Waste Water Treatment Plant Spare Parts

Waste Water Treatment Plant Spare Parts that we offer includes Filter Press, Tube Settler, Flow Meters, FRP Vessels and Multi Port Valves, Aeration Systems, S.S. Bar Screens, MBBR Media, Feed Pumps, Chlorine and Chemical Dosing Pumps, Agitators and Mixers and many more. We are enlisted among the top Manufacturers and Suppliers of Waste Water Treatment Plant Spare Parts from Noida, Uttar Pradesh. The entire range of our Waste Water Treatment Plant Spare Parts is manufactured in compliance with the set industry standards.

Brand Name : Biotech

...more

sewage waste water treatment plant

200,000 - 800,000 Per piece

We provide a very energy efficient system for sewage and industrial effluent. An aeration system which is 100% silent and needing zero maintenance A 50 KLDay system would cost around Rs. 4.50 lacs.

Type : Sewage Water Treatment Plant

Certification : ISO 9001:2008

Weight : 100-1000kg

Color : Brown

Voltage : 220V

Automatic Grade : Semi Automatic

Power : 10-15kw

Driven Type : Electric

Warranty : 1year

Brand Name : Biotech1

...more

Septic Tank Aeration Unit

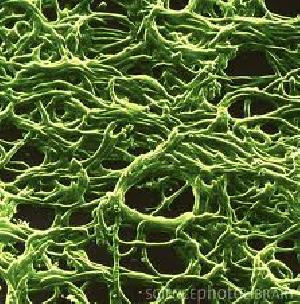

Septic Tank Aeration Unit is a Compact aeration system used to treat small and variable quantities of sewage or industrial waste water. The system is designed on the basis of up flow, attached growth system of treatment for waste water. It consists of a small aerating pump consuming 40 Watts to 200 Watts of power, a suitable air diffuser, MBBR Media for attached growth with proprietary blend of microbes. The bottom of Septic Tank Aeration Unit includes a Bio Filter. The very specific design of the container ensures that all of the wastewater moves over the MBBR Media, rather, as opposed to a chance factor in the regular system. The aerating pump of our Septic Tank Aeration Unit does not require maintenance. Various models of Septic Tank Aeration Unit are available to treat sewage wastewater from 500 to 6,000 liters per day; Delivering 10 to 75 liters per minute of air and 20 to 60 sq. meters of surface area, in the MBBR Media, for bacterial growth. Multiple Units of Bugsy can cater to larger volumes. Bugsy is available in each model. Technical Details of Operations (Model – B300/75) : For a 5,000 Liters per Day of Effluent, 75 liters / minute of air is released into the effluent. With a transfer efficiency of about 12.5% it has the capacity to degrade 3 Kgs of B.O.D. per day, which translates to 1.8 Kg of B.O.D.5 per day, which is also treatable by the 60 sq. meters of MBBR Media. Air Pump consumes 200 watts of power. Can reduce B.O.D. by 85 to 95%

Material : High Quality Raw Material

Condition : Good

...more

MSEP Sewage Waste Water Treatment Plant

MSEP Sewage Waste Water Treatment Plant is manufactured using thick MS sheets and coated with Epoxy paint. The coating can also be done with Epoxy Resins or even Fiberglass Reinforced Plastics (FRP). The whole system is skid mounted. It is a compact water treatment plant based on MBBR process. We are counted among the top Manufacturers and Suppliers of MSEP Sewage Waste Water Treatment Plant from Noida, Uttar Pradesh. We make available different models of this plant for 5 KL/Day to 30 KL/Day. Functionality : The Plant is fed from an underground collection tank (naturally, as sewer lines would be coming underground) by pumping the sewage wastewater into the system. MBBR / FAB Media of adequate quantity is being put in the aeration chamber. The aeration is done by either air diffusers, fed by diaphragm air pumps or by Italian Jet Aerators which are based on the Venturi system. Biodegraded waste water is taken into a settling tank by gravity and the overflow from there (after clarification) is pumped for tertiary treatment, Dual Media Filter or Multi Grade Filter and Activated Carbon Filter. On the way it is dosed with Chlorine.

Condition : Good

Brand Name : Biotech

...more

MBBR Sewage Waste Water Treatment Plant

MBBR Sewage Waste Water Treatment Plant is based on MBBR system and Bio-augmentation. We are a well-known Manufacturer and Supplier of MBBR Sewage Waste Water Treatment Plant from Noida, Uttar Pradesh. The unique feature of our MBBR Sewage Waste Water Treatment Plant is to use Effective Microbes in the MBBR system which ensures better growth of microorganisms, which are far more effective and potent as compared to those, obtained from cow dung or activated sludge. MBBR Sewage Waste Water Treatment Plant can withstand shock loads and variations in temperatures and pH values.Advantages : We normally recommend installation of Stormix Submersible Jet Aerator(s). They are aerators specifically designed for Wastewater treatment. It imparts a very high Oxygen transfer rate for every Horse Power consumed and which is 40 – 42 KGs per Day. This is a highly energy and cost efficient system, made in Italy and is of Stainless Steel with a Sacrificial Anode to prevent damage to the Submerged System. The entire system is floating and can be moved as required. Most importantly does not require any regular maintenance, such as lubrication and is considerably silent. Normal Intrinsic Bacteria from within the sludge and sewage is not adapted to shock loads, pH and temperature variations. We provide a special Bacterial culture Biorganic to tackle all sorts of Wastewater. This reduces sludge, consumption of power, due to lesser aeration needs and a more comprehensive treatment. Our culture contains 56 strains of Bacteria and Fungi. Every milli liter contains a million Colony Forming Units. The use of Plastic (MBBR) Media (Fluidized) ensures active growth of Bacteria and higher Biomass, resulting in lower retention period to treat the Sewage. With proper growth there is no need for sludge recycling as is normal. This media is also commonly known as MBBR or FAB or Bio Pac Media and has a surface area of 900 sq. meters per cubic meter. The installation of an Ultra Violet Dosing is the ultimate in Tertiary Treatment. It removes all pathogens and most odor from the treated water so that it can be put to several reuses, such as gardening, washing of paths and roads and even ground water recharging to replenish the water table. Sludgeless Treatment Systems are being designed by us for lesser flows, which allows the solids to settle at the bottom of a tank (after Biodegradation). In the presence of Microbes and Dissolved Oxygen in Water, the sludge is further degraded into Carbon Dioxide and Water, in time, leaving behind dead Bio Mass.

Condition : Good

Brand Name : Biotech

...more

effective microbes

88 Per Litre

Effective Microbes with a Billion CFU per liter, For all grades of effluent, Industrial or Sewage. This ensures complete treatment of the effluent, overcoming power cuts, shock loads. These also ensure that the living microbes are always there in the system. Avoids use of any nutrients.

...more

Covid 19 Air Sterilizer

Pulire air sterilizers a state of the art system with one of the most strong oxidising / reducing agents - a hydroxyl radical (neutral -OH). The hydroxyl radical is known as the detergent of the troposphere. it is not just an air purifier but a sterilizer, it is not just a photosynthesis (action of ultra violet rays - uv) system. it is a photocatalytic system producing the hydroxyl radical : -OH ion, neutral ion, even breaks the virus SARS Cov-2 causing Covid19. The hydroxyl radical is capable of breaking the RNA /DNA of various viruses, like SARS Cov 2 which causes the Covid19 flu. it can eradicate, spores, fungus, bacteria. The Hydroxyl Radical is particularly unstable and will react rapidly and non-specifically with most biological molecules. (this species is produced from the action in air, of ultra violet rays on nano particles of titanium dioxide). These reactions lead to lipid peroxidation and oxidizing DNA or RNA of proteins (SARS-Cov-2) to mediate cell damage. Pulire produces the Hydroxyl Radical that acts on the RNA / DNA of proteins. The Hydroxyl Radical also reduces all noxious and toxic gases, H2S, SO2, NOx, etc. System are available for anything between 200 sq. Ft. To 550 sq. Ft.

Frequency : 50 Hz +/- 2%

Weight : 2.70 kg

...more

air sterilizers

20,000 - 35,000 Per Piece

1 Piece(s) (MOQ)

pulire air sterilizers a state of the art system with one of the most strong oxidising / reducing agents - a hydroxyl radical (neutral -oh). The hydroxyl radical is known as the detergent of the troposphere. it is not just an air purifier but an sterilizer, it is not just a photosynthesis (action of ultra violet rays - uv) system. it is a photocatalytic system producing the hydroxyl radical : -oh ion, neutral ion, even breaks the virus causing covid19. the hydroxyl radical is capable of breaking the rna of various viruses, like sars cov 2 which causes the covid19 flu. it can eradicate, spores, fungus, bacteria. the hydroxyl radical is particularly unstable and will react rapidly and non-specifically with most biological molecules. (this species is produced from the action in air, of ultra violet rays on nano particles of titanium dioxide). these reactions lead to lipid peroxidation and oxidizing dna or rna of proteins (sars-cov-2) to mediate cell damage. pulire produces the hydroxyl radical that acts on the rna of proteins. the hydroxyl radical also reduces all noxious and toxic gases, h2s, so2, nox, etc. system are available for anything between 200 sq. Ft. To 550 sq. Ft. visit www.pulire.info for more detailed information.

Type : Uv Air Sterilizer, Air Sterilizer

Certification : CE Certified, ISO 9001:2008, GMP

Voltage : 220V

Frequency : 50Hz

Power : 0-200w

Warranty : 2yrs

Automation Grade : Fully Automatic

Brand Name : Pulire

Color : Fawn

...more

Air Purifier Sterlizer

30,000 Per Piece

Here is a product that is quite advanced from what you normally hear about. This produces an action of Ultra Violet (UV-C) on Titanium Dioxide, which generates the neutral Hydroxyl ion, one of the strongest sterlizing agent known to man. All sizes of the system are available for domestic use to hospitals and clinics, board rooms of corporates, shops and nurseries. A very effective advertising tool.

Brand Name : Radic8

Country of Origin : Korea

...more

Septic Tank Treatment

Septic Tank Treatment is done by Compact Aeration Units (Services). Septic Tank Treatment is a cost effective solution for daily sewage flow of up to 60000 liters (or domestic sewage generated by about 600 persons). We have installed treatment facility in the Septic Tank at the farmhouse of the very well known Mr. Ajay Kalsi on NH8.Biorganic Puts Nature To Work : After installing the Compact Aeration Unit – Bugsy into any single or either of a two chamber septic tank system, the Biorganic Blend of powerful Biological agents immediately begins processing waste (including nitrates) within the tank and continues to work in the soak pit. Conventional septic systems have one basic flaw : they try to fool Mother Nature. Over billions of years it evolved aerobic (air – breathing) bacteria as the most effective organism for removing bio waste from the environment. Septic tank sends only partly digested wastes into the soil. Sadly slime generating fecal bacteria dominates the process, clogging the soil of the soak pit. The system is of two components, the Bugsy bacterial generator cum multiplier and the Biorganic blend of 56 specialized, strengthened and adapted microbes, suited for most effluents – industrial or domestic . The Bugsy generator consists of a diffuser and air pumping system, consuming about 200 watts of energy (suitable for 5000 to 6000 liters per day of sewage) and where the microbes grow (over a plastic media, known as MBBR Media), survive, oxidize and move with the discharged wastewater. Problems in Septic Tanks : Septic Odours of Methane and Hydrogen Sulphide Ingests Nitrates into soils Slime producing; results in clogging Bio Mat Needs frequent cleaning of Septic Tank and Soak Pit or Leach Field Treated wastewater contains large quantities of organic matter. What Bugsy does to solve these problems? Restores problematic systems Shows Improvement Immediately Eliminates Foul Smell Protects new systems Helps in water recharging Protects environmentally friendly locations Can be installed in existing tanks How does the Bugsy Work : The Bugsy is the most efficient aerator of the system, sending streams of micronised air, with a high Oxygen Transfer Efficiency, into the wastewater. The high exposure to Oxygen simply kills the anaerobes within the System. The Bugsy also inoculates the Septic System with the Biorganic blend of Bacterial Culture. This bacterial culture builds up a huge population (known as Bio Mass) within the Generator, while growing on the MBBR media installed in the system as well as in the Septic Tank, causing the wastewater solids to oxidize and degenerate into Carbon Dioxide and Water. The Biorganic blend of microbes then travels within the treated wastewater to the clogged soil and starts to digest the Biomat, which is clogging the soil pores. Sludgeless Treatment Systems are being designed by us, which allows the solids to settle at the bottom of a tank (after Biodegradation). In the presence of Microbes and Dissolved Oxygen in Water, the sludge is further degraded into Carbon Dioxide and Water, leaving behind dead Bio Mass.

...more

Fluidised Media Bioaugmented service

basic principle the bioreactor works on the principle of attached growth. the bioreactor tank consist of fluidised media. Media is in suspension- specific gravity media fluidization- by virtue of hydraulic currents set by aeration. specifically developed microbial culture is used for the development of biomass required for oxidation of organic load. the micro organism attach themselves to the fluidised media and grows upon it. by use of the media and due to high population of micro organisms it takes little time to degrade the waste. our range of product include submersible jet aerators, clarification system, filtration units, u-v systems, flash mixers and flocculators, dosing tanks and pumps, filter press, fluidised media, etc fmbbr sewage treatment system has the following basic advantagesover normal biological processes.1. Normal intrinsic bacteria from within the sludge and sewage is notadapted to shock loads, ph and temperature variations. Weprovide a special bacterial culture biorganic to tackle all sorts ofwastewater. This reduces sludge, consumption of power, due tolesser aeration needs and a more comprehensive treatment. Ourculture contains 56 strains of bacteria and fungi. Every milli litercontains a million colony forming units.2. The use of plastic media (fluidised) ensures active growth ofbacteria and higher biomass, resulting in lower retention period totreat the sewage. With proper growth there is no need for sludgerecycling as is normal.3. Installation of submersible jet aerator(s). This is an aeratorspecifically designed for wastewater treatment. It imparts a veryhigh oxygen transfer rate for every horse power it transfers 40 kgsper day. This is a highly energy and cost efficient system, made initaly austria and is of stainless steel with a sacrificial anode toprevent damage to the submerged system. The entire system isfloating and can be moved as required.4. The installation of an ultra violet dosing is the ultimate in tertiarytreatment. It removes all pathogens and most odour from thetreated water so that it can be put to several reuses, such asgardening, washing of paths and roads and even ground waterrecharging to replenish the water table.line of treatment:the sewage will come to the equalisation tank. Some solids will graduallysettle in the equalisation tank. The settled solid is periodically removedfrom the bottom and is taken to the slurry holding tank.the waste water then moves to the bioreactor tank where it is oxidized bybacteria in the bioreactor tank where continuous aeration and mixing iscarried out with the help of the jet aerator. The bacterium, providedattaches to the plastic media and grows upon it. The high populationserves to biodegrade the organic solids in the effluent.the sewage then passes through the tube settler. The sludge settles at thebottom of the settler and is removed while clear treated wastewatermoves out from the top. The settled sludge is taken to the slurry holdingtank.the treated water from the settler is then fed to the activated carbonfilter for final tertiary treatment. The activated carbon filter is periodicallybackwashed and the back wash is taken to the slurry holding tank.the waste within the slurry holding tank is filtered through the filter pressexcess supernatant liquid, within the slurry tank, is discharged back intothe equalisation tank for re treatment.special features of our system:use of engineered micro organisms for bioaugmentationuse of maintenance free aerators, which transfer nearly100% more oxygen to wastewater per motor h.p. (ascompared to other systems).

...more

septic tank treatment services

wastewater treatment services

Introduction to Biotech Services

We present below a link to a presentation of our services and business in the field of environment protection and effluent treatment.

...moreOpening Hours