Pressure Vessels

48,859 Per Set

Reaction Vessel

Get Price Quote

Reaction Vessels eith / without Agitator Size - As per requirement. Type - Cylindrical with flat, conical, dish type top / bottom Agitator - High efficiency leading to reduction in power consumption Gearbox, motor, independent mounting structure & suitable sealing arrangement as per requirements. DOLPHIN akso provided cooling or heating coil made out of different materials as per the customer's requirement.

Best Deals from Spiral PP Chemical Reaction Vessel

High Pressure Vessel

3,000,000 Per Pack

Plastic Crates

299 - 999 Per piece

10 piece (MOQ)

Swift offers Premium grade superior quality plastic crates which are made up from virgin grade polyethylene plastics. The range of plastic crates is designed to suit Fruit & vegetable crates, Milk crates for dairy industries, banana crates, and Industrial Crates with Lid, These crates can be manufactured in different colors and sizes as per customer requirements. Plastic crates are available in different variants. Available in different sizes.

Galvanized Iron Nitrogen Storage Pressure Vessel

Get Price Quote

1 Piece (MOQ)

Stainless Steel Jacketed Vessel

300,000 Per Piece

1 Piece (MOQ)

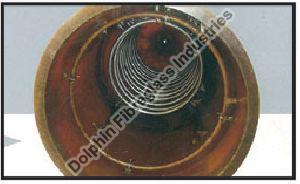

Limpet Coils

Get Price Quote

We are offering limpet coils.

Pressure Vessels

Get Price Quote

The pressure vessels, which we deliver, are manufactured using supreme-grade steel which ensures the high mechanical strength of the vessels. The double layer walls of the vessel prevent the rupture due to excessive pressure. We make available pressure vessels in bulk quantities, at market leading prices.

Homogeniser

Get Price Quote

Heavy fuel oil has been homogenised successfully for many years. This process considerably improves the fuel quality and results in a better combustion. The homogeniser breaks up the long asphaltene chains in the fuel and enables these to be burnt accordingly. Several ship owners have reported 1% fuel savings and it is also possible to use the LEMAG FQI to reduce sludge by approx. 50%.

Frp Reaction Vessels

Get Price Quote

We are Maharashtra, India based top-notch Manufacturer & Supplier of FRP Reaction Vessels in the domestic market. The offered FRP Reaction Vessels are cylindrical vertical agitator assembly vessel along with complete stirring arrangements in PVC/FRP, with stirrer, mechanical seal, motor and gearbox. They can also be designed and fabricated having conical bottom. Buyers can get them in tailored specifications as well. Various materials like FRP, PVC, CPVC, PP, PVDF, ECTFE, etc. can be used suiting to the reacting chemicals and temperature conditions.

electrical reactors

Get Price Quote

We at TRANSPOWER have an extensive record as a trusted manufacturer of wide range of Transformers (which includes Oil filled, VPI and Cast Resin), reactors/chokes, CTs, PTs & coils to cater different industries as per the applications & specifications of customers. As we are committed to customer satisfaction by providing wide range of power solutions, we had great interaction with different field customers with their challenging requirements. Our organisation core competency got evolved over the years to benchmark ourselves against global leaders by utilizing strategic combination of our last 30 years’ experience, design capabilities, innovative ideas. Further this helped us to have better access to most advanced magnetic & insulating materials to provide our customers quality products with optimum cost. Presently we design, develop, produce and deliver wide range of high quality Magnetics as per international standards. Transpower India Electronics is having well established infrastructure to produce wide range of Reactors, Inductors for different applications as per IEC, and IS standards. Transpower India Electronics is having well established infrastructure to produce wide range of Reactors, Inductors for different applications as per IEC, and IS standards. Dry type Reactor is a necessity component in the power quality management, supressing unwanted harmonics and signal shaping hence the loss reduction which could be translated in an overall cost reduction, mainly in industrial applications. Vacuum Pressure Impregnated Reactors are generally used for low voltage and to some extent medium voltage applications. In certain applications particularly in medium voltage cast resin reactors are used. TIE AC reactors intended for series connection in a system for limiting current or for load sharing purposes are available in wide range of current rating and inductance value. DC reactors to filter out all harmonics present in DC power systems of high or low system voltages are available. Supressing harmonics of any frequency range with less core loss is an essence in our DC reactor designs. TIE manufacturing scope for reactors and Inductors: As per IS 5553 part 1 to 5, Single Phase or 3 Phase VPI or Resin cast AC Reactors which includes: Output Reactors for Harmonic Suppression Line Reactors Shunt Reactors Sine filter reactors DC Reactors High Frequency Reactors Air Core Reactors Range: Up to 22KV Up to 3000A with or without enclosures (IP series) Salient Features: Tailor made as per customer requirement for wide range of applications. Optimum design Rugged construction Low noise Long life

Hdpe Spiral Reaction Vessel

Get Price Quote

The finest hdpe is sourced from the renowned vendors in the industry, to make sure that our hdpe spiral reaction vessels impart longer life along with lesser maintenance. The company is known as the prime hdpe spiral reaction vessels manufacturer, exporter, and supplier in india. Our hdpe spiral reaction vessels are offered at affordable prices. attributes sturdy low maintenance non-corrosivetemperature resistant we offer ms structured that holds the vessel, agitator, & gearbox assembly

FRP Mixing Vessel

25,000 Per unit

Multipurpose Reaction Assembly

Get Price Quote

Capacity: 10 litres to 20,000 litres Application: To conduct various types of reactions multipurpose reaction assembly like esterification, etherification, nitration, alkalisation, hydrolysis, hydration, dehydration, sulphonation, reduction, oxidation under alkaline conditions, condensation, polymerisation etc. We are certified manufacturer, exporter and supplier of multipurpose reaction assemblies as per the client’s requirements and need since 1990. Working Principle Multipurpose Reaction Assembly The unique design allows the following unit operations to be conducted efficiently. Solvent recovery, distillation, liquid-liquid extraction, phase separation, dissolution, de-emulsification, heating, cooling, blending, degassing, flash distillation etc. Efficient condenser allows complete condensation of vapours and minimises losses. The subcooler, receiver and vapour trap facilitates recovery of all the material by distillation under reduced pressure. The limpet and the internal coil is provided for cooling as well as heating. The system is designed to facilitate conducting reactions under auto pressure / reduced pressure / under inert atmosphere under subzero temperature as well as temperatures up to 300 C.

Surge Control Vessel

Get Price Quote

Plastic Crates

Get Price Quote

We are main suppliers of this product.

Stainless Steel Pressure Vessel

10,000 Per Units

process vessels

Get Price Quote

We follow the highest standard factory acceptance testing, including material identification, Ra testing, Riboflavin test, Spray ball testing and Hydro testing. We include full documentation packages with weld inspection reports and Ra mapping.

Multipurpose Reaction Assembly

Get Price Quote

Application: To conduct various types of reactions multipurpose reaction assembly like esterification, etherification, nitration, alkalisation, hydrolysis, hydration, dehydration, sulphonation, reduction, oxidation under alkaline conditions, condensation, polymerisation etc. We are certified manufacturer, exporter and supplier of multipurpose reaction assemblies as per the client’s requirements and need since 1990. Working Principle Multipurpose Reaction Assembly The unique design allows the following unit operations to be conducted efficiently. Solvent recovery, distillation, liquid-liquid extraction, phase separation, dissolution, de-emulsification, heating, cooling, blending, degassing, flash distillation etc. Efficient condenser allows complete condensation of vapours and minimises losses. The subcooler, receiver and vapour trap facilitates recovery of all the material by distillation under reduced pressure. The limpet and the internal coil is provided for cooling as well as heating. The system is designed to facilitate conducting reactions under auto pressure / reduced pressure / under inert atmosphere under subzero temperature as well as temperatures up to 300 C.

Pressure Vessels And Reactor Vessels

Get Price Quote

We supply pressure vessels of varying capacity as per International codes like ASME, DIN and BS Standards for leading industries. We have manufactured pressure vessels with wall thickness up to 80 mm. Different categories of vessels manufactured by us are Jacketed type vessel Vessel with limpet coils Reactor vessels with agitators Low temperature vessels We provide different types of dish ends for thepressure vessels as per requirements viz. Ellipsoidal Torispherical & Hemispherical dished ends.

Pressure Vessel

Get Price Quote

We manufacturer pressure vessels for Air and Gas systems.

Multipurpose Reaction Assembly

Get Price Quote

Capacity: 10 litres to 20,000 litres Application: To conduct various types of reactions multipurpose reaction assembly like esterification, etherification, nitration, alkalisation, hydrolysis, hydration, dehydration, sulphonation, reduction, oxidation under alkaline conditions, condensation, polymerisation etc. We are certified manufacturer, exporter and supplier of multipurpose reaction assemblies as per the client’s requirements and need since 1990. Working Principle Multipurpose Reaction Assembly The unique design allows the following unit operations to be conducted efficiently. Solvent recovery, distillation, liquid-liquid extraction, phase separation, dissolution, de-emulsification, heating, cooling, blending, degassing, flash distillation etc. Efficient condenser allows complete condensation of vapours and minimises losses. The subcooler, receiver and vapour trap facilitates recovery of all the material by distillation under reduced pressure. The limpet and the internal coil is provided for cooling as well as heating. The system is designed to facilitate conducting reactions under auto pressure / reduced pressure / under inert atmosphere under subzero temperature as well as temperatures up to 300 C.

PHARMA VESSEL INSULATION

Get Price Quote

The insulation of pharmaceutical vessels is done to preserve the temperature inside the vessels. These vessels are of irregular shape. For void free insulation and to avoid sweating over the surfaces proper insulation is required. Insulation properties of polyurethane foam are much better than other insulating material hence it is preferred over other insulating materials. Cladding is done over the vessels using various surfaces such as • GI Pre coated • Aluminium • SS Thickness of insulation varies as per the ambient temperature and the internal temperature of the vessel to be maintained. The density of Polyurethane foam insulation is maintained around 40kg/m3. Higher densities are also achieved as per the requirement of the customer. PIR can also be used as an insulating material. Dual insulation can also be done as per requirement of customer. Advantages with in-situ foaming system:: • The risk for voids in the insulation is eliminated by the spray method • No joints in the foam • Homogeneous insulation • Increased insulation efficiency • Increased tightness • None-corrosive and watertight cladding • Complete bonding to all surfaces • No penetration or space for accumulation of moisture • Excellent corrosion protection • Good fire fighting properties • Easy to Insulate Uneven Surfaces, Corners, Supports and Odd Geometrical Shapes

Pharmaceutical Mixing Vessels

Get Price Quote

Reaction vessel are one of the most important equipments of any Chemicals, Drugs and Pharmacy industries. Stirrer mixing vessel with magnetic drive or mechanical seal. IUS manufactures high quality durable and safety proven tanks and pressure reaction vessels as per CGMP standards. Our experience ranges from simple storage vessels to complicated Chemical reactor systems with online auto mode recording & cleaning system. We stand guarantee for the process engineering, Operational conditions and sequences. We have unique combination of in-depth knowledge of engineering design with flair for documentation. The technical implementation takes place by the external and internal installation of components such as mixing Units, heating or cooling. In combination with biological and chemical operational sequence. Pressure vessel systems have contributed to the high Standard of living existing today in the technically advanced countries. Their complexities are marvels of engineering capability as they continuously produce useful products. There are various type of reaction vessel viz. Jacketed, Limpet coil in body flange or Welded types, Vertical or Horizontal reactors.

Chemical Reactors

Get Price Quote

Chemical Reactors, blenders, pharmaceutical products, Mixers

Mixing Vessel

Get Price Quote

Mixing Vessel, blending vessel, Masala Mixer, Tray Dryer, Tableting Machine

Pressure Vessels

Get Price Quote

Pressure Vessels, customized gear box, Machine Components, machine spares

Liquid Manufacturing Vessel

Get Price Quote

Liquid Manufacturing Vessel, Nail Polish, research development

Pressure Vessels

Get Price Quote

Pressure Vessels, vaporizers, Marine Chilling Compressor

pharmaceutical equipment like glass lined reactor

Get Price Quote

pharmaceutical equipment like glass lined reactor, blenders, Storage Tanks