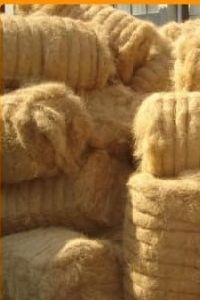

coco fibre

Get Price Quote

10 Kilogram (MOQ)

White Coco Fiber

Get Price Quote

1 Ton (MOQ)

Manvi Agro Industries is a specialized White Coco Fiber Supplier Company offering quality products. Our white coco fibre is derived from coconut husks, offering the highest quality and fully renewable material. Superior Quality White Coco Fiber Thus, being a prominent White Coco Fiber Manufacturer, we guarantee that the product is pure and adheres to the specified quality. Our white coco fibre has high tensile strength and durability while being environmentally friendly and suitable for many uses. Wide Range of Applications The coco fibre white that we sell is multi-purpose and can be applied in various fields. It is perfect for: ● Horticulture and agriculture ● Erosion control ● Filling of the Upholstery and mattresses ● Manufacture of rope and twine Commitment to Sustainability At Manvi Agro Industries, respect for the environment is one of our priorities. White coco fiber manufacturing is eco-friendly whereby wastes and unnecessary usage of raw materials are avoided. Being a responsible White Coco Fiber Manufacturer, we always pay much attention to environmental issues. Why Choose Us? Choosing Manvi Agro Industries as your White Coco Fiber Manufacturer guarantees you: ● High-quality, durable products ● Competitive Pricing ● Environmentally friendly practices and environmentally sound procedures ● Excellent customer service To know more about our white coco fibre feel free to browse through our Website or you may directly get in touch with us. For all your white coco fibre requirements, come to Manvi Agro Industries.

Best Deals from Coco Fibre

coco fibre

400 Per Ton

25 Metric Ton (MOQ)

Coco peat (coco-peat), also known as coir pith, coir fibre pith, coir dust, or simply coir, is made from coconut husks, which are by-products of other industries that use coconuts. Coir waste from coir fibre industries is washed, heat-treated, screened and graded before being processed into coco peat products of various granularity and denseness, which are then used for horticultural and agricultural applications and as industrial absorbent. Usually shipped in the form of compressed bales, briquettes, slabs or discs, the end user usually expands and aerates the compressed coco peat by the addition of water. A single kilogram of coco peat will expand to 15 litres of moist coco peat. The Advantage of COCO PEAT: The properties of Coco Peat make it resistant to bacterial and fungal growth. Coco Peat holds water rather than shedding it like traditional peat does! It holds 8-9 times its weight in water. Coco Peat has the ability to store and release nutrient to plants for extended periods of time. It also has great oxygenation properties which is important for healthy root development. Enhanced root penetration Coco peat extends the life of compost. Contains natural substances and beneficial microbes for plant growth The coco peat tends to expand in its volume, (i.e..,) Four to five times from its original volume provided. It has a pH of 5.2-6.8 which is neutral to slightly acidic. This makes it great for alkaline garden soils. Easy to use – Just put your compressed Coco Peat brick in a container, add 4 quarts of warm water and let it sit until the water is absorbed, fluff it up and you are ready to use Coco Peat! Coco Peat can be reused for up to 4 years. Coco Peat is very slow to disintegrate; it only begins to break down when it is 10 years old, long term benefits. It is very light and easy to handle. It can be combined with any of the normal ingredients and use as a mixer or a stand-alone product. Weed free, pathogen free, insect free and odourless Excellent medium for growing worms. It’s actually good for them and increases worm growth by 25%. Has high air-filled porosity Much lighter than soil Mixed with sand, compost and fertilizer to make good quality potting soil Environment friendly and non-hazardous How to use coco-peat: The normal use of coco-peat in foreign country are the use of coco-peat block form. Then if we need to expand the whole block later immerse the block in a large tub capable of holding at least 25 litres of water. Remove the wet expanded cocopeat that floats in the water. While continuing to add water to the tub till the complete block is expanded. The cocopeat in the bag are light in weight and easily transported to the nursery area or rain shelter greenhouse. For a large grower who needs to expand large number of cocopeat blocks, place the cocopeat blocks vertically with about 1 ft between them. Spray water from a hose on the cocopeat blocks while working on the blocks with hand to expand them into moist cocopeat. Another method is to use machinery to crush the block into powder and then use the dust. The use of low compression cocopeat for absorption purposes, normally we advise the farmers to simply break and crush the block into powder in the palm of your hand. This method practical for those fragile cocopeat either for locally produced cocopeat or imported cocopeat. The use of cocopeat for potting mix we advise the user to mix the expanded cocopeat with leaf mould or homemade organic manure in the ratio of 1:1. Add red soil or sand in small quantities for large plants, otherwise the cocopeat will not be able to hold the weight of the plants as they grow. Red soil tends to compact over time (despite the cocopeat), so take care not to mix more than one third of the mix. For germination, mix cocopeat, leaf mould and sand in the ratio of 1:1:1. If you are using commercial organic manure, it would be better to mix cocopeat and organic manure in the ratio of 10:1 as commercial organic manures are often of high strength. If the cocopeat are the hydroponics medium, the techniques for hydroponics it is better to thoroughly wash and buffer the cocopeat before use as most of the nutrient formula available on the web are not meant for growing in coir. First expand the cocopeat block as instructed earlier. Wash the expanded cocopeat in a large tub of soft water for a few minutes. Drain the water and repeat the process. If the cocopeat you bought is unwashed, you will have to repeat the process a couple of times more. Dissolve calcium nitrate in water in the ratio of 1 g per litre and allow the cocopeat to soak in the solution for 12 hours. Drain any remaining solution and wash the cocopeat again in soft water a couple of times. The cocopeat is now ready for use as a hydroponics medium. The use of cocopeat replaces the conventional use of topsoil as planting media. More new agriculture technologies are adapted and towards vertical farming system to increase per square meter productivity. The sowing technology today depends on cocopeat and peat moss as efficient and practical medium for seedling preparation.

Brown Coco coir Fiber

15 - 25 Per Kilogram

1000 Kilogram (MOQ)

Good quality brown coco fiber

coco fibre

5 - 6 Per Kgs

100 Tons (MOQ)

We are supplying good quality of coco fibres

Coco Fiber

Get Price Quote

100 Kilogram (MOQ)

We are the main supplier of this product.

Coco Fiber

Get Price Quote

We are the main supplier of this product.

coco fibre

Get Price Quote

The fibrous husks are soaked in pits or in nets in a slow-moving body of water to swell and soften the fibres. The long bristle fibres are separated from the shorter mattress fibres underneath the skin of the nut, a process known as wet-milling. The mattress fibres are sifted to remove dirt and other rubbish, dried in the sun and packed into bales. Some mattress fibre is allowed to retain more moisture so it retains its elasticity for twisted fibre production. The coir fibre is elastic enough to twist without breaking and it holds a curl as though permanently waved. Twisting is done by simply making a rope of the hank of fibre and twisting it using a machine or by hand. The longer bristle fibre is washed in clean water and then dried before being tied into bundles or hanks. It may then be cleaned and 'hackled' by steel combs to straighten the fibres and remove any shorter fibre pieces. Coir bristle fibre can also be bleached and dyed to obtain hanks of different colours.

coco fibre

Get Price Quote

We are a quality driven and make sure that the offered lot is prepared using the premium grade raw material. Also, we make sure that it is sourced from the certified vendors. After the goods are sternly examined by the experts, the picking, checking, labeling and packing commences in the substantial warehouse. Sprawling over a large area, we ensure that the goods are packed with utmost proficiency.

coco fibre

1 - 200 Per Kilogram

22 Ton (MOQ)

coco fibre

Get Price Quote

We are offering coco fibre. Brown coir is used in floor mats and doormats, brushes, mattresses, floor tiles, twine and sacking.pads of curled brown coir fibre, made by needle-felting are shaped and cut to fill mattresses and for use in erosion control on river banks. A major proportion of brown coir pads are sprayed with rubber latex which bonds the fibres together (rubberised coir) to be used as upholstery padding for the automobile industry. The material is also used for insulation and packaging. The major use of white coir is in rope manufacture. Mats of woven coir fibre are made from the finer grades of bristle and white fibre using hand or mechanical looms. White coir also used to make fishing nets due to its strong resilience to salt water

Coco Fiber

Get Price Quote

We, as a prominent Supplier and Exporter, present Coco Fiber. It is procured from the vendors who are willing to deliver absolute quality on a consistent basis. It is known for its hygienic processing and high nutritional value. Get the impeccable quality on offer delivered at your doorstep. We make this excellence available at cheaper rates in attractive and hygienic packing.

coco fibers

Get Price Quote

Customers highly prefer us because of our practice of delivering the orders in an organized condition and on time. We keep a stern check while the product is being developed to make sure that we deliver only flawless range.

coco fibre

Get Price Quote

Coir fibre or Coco fibre is the by-product of coconut coir processing. It is extracted from matured green and brown coconut husks. It is then processed into finest fibres which are utilized for the manufacture of mattresses, door mats, sacking etc. Coconut fibres are of two types: white and brown fibres. White fibres are processed from fresh green coconut and it’s finer than brown fibre. In geo-textile manufacture, they are used for bank stabilization and soil re-vegetation.

coco fibre

Get Price Quote

Coir is a natural Fibre extracted from the husk of coconut and used in products such as floor mats, doormats, brushes, mattresses, etc. Technically, coir is the fibrous material found between the hard, internal shell and the outer coat of a coconut. Other uses of brown coir (made from ripe coconut) are in upholstery padding, sacking and horticulture. White coir, harvested from unripe coconuts, is used for making finer brushes, string, rope and fishing nets.Coconut coir Fibre, or in world trade is known as Coco Fibre or Coir Fibre. It is a byproduct of coconut coir processing. Traditionally coconut Coir Fibre is only used for brooms, mats, ropes and tools of other household. Technological developments, physico-chemical properties of Fibres, and consumer awareness to return to natural materials, made of coconut coir Fibre utilized as industrial raw materials carpet, upholstery and dashboard of the vehicle, mattresses and Pillows.

coco fibre

11 - 14 Per Kilogram

10 Tons (MOQ)

Coco Fiber

10 - 15 Per Kilogram

1 Ton (MOQ)

Decorative Coco Fibre

Get Price Quote

500 Piece (MOQ)

coco fibre

12 - 15 Per Kilogram

50 1 to 50 (MOQ)

Coco fiber is thick brown colour sun dry

Coconut Coco Fibre

Get Price Quote

coco fibre

Get Price Quote

We are leading exporter of coir fibre bales from india , If you need this product , Please contact us for domestic and international sales

coco fibre

Get Price Quote

Coco Fibre is a by-product of coconuts and is extracted from the inner surface of the coconut. We export and supply high quality Coco Fibre to our esteem clients across the globe. We source Coco Fibre from the reputed and reliable vendors only. We offer customized packaging of Coco Fibre as per customers demand. Attributes : Eco friendlyBio degradableUsed in various applicationsStrong fiber

coco fibre

Get Price Quote

-1 Metric Ton (MOQ)

Good quality Coco Fibre available

coco fibre

Get Price Quote

We are offering coco fibre. J k coco make very best quality coco fiber

Coco Fiber

30 Per Kilogram

coco fibre

Get Price Quote

Common Name : Coco Fiber Type of Fibers : White Fiber & Brown Fiber Scientific Name : Cocos nucifera and Arecaceae (Palm) Size of Length : 5Cms to 10Cms 20% 10Cms to 25Cms 80% Packing Method : 100Kg Bales with plastic straps Moisture Level : Below 15% Special Quality : 100% without Braided Impurities : Less than 3% Loading Capacity : 188 Bales per 40� Container

coco fibre

10 - 15 Per Kg

50 Ton (MOQ)

Coco fiber

coco fibre

20 Per Kilogram

1 Ton (MOQ)

Coir fibre is extracted from coconut husk. Husk contains 1/3 fibre and 2/3 coir pith. We are extracting coir fibre from various mechanical methods, like combing and beating. The coir fiber is relatively water-proof and is one of the few natural fibers resistant to damage by salt water. Brown coir is harvested from fully ripened coconuts. It is thick, strong and has high abrasion resistance. It is typically used in mats, brushes and sacking. Mature brown coir fibers contain more lignin and less cellulose than fibers such as flax and cotton, Fresh water is used to process brown coir

coco fibre

Get Price Quote

10 Metric Ton (MOQ)

coco fibre

Get Price Quote

Coco Fibre is extracted from the coconut's outer husk. Depending on the freshness and maturity of coconut’s husk, extracted fiber’s color, quality and purpose are differed. We deal in Coco Fibre of three grades. All of them are manufactured from the finest coconut husks, which are chemically treated for impurities.Grades : Grade A Golden Yellow Coir Fibre Grade B Golden Brown Coir Fibre Grade C Golden Brown Coir Fibre Uses : Twine making Insulation and Packing Soil erosion Control