important to have an experienced and knowledgeable technician maintain and service your fire pump. At Piper Fire Protection, we’ve installed, maintained, and repaired Florida’s fire pumps for the past 30 years. In fact, we have specialized employees dedicated to working on fire pumps only. The cost and importance of your fire pump demands this level of expertise. Other fire pump services we provide include: Initial water flow analysis New pump installation Grunfos jockey pump Annual flow tests Annual/Semiannual diesel service How do fire pumps work? Fire pumps are powered by an electric motor or diesel engine. If the local building code requires power independent of the local electric power grid, a pump using an electric motor may utilize what’s called a transfer switch that directs power over to an emergency generator in the event of a power failure. The fire pump starts when the pressure in the fire sprinkler system drops below a threshold. The sprinkler system pressure drops significantly when one or more fire sprinklers are activated or alternatively when other firefighting connections are opened, causing a pressure drop. Types of pumps used for fire service include: horizontal split case, vertical split case, vertical inline, vertical turbine, and end suction. A jockey pump is a small pump connected to a fire sprinkler system in parallel with the fire pump. It maintains pressure in a fire protection piping system to an artificially high level so that the operation of a single fire sprinkler will cause an appreciable pressure drop which will be easily sensed by the fire pump automatic controller, causing the fire pump to start. The jockey pump is essentially a portion of the fire pump’s control system. Fire pump installations and retrofits are governed by the National Fire Protection Association’s (NFPA)NFPA 20 Standard for the Installation of Stationary Fire Pumps for Fire Protection. FIRE PUMP MAINTENANCE An integral part of any fire sprinkler system in Tampa Bay, a fire pump provides water pressure and flow. Without a well-designed, well-maintained fire pump, even the most sophisticated sprinkler system is rendered useless, unable to draw the necessary quantities needed to contain a blaze. At A Total Solution, Inc. (ATS), we understand life safety and asset protection, with total commitment to quality for your inspection, installation, and service of both fire pumps and fire sprinkler systems. FIRE PUMP INSPECTIONS ATS is a full service fire sprinkler and low voltage contractor. We have dedicated inspectors who are certified to inspect fire pumps, fire sprinkler, fire hydrant, and fire alarm systems. Our fire pump inspectors comply with the code requirements of the National Fire Protection Association (NFPA) 25, NFPA 72, state requirements, and city and county local ordinances. Upon completion of an inspection, ATS will provide your staff with a detailed inspection report. Our electronic inspection record systems gives us the capability to know when future inspections are due; we will call to schedule the inspection to insure your system is within guidelines. Fire Pump Installations ATS installs quality fire pumps such as Fairbanks, Peerless, Aurora, Morse, and Armstrong. Our trained technicians and staff have the capability to design build, create detailed shop drawings, and generate comprehensive submittals, specifications, and complete permit packages. Our designers are a product of the University of South Florida’s highly esteemed engineering program and are NICET certified. All of our installations and repairs comply with the NFPA 20, NFPA 70, NFPA 72, and city and county requirements. Fire Pump Monitoring ATS utilizes the latest technology to 24-hour monitor your fire pump. We are not your typical “One Call Does it All” fire protection company. We have the capability to service and central station monitor 79% of all life safety and security brands. Fire Pump Repairs Without proper maintenance, a fire pump may not have sufficient water pressure to meet the hydraulic design for a particular building. Therefore, proper repairs are imperative. ATS is equipped and ready to service your fire pump, whether powered by diesel or electrical motor. We service vertical turbines, split case, vertical inline, and end line systems. Our repairs include complete trouble-shooting and replacement of malfunctioning fire pump components such as pressure switches, gauges, motor repairs, jockey pumps, and fire pump controllers. We also repack and rebuild fire pumps. All of our repairs comply with NFPA 20, county, and city requirements. Fire Pump Emergency Service 24 hours a day, 365 days a year, ATS’s fire sprinkler technicians are equipped and ready to service your fire pump. ATS’s employees are NICET, FASA/BASA, and factory certified to handle most fire pump trouble and alarm conditions.

...more

Fire Alarm Control Panels

Conventional Traditional fire alarm panels installed prior to 1998 were conventional zone panels. In a zoned system, fire alarm devices in a common area or floor of a facility are connected to the same alarm initiating circuit. Each zone requires its own circuit conductor. This arrangement allows alarm annunciation to be reported by areas of the building to identify which device is in alarm. Conventional panels are often used in small facilities where a few zones can provide sufficient alarm annunciation. Addressable With the advent of microprocessors and digital electronics, addressable fire alarm control panels and devices have become more common than conventional systems for medium and large-sized facilities. They have become more cost effective in some small applications as well. Addressable fire alarm systems use digital encoding and multiplex technology to more accurately identify alarm locations and device conditions. Each fire alarm device in a system is programmed with a unique address. The fire alarm control panel is capable of communicating with a single address or a group of addresses depending on the functions required. The communication is often multiplexed over a common cable, sometimes referred to as the signaling line circuit (SLC). This arrangement significantly reduces the amount of cabling necessary to install the system. The communication channel allows two-way communication, thus enabling the fire alarm control panel to control as well as monitor fire alarm devices. A significant component of addressable fire alarm system is the software programming necessary to make the system function correctly. The programming allows for flexible applications where you want to have specific control over the inputs and outputs. The communication technologies employed in addressable systems allow for advanced features to accommodate sensitivity changes due to age and accumulation of dust prior to maintenance. These features are not available with the standard conventional system. Fire Alarm Devices Automatic Detection Components of a fire consist of: Smoke (particulate and aerosol) Heat Light Radiation Fire detection devices are built to detect one or a combination of these components. While all components are necessary for a fire to exist, all components may not exist at a detectable threshold. Detectors will be selected that will detect the elements that may exist in a fire for the ambient conditions that are present. It also should be realized the similar non-fire components might exist in the same ambient conditions, which could cause unfavorable false alarm conditions. Devices used for fire detection include smoke detectors, thermal detectors, flame detectors, fire-gas detectors, and other devices. Smoke detectors sense visible or invisible particles of combustion generated by burning, smoldering, or the incipient stage of combustion. These devices fall into two categories -- photoelectric and ionization. Thermal detectors sense the high temperature or the temperature rise caused by a fire. Flame detectors sense the radiation produced by a fire. Fire-gas detectors sense the gases produced by a fire. Other detectors sense some phenomenon other than smoke, thermal, flame, or fire-gas to detect a fire. Smoke Detectors There are three types of smoke detectors: Ionization, photoelectric, and combination. Ionization The ionization smoke detector is widely used. Its capability to detect smoke originating from fire is best utilized for clean-burning fires that produce small particles during combustion. The ionization smoke detector consists of an alpha particle producing a radioactive source, a smoke chamber, and charged detector plates. The alpha source causes the air within the smoke chamber to become ionized and conductive As smoke particles enter the smoke chamber, the smoke particles attach themselves to the ionized air molecules and the air in the chamber becomes less conductive When the air conductivity within the chamber drops below a predetermined level, the alarm is triggered Advantages of Ionization Smoke Detectors: Detects invisible products of combustion -- It can detect fires that are in the incipient stage or detect other aerosol-type smoke products Quick acting -- Provides for earlier detection than other types of smoke detectors or thermal detectors

...more

Annunciation System

Teknika 8 10 fault annunciators are digital units with front end lit by LED's. Applications are in monitoring fault conditions in any process, equipments etc. A potential free fault condition triggers a buzzer, trip contact and a contact for hooter if external hooter is desired. Also the corresponding window flashes, two changeover contacts trip to signal trip indication and an internal buzzer beeps to signal fault condition. When the acknowledge pushbutton is pressed the flashing becomes steady, the buzzer stops and the hooter contact is released. Test checks all the windows.

...moreBe first to Rate

Rate ThisOpening Hours