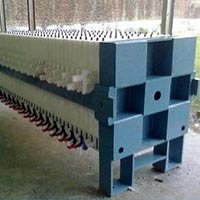

Fully Automatic Filter Press

Get Price Quote

We are main supplier of this product.

CGR(Zero Leak) Type Filter Press

Get Price Quote

These are advance version of Recessed Chamber Closed configuration plates, where Filter Cloth is caulked in the caulking groove around the recess plate. Major benefits of this design are Zero leak Recess Type Filter Plate because ‘O’ Ring seats around the sealing edge and filtrate hole secure tight seal when the plate pack is closed. Cloth caulking groove provide easy installation and least maintenance of the filter cloth. CGR plates are recommended and necessary for leak proof conditions like toxic substance, acidic solutions etc. ‘O’ Ring are available in the different elastomers like EPDM, Neoprene, viton etc. These plates are available with center, top, bottom and corner feeding with adaptable diameter and designed at 8 and 16 bar operating pressure.

Best Deals from Cast Iron Filter Press

Semi Automatic Filter Press

Get Price Quote

In our range of Semi-automatic Filter Press the maximum pressure will be 25MPA in hydraulic devices by using electro connecting pressure gauges. 1.0 MPA is the maximum filtration pressure can be applied for the optimum condition for pressure filtration or cake formation. The control panel is simple and user-friendly with easy operation.

Membrane Filter Plates

Get Price Quote

the membrane filter plates are the technological development of the recessed plates. These elements come with variable chamber depth which is adjusted depending upon the filterability and quality of slurries to be treated. Mixed pack membranes are the most common & cost effective configuration where the membrane and recessed plates are set alternatively so every second plate is provided with flexible and replaceable filter face of rubber on both the side. This configuration allows variable chamber depth through membrane squeezing. These plates are mainly used to increase the cake dryness (reduce moisture content), shorten filtration, effective washing and discharge time and they are achieve by inflating the flexible membrane diaphragm filter face, contrary to conventional plates. For inflation of membrane generally water or air pressure is used by pumping in the squeezing chamber. the replaceable membrane are either from rubber or ep family which has great advantage of elasticity gives extreme deflection of membrane so the final cake receive the consistent high dryness. due to squeezing process the membrane plates offers following advantages.- reduction in moisture content in the final filter cake- reduction in filtration, washing as well discharge time.- reduction of washing liquid consumption due to more homogeneous cake structure.- increased uniformity in dewatering of the filter cake.- improvement in cake release from the filter press. - saving in filtration process cost and time. membrane plates are available with center, top center and corner feed designs for up to 16 bar operating pressure.

Plates & Frames

Get Price Quote

Products Filter Plates Products Filter Plates Filter Press Automatic Filter Press Working Demo Application Inquiry Contact Us Home Chamber Plates & CRG Filter Element Chamber plates in standard design are fabricated of pressure-resistant andcorrosionproof polymer. Other materials such as cast iron, ductile iron, aluminum,stainless steel available on request. Filtrate discharge is available either in open design through spigots into a filtrate trough or in closed design through corner ports into discharge pipes. Plates & Frames Plates and Frames are made of light, hygienic, chemical resistance polypropylene. They are easy to handle and practically maintenance free. Plates and frames are uniquely suited for basic filtration processes. They have been proven reliable and efficient in chemical processes, the beverage industries, and biochemical, pharmaceutical, and blood and plasma applications. The sizes are from 610mm to 1200mm.

Semi Automatic Filter Press

Get Price Quote

each fitted with a durable permeable cloth. The recessed plates are pushed together in normal operation. The pressure required for dewatering is provided by the feed pump. During the filtration cycle the sludge is initially pumped into the chambers at a high rate. This rate is reduced as the chambers are filled and the pressure builds. The cloths retain the solids, allowing water to pass through as filtrate. Once the pressure in the press reaches a set point and the filtrate is reduced to a trickle the dewatering cycle is complete. The next stage of the process is to empty the press by opening the plate chambers and allowing the dewatered cake biscuits to drop out. This entire operation can be a manual, semi automated or fully automated process. Once the press is empty the plates are returned to the closed position, ready for further batches. The manual filter press unit is fitted with a hand pump, and is ideal for small sludge volumes. The semi-automatic filter press range, with a hydraulic pump for plate pack closing. The fully automatic machine includes automatic plate shifting, plate vibration and drip trays. A number of options are available to assist ease of operation for all models, including the Air-Track plate shifter, membrane plates for increased filtration pressures.

Filter Plate

Get Price Quote

Filter plate Recessed chamber plate,Gasket chamber plate,Non-gasket chamber plate, Membrane squeeze plate,Plates and Frames up to 6kgcm2 operations,5 kgcm2 to 15kgcm2 operations.

Membrane Filter Plates

Get Price Quote

The Membrane filter plates are the technological development of the recessed plates. These elements come with variable chamber depth which is adjusted depending upon the filterability and quality of slurries to be treated. Mixed pack membranes are the most common & cost effective configuration where the membrane and recessed plates are set alternatively so every second plate is provided with flexible and replaceable filter face of rubber on both the side. This configuration allows variable chamber depth through membrane squeezing. These plates are mainly used to increase the cake dryness (reduce moisture content), shorten filtration, effective washing and discharge time and they are achieve by inflating the flexible membrane diaphragm filter face, contrary to conventional plates. For inflation of membrane generally water or air pressure is used by pumping in the squeezing chamber. The replaceable membrane are either from Rubber or EP family which has great advantage of elasticity gives extreme deflection of membrane so the final cake receive the consistent high dryness. Due to Squeezing process the Membrane Plates offers following advantages.– Reduction in Moisture content in the final filter cake– Reduction in Filtration, Washing as well discharge time.– Reduction of washing liquid consumption due to more homogeneous cake structure.– Increased Uniformity in dewatering of the filter cake.– Improvement in cake release from the filter press.– Saving in filtration process cost and time. Membrane plates are available with center, top center and corner feed designs for up to 16 bar operating pressure.

Semi Automatic Filter Press

Get Price Quote

We manufacture Semi Automatic Filter Press with electro mechanical plate shifting device for individual Plate shifting with a Pick and Plate type Reciprocating shuttle. For shifting with total speed control, Hydraulic or electric motor is used. We offer the highly efficient Semi Automatic Filter Presses.

Membrane Filter Press

Get Price Quote

Membrane Filter Press, Automatic Filter Press, screw type filter press

Filter Press

Get Price Quote

Filter Press

Filter Press Machine

Get Price Quote

Filter Press Machine, Sand Mill Disc, Polypropylene Cock

Cast Iron Filter Press

Get Price Quote

Cast Iron Filter Press, Manual Filter Press

Hydrocyclone Filter

Get Price Quote

Sand Filters, Screen Filters, L Type Screen Filter, Metal Body Disc Filter