Conveyorised Acid Draining Machine

Get Price Quote

Once Battery is cut and now only Plates with separator are there in Plastic container. There may be acid in the Battery Container still. Battery will drop in upside position, manually assisted. Container can be picked up and placed at a side or drop in Plastic Crusher. Battery Plates and Separator can be transported to Plate Crushing Machine. Acid will drop in tank. Acid Proof Tank is in-built in the attachment. Lead Oxide Dust and small grid parts will precipitate. Acid can be pumped out, if connected to another tank. Lead Sludge can be charged in furnace.

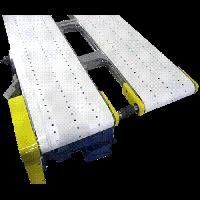

Roller Conveyor

80,000 Per Piece

Best Deals from Conveyors

Conveyor Components

Get Price Quote

The Conveyor Components range from RS Components will meet any material transportation requirement. You will find ball transfer units, conveyor rollers, turntables and tracks as well as a full range of guides, rails and accessories from top brands including Interroll and ALWAYSE.

Fruit and Vegetable Sorting Conveyor

Get Price Quote

We also manufacture tailor made sorting cum material handling conveyors for Foods Products / Fruits & vegetables.The Conveyor manufactured by us are of of SS 304 / SS 316 with Food quality belts. In some case the SS wire knit conveyors are also used depending upon the requirement

Weigh Feeder

Get Price Quote

1 Piece(s) (MOQ)

• it can be operated from any location viz: local panel, main panel or control room. • very sturdy and rugged frame design • quick belt change mechanism ensures very low down time. • designed for capacities from 1 to 2000 tph • microprocessor based dedicated weigh feeder controller. • accuracy as high as + 0.5% on the set point .

Smart Conveyor

Get Price Quote

1 Piece (MOQ)

Details Precision positioning conveyors. Multiple station assembly conveyors. Automatic product identification and distribution conveyors. Precise positioning Oval slat conveyors. Auto start stop conveyor systems according to product availability. Conveyors with printing batch data arrangements. Conveyors with barcode protection and ejection systems

SPOT CAKE DEPOSITOR WITH CIRCULAR CONVEYOR & MUFFIN CONVEYOR

Get Price Quote

Technical Features - The machine has three attachments. - a) A handgun for manual operation. - b) A muffin conveyor to deposit into trays. - c) A circular conveyor for depositing into different shaped moulds - The weight of the Cake can be between 10 to 500g grams. - The machine is also fitted with a PLC and computer from where the operator can feed the dosage & store them for future quick changeovers. - The unique advantage of the machine is that it can handle big chunks of Fruits & Dry-fruits in bigger cakes on a circular conveyor. - The low height, Large Capacity of the better hopper makes it convenient for the operator to tilt the Full batch into the hopper manually. There is no need of transfer pump.

Cleated Conveyor Belts

Get Price Quote

We believing in providing the right and suitable cleated conveyor belts, as it helps them to use it in an effective way. Our cleated conveyor belts are produced based on the requirement, which helps people to use it for a longer span of time. We are engaged in producing awide range of cleated belts, which can be used in different places.

Infeed Conveyor With Big Hopper

Get Price Quote

stainless steel belt

Get Price Quote

Corrosion resistant, temperature resistant, used for conveying the material in rugged conditions Excellent Anti-static, to prevent electricity caused by conveying. Not easy to make the dust, used in the cleanroom of electronic and chemical industry. Smooth surface, suitable for the stay in the course of conveying Easy to clean, neat and hygiene.

TRIPLE STAGE CUTTING conveyor machine

Get Price Quote

This machine has a automatic conveyor. Battery is placed on the conveyor. Width of Battery, need not to be set. It can accommodate Battery up to Max. Width of 305mm. Most of Batteries are less than this. This machine has three Blades for Cutting. Cutting heights of all the three blades can be set at independent heights by turning Rotary wheel. This wheel is visible in picture of machine. Scale is provided to set the height of cutting from bottom. Conveyor takes the Battery into machine for cutting. First Cutting is set above lid so any battery which has more height than normal automotive batteries like Standby Batteries i.e. IT-500, Jumbo etc. will be cut and that portion ejects out from first window. Second cutting is set normally at sealing line of automotive battery lid and third cutting is set below strap.During Cutting of Battery dust is confined inside of covers because cutter is enclosed. Max. Of Automotive Batteries have approximately same height, say +-10 mm. Cut Lid ejected out of first window and Strap portion of battery ejects out form second window. Remaining Battery will come out of machine on Conveyor. Machine can be provided with wheels so machine is used to unload battery at the same time cutting is performed.This saves exposure of workman from Lead Dust; increases efficiency of organization reduces lead time as well as increases liquidity of Funds. Plastic Containers can be sent for immediate disposal/recycling facility. Lead Dust is confined inside enclosure at the same time water jets are provided by pre-fitted Pump. Water is collected in the bottom tank. This helps to separate Plastic Dust from Lead dust. Plastic dust floats and lead dust is precipitated at the bottom. Hence it becomes environmentally Sound Method to cut the Battery for further separation. Remember this Cut Battery can directly go to another attachment; we call it Acid Draining Attachment. Details of this attachment are mentioned below. This machine is suitable for normal quantity of Batteries or by small smelter with normal budget. Power required: 415V 3 phase, 12 Kw approx. Belt made of : Nylon

Hot Air Tray Dryer Oven

Get Price Quote

We are offering hot air tray dryer oven. Hot air tray dryer oven for uniform circulation of hot air in the drying chamber, complete with motor. The thermostate, a x v meter, starter, indicator lamp, contractor of standard make. hot air tray dryer oven- technical specifications capacity trays width depth high heat load fan motors 6 54* 21* 23* 3kw 1/4h.p. 12 54* 21* 42* 5kw 1/2h.p. 24 54* 37* 42* 5kw 1/2h.p. 48 78* 40* 74* 7.5kw 1h.p. 96 134* 40* 74* 15kw 2h.p. 192 134* 76* 74* 30kw 4h.p. standard tray size ss 32" x 16" x 11/4

Vacuum Conveyors

Get Price Quote

Vacuum Conveyors, Flat Transmission Belts, conveyor timing belts

Screw Feeders

Get Price Quote

Screw Feeders, Automatic Pouch Packing Machines, Outfeed Conveyor

Automation Equipment - Dry Steel Belt Conveyor

Get Price Quote

Automation Equipment - Dry Steel Belt Conveyor

Screw Feeders

Get Price Quote

Screw Feeders, Automatic Stick Pack Machine

Vacuum Oven

Get Price Quote

Vacuum Oven, Laboratory Instruments, laminar flow cabinets, Microscopes

Pneumatic Conveying System

Get Price Quote

Pneumatic Conveying System