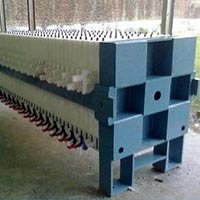

Membrane Filter Press

Get Price Quote

The working room of the membrane filter press consists of chambers, limited by two adjacent plates with recesses in the central part. Unlike the chamber plates, the drainage draining the filtrate is located on movable membranes serving for pressing and “wringing” of the filtrated cake. Water or air under pressure is used to compress the membranes. Once the filter press is filled with the suspension, this medium is fed to the room under the membranes and its subsequent lifting compresses the cake and pushes out the residual liquid. The liquid passes through the cloth and is discharged out of the filter press. The thickness of the filtration chamber is usually 30 – 50 mm before compressing, by compressing the membrane it is reduced most often by 20 – 40%.The suspension is fed via a central or corner inlet passing through the whole set of plates. The filtrate is drained by drainage on the membrane surface (under clothes) and then by channels drilled inside the plates out of the filter press. Filtrating (filling) pressure before the start of the membrane compression is usually 8 bars, it rises up to 15 bars during compressing (structurally, we manufacture filter presses to a maximum pressure of 30 bars).The filter presses are equipped with a security system, which will not enable opening of the filter presses if the system of membrane compression was not previously decompressed. This prevents from damaging to the membranes by accidental opening of the filter press. The filtration plates including membranes are standard made of polypropylene, another material can be chosen.

Membrane Filter Press

Get Price Quote

Here the process of Membrane Filter Plate is applicable. After the pressure is achieved on the preset the sludge stops entering into the chamber and the membranes are inflated. The chamber below has a drainage through which Air or water is used to generate pressure and is pumped inside the squeeze cavity to inflate the face of the plate against the filter cake. The cake is dewatered and then removed from the chamber.Less filtration time. Uniform filter cake for continuous output. Dry cake matter content as squeezing procedure is involved. Low Investment cost. High Acceptability to all Product compositions. Low energy consumption.

Best Deals from Membrane Filter Press

Membrane Filter Press

Get Price Quote

Membrane Filter Press, Automatic Filter Press, screw type filter press

Membrane Filter Press

Get Price Quote

Membrane Filter Press, Ready Made Garments, polypropylene filter plates