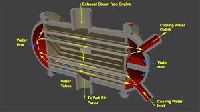

Shell And Tube Type Condenser

Get Price Quote

Shell & Tube Type Condenser Drycool with its exceptional thermal performance and fatigue resistance, the compact-sized DRYCOOL Shell & Tube heat exchanger opens up a whole new world of possibilities. Designed for use with liquids, gases and two-phase mixtures at pressures up to 100 bar (1450 psi), in both PED and ASME, and at temperatures up to 450°C (842°F), DRYCOOL Shell & Tube is suitable for a wide range of aggressive media. The benefits of DRYCOOL Shell & Tube: Robust design and minimized maintenance ensure maximum uptime Superior thermal performance means maximum heat recovery using minimal heating and/or cooling media, which cuts fuel consumption, energy costs and environmental impact Small footprint and light weight minimize installation, operating and maintenance costs Gasket-free construction means high security against leakage Easy to install and maintain due to multipass design Compact solution with a small footprint The features of DRYCOOL Shell & Tube: Patented roller coaster plate pattern ensures exceptionally high thermal efficiency. Unique cut-wing plates allow for multi-pass design. Fully welded design allows for high operating pressure and optimizes resistance to fatigue. Robust design and minimized maintenance ensure maximum uptime. Distribution pipes run through the plate pack, relieving stress on the pack itself.

Mild Steel Air Cooled Condenser

10,000 Per Piece

1 Piece (MOQ)

Best Deals from Condensers

Shell & Tube Type Condenser

Get Price Quote

Shell & Tube Type Condenser is used to condense the vapor emerges out during the operation. It has been designed with tested raw materials to suit the capacity requirements. It mainly works through condensing the vapors flow through tubes where they are treated with cooling water over external surface. It is manufactured at our state-of-art manufacturing unit with the assistance of latest technology and machinery. High grade materials are used for fabricating this equipment.

Surface Condenser

Get Price Quote

The Company mainly manufactures two categories of products: equipment for power plants, including pulverized coal-fired (PC) boilers, heat recovery steam generators (HRSGs), surface condensers, feed water heaters, closed cooling water (CCW) heat exchangers, boiler coils, boilers, deaerators and others, and equipment for steel plants, including recuperators, coke dry quenching (CDQ) boilers, waste heat recovery systems, steel making plant boilers, reactors, oxygen plant heat exchangers and others.

multi flow condenser

Get Price Quote

multi flow condenser, bus air conditioner, Chlorine Compressors, BUS AC

Air Cooled Condenser

Get Price Quote

Air Cooled Condenser, Copper Elbows, oil pressure switch

dc condensor

Get Price Quote

dc condensor, Fan Motor

wire condenser

Get Price Quote

wire condenser, Capillary Tube, Brazing Rod, Water Cooler, Steel Tube

Condenser

Get Price Quote

Condenser, melter, Juice Heaters

Condensers

Get Price Quote

Condensers

Mica Condenser

Get Price Quote

Mica Condenser, fabricated mica products, Mica Washer, Mica Thins

car ac condenser

Get Price Quote

car ac condenser

Condensers

Get Price Quote

Condensers, Auto Radiator, bus air conditioner, Marine Chilling Compressor

Shell & Tube Type Condenser

Get Price Quote

Shell & Tube Type Condenser, water cooled scroll chiller

Shell & Tube Condensor

Get Price Quote

Shell & Tube Condensor, Air Dryer, HP Feed Water Heater

Tube Condenser

Get Price Quote

Tube Condenser, ventilation contractors, Fan Coil Unit