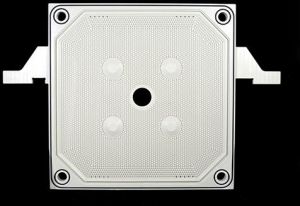

recessed filter plates

The recessed filter plates are the successor of Filter plate and frames. There are 2 basic configuration of Recessed filter plates: Open Discharge & Close Discharge. In both the configuration the chamber depth is definitive. In the Open Configuration plates, filtrate discharges to be either a adaptable Bib or spigot on one side or both the side of the plates. In this type of design the discharged filtrate can be visible from each plate and can identify torn filter cloth or other retention problem.The Closed configuration plates, discharges filtrate either from 0 to 4 corners or adapted external outlets. Holes in the corner shaped into tunnel or pipe in the series of plates and discharged filtrate are collected at the feed end of the filter press. For external examination or for non hazardous filtrate, spigots can be used. Our recessed filter plates are correctly design, necessary for economic operation and short process time. They are single piece moulding which prevents the problem of cracking, leakage and corrosion. The polypropylene light weight and trouble free construction provide easy handling of the plates. The Piped-Capsules as well slotted grooved drainage design in the plate provides excellent support to the filter cloth and allows filtrate to discharge along the base of the plate with the least resistance. Piped drainage designs enhance filtration and washing efficiency. These plates are available with centre, top, bottom and corner feed designs and operated up to 8 or 16 bar pressure.

...more

Membrane Filter Plates

The Membrane filter plates are the technological development of the recessed plates. These elements come with variable chamber depth which is adjusted depending upon the filterability and quality of slurries to be treated. Mixed pack membranes are the most common & cost effective configuration where the membrane and recessed plates are set alternatively so every second plate is provided with flexible and replaceable filter face of rubber on both the side. This configuration allows variable chamber depth through membrane squeezing. These plates are mainly used to increase the cake dryness (reduce moisture content), shorten filtration, effective washing and discharge time and they are achieve by inflating the flexible membrane diaphragm filter face, contrary to conventional plates. For inflation of membrane generally water or air pressure is used by pumping in the squeezing chamber. The replaceable membrane are either from Rubber or EP family which has great advantage of elasticity gives extreme deflection of membrane so the final cake receive the consistent high dryness. Due to Squeezing process the Membrane Plates offers following advantages.– Reduction in Moisture content in the final filter cake– Reduction in Filtration, Washing as well discharge time.– Reduction of washing liquid consumption due to more homogeneous cake structure.– Increased Uniformity in dewatering of the filter cake.– Improvement in cake release from the filter press.– Saving in filtration process cost and time. Membrane plates are available with center, top center and corner feed designs for up to 16 bar operating pressure.

...more

Filter Plate & Frame

The original concept for filter press were the Filter plate & frame, are still used in many industries. In these design the chamber is formed by a pipped or slotted grooved flat plate on each side of the frame and Cake formation takes place in the frame. Filter plate & frame are still valid solutions in application where low solid feeds are present as well filtrate quality and cake washing/ extraction are important.These plates usually used in applications where filtration area is more important than volume. Filter plate & frame are available in polypropelene – HP/CP material which application is suitable upto 800C. Our standard plate & frame configuration covers wider range of applications in the variety of industries and customized designs also met the specific process applications.

...more

Customized Plate

As per the specific requirement of the customer , special size and customized design made available on request.

...more

Chamber Filter Plates

Available with us is a wide range of Chamber Filter Plates that are fabricated using the superior quality raw material. These are in accordance with the specifications of our clients and are high on performance and precision.

...more

CGR Filter Element Plates

We are one the foremost organizations involved in manufacturing and supplying of CGR Filter Element Plates & Frames. These product are made from high quality raw material. They are known for their durability and sturdiness. We deliver CGR Filter Element Plates & Frames in different shapes and sizes.

...more

Caulked & Gasketted Plates

These are advance version of Recessed Chamber Closed configuration plates, where Filter cloth is caulked in the caulking groove around the recess of plate. Major benefits of this design are Zero leakage because ‘O’ Ring seats around the sealing edge and filtrate hole secure tight seal when the plate pack is closed. Cloth caulking groove provide easy installation and least maintenance of the filter cloth. CGR plates are recommended and necessary for leak proof conditions like toxic substance, acidic solutions etc. ‘O’ Ring are available in the different elastomers like EPDM , Neoprene , viton etc. These plates are available with centre, top, bottom and corner feeding with adaptable diameter and designed at 8 and 16 bar operating pressure.

...moreBe first to Rate

Rate ThisOpening Hours