Compressed Air Dryer

4,000 - 50,000 Per Each

1 Each (MOQ)

We manufacture high quality compressed air dryer that is developed from optimum quality base materials. Adopting latest technology and technical expertise, we have created finest heatless compressed air dryer that ensures high efficiency and durability. Moreover, it requires low maintenance. We are listed in the apex of most prominent refrigerated compressed air dryer exporters, based in india. Our compressed air dryer is available in both regular as well as irregular sizes. Some of the essential features of our dryer are robust construction, anti-corrosive, etc. The compressed air dryer is the simplest form of air dryer that can attain a dew point of -40â°c. Wet air passes through the chambers in upward direction through the desiccant. Drying of air takes place through absorption. Subsequently, dry air passes though chamber I to check valve assembly and to the after filter application area. In chamber ii, the desiccant is already wetted that is simultaneously regenerated. It is further depressurized in the atmosphere in downward direction through purge valve and needle valve. After the refrigeration is over, the purge is closed and the tower gradually repressurized to line pressure that initiates a smooth changeover. The 5 minutes of dying period render an efficacious dew point to -40â°c. For a perfect repressurization, approximate 60 seconds are required.

heatless type air dryer

Get Price Quote

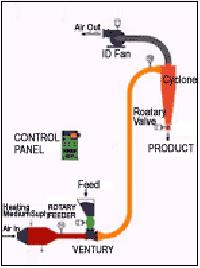

The heatless type dryer is designed to take advantage of the natural tendency to dessicant to established equilibrium with their surrounding and can deliver super dry compessed air. these type of dryers are the most economical and dew poins upto (-)40 °c are easily achieved. such dryers are mostly preffered for flow upto 500 cfm.Features: Excellent functionality High efficiency Superior performance Robust construction Specifications: Capacity: 20 CFM to 500 CFM Dew Point: -40 to -60 deg C ADP Purge Loss: 12-15 % Process: In this dryer two desiccant towers are used. While one tower is in drying, second tower undergoes regeneration simultaneously. Part of dry air coming out from tower in-line goes for regeneration of the second tower. Tower changeover takes place at every 5 minutes by a sequence controller mounted in control panel.

Best Deals from Compressed Air Dryer

Refrigeration Compressed Air Dryer

58,000 Per Piece

1 Piece (MOQ)

Desiccant Air Dryer

Get Price Quote

1 Piece (MOQ)

Morish India heatless dryer system represents optimized resource efficiency. Our desiccant dryers absorb moisture from the air stream and onto a desiccant material in reversible process. They produce low dew points (up to -60 degree Celsius), so they are a good choice when processes require extremely dry air in industries like pharma, paint, biotech laboratories etc. USP: Clear overview for all operating statuses gives a hassle-free operation!!HIGHLIGHTS Compact Design Low Pressure Drop Consistent Dew Point Energy Efficient Reliable Ease of Installation Environment Friendly Least Required Maintenance

Desiccant Air Dryer

Get Price Quote

1 Piece (MOQ)

Refrigerated Air Dryers

Get Price Quote

Refrigerated Air Dryer

Get Price Quote

Compressed air with saturated water vapor enters the dryer’s pre-cooling device, in which, the entered hot air is cooled down by the outgoing cold air partly, thus reducing the load on the system (this process is pre-cooling). Pre-cooled air enters the evaporator. Here, heat released by the air is absorbed by media and the air reaches the pre-set temperature (2 ~ 4oC). After being cooled, the water vapor in the air condenses into droplets and is separated from the air by steam separator and then flows out of the dryer through automatic drainer. Leaving the separator, cold air enters into the pre-cooling device’s shell side for heat exchange with hot air in the inlet and leaves the dryer after being heated to a temperature about 10oC lower than that of the inlet air. This reheating prevents the second moisture condensation in the outside exit air pipeline and downstream pipeline, increases the energy of the air and improves the effectiveness. In addition, after passing through the dryer, solid dust of over 3μ in the compressed air is all filtered, and the air source quality reaches the clean and dry requirements. Salient Features Economical in power consumption in comparison with other type of dryers for equivalent dew point. Innovative Heat Exchanger ensure max. Heat transfer & low pressure drop. In built safety devices for compressor, condenser etc. Consistent Dew point over wide range of flows. Simple design, easy access to all parts requiring almost no maintenance. Modular skid mounted unit in robust industrial cabinet is prewired and piped. Inbuilt air, electrical & drain connection. The dryer is ready to start saving your money. High quality product due to stage wise inspection & testing before dispatch.

desiccant air dryers

Get Price Quote

Desiccant air dryers Heat exchangers maintain high degree of heat exchange efficiency and lower pressure drop through out life of dryer. Consistent degree of dryness over a wide range of flows and operating conditions.

Refrigerated Air Dryers

Get Price Quote

Having the support of an expert team, we have successfully developed Refrigerated Air Dryers. These dryers worked on the principle of compressed air with saturated water vapor that enters the dryer's pre-cooling device. This air is cooled down with outgoing cold air, thus reducing the load of the system.

Refrigerated Air Dryer

Get Price Quote

Heatless Air Dryer, Membrane Air Dryer, Energy Saving Design, Reduced Power Consumption, Robust in high temperature environments.

Compressed Air Dryers

40,000 Per Number

3 Number (MOQ)

Heatless Air Dryer

Get Price Quote

We manufacture and export an extensive range of heatless type air dryers, which is a simplest form of dessicant type gas or air dryer (drier). These are use to achieving a dew point of -40?c or excellent for compressed air systems and other gas and air dryer (drier) applications. There is no increase in the effluent gas temperature and the desiccant beds remove oil in its vapor form.

Desiccant Resin Dryer

Get Price Quote

We are offering drying of plastics enhances quality of molding. Moisture content in plastics adversely affects the quality of molding. Excessive moisture in resins leads to products with unacceptable sturdiness, silver streaks and holes. Dryers serve to remove moisture from resins to prevent molding of such defective products. At times, the increase of temperature is used to enhance the plasticity during molding.

Refrigerated Air Dryer

Get Price Quote

We offers a wide range of refrigerated air dryer which is used to remove moisture from compressed air by reducing the temperature. In this dryer compressed air is passed through a heat interchanger where cold refrigerant at around 3°c is passed through the other side of the heat interchanger. At this temperature most of the moisture is condensed which is then separated and drained out in moisture separator.

Desiccant Compressed Air Dryers

Get Price Quote

Desiccant Compressed Air Dryers, Compressed Air Dryer, ammonia crackers

Heatless Air Dryers

Get Price Quote

Heatless Air Dryers, Air Dryers, gas dryers

Heatless Air Dryers

Get Price Quote

Heatless Air Dryers, industrial air dryers, Refrigerated Air Dryers

Refrigerator Air Dryer

Get Price Quote

Refrigerator Air Dryer, oil free compressor, Screw Air Compressor

Refrigerated Air Dryer

Get Price Quote

Refrigerated Air Dryer, water cooled scroll chiller