PRECITURN Hi-Cut Precision Lathe Machine

Get Price Quote

Since 25 years PRECITURN Lathe Machine is well-accepted for its Rigidity, Ruggedness & Reliability. Our Lathe machine is popular brand for its persistent accuracies and low maintenance. More than 25000 users in India and abroad are getting benefits from our machines. FeaturLathe Machinees (Series P350HC & P400HC): *Spindle mounted on taper rollers bearings *Bed design with interior pyramid ribs and flame hardening for both flat and V-way *Head stock material is 20Mn Cr5. Which is heat treated and ground *Splash lubricated universal gear box for feed *Fully enclosed apron with oil sump for lubrication and a slipping clutch is provided for over load protection *The cross slide has wide seating on the saddle for rigidity and long life. The key Technical Features: *Swing from 350 to 600 *Center Distance from 750 to 3000 *Precision ground &Hardened Bed ways (>500 BHN) *Removable Gap Piece *Dynamically Balanced Main Spindle *Headstock Gears Ground with Low Noise *Tailstock locked by eccentric wheel *Feed rod and lead screw interlocked *Main spindle supported at 2 points with precision taper roller bearings *Big spindle bore O52mm *Safety torque limiting device for lead screw Safety overload clutch for feed rod *Rapid traverse ( optional )

Automatic Round Wire Cutting & Stripping Machine

235,000 Per Piece

1 Piece (MOQ)

Best Deals from Cutting Machine

Double Shaft Cutting Machine

1,200,000 - 1,500,000 Per Unit

1 Set (MOQ)

Triple Stage Battery Cutting Machine

Get Price Quote

The Triple Stage Battery Cutting Machine, which we offer, is manufactured in confirmation to the established industrial standards. We are amongst the reliable Sources to source these Triple Stage Battery Cutting Machines. Also, this Triple Stage Battery Cutting Machine is manufactured using the leading-edge technology. Details This machine has an automatic conveyor Battery is placed on the conveyor Width of Battery, need not to be set It can accommodate Battery up to Max. Width of 305mm (Most of Batteries are less than this) This machine has three Blades for Cutting Cutting heights of all the three blades can be set at independent heights by turning Rotary wheel (This wheel is visible in picture of machine) Scale is provided to set the height of cutting from bottom. Conveyor takes the Battery into machine for cutting. First Cutting is set above lid so any battery which has more height than normal automotive batteries like Standby Batteries i.e. IT-500, Jumbo, etc. will be cut and that portion ejects out from first window Second Cutting is set normally at sealing line of automotive battery lid and third cutting is set below strap. During Cutting of Battery dust is confined inside of covers because cutter is enclosed. Max. Of Automotive Batteries have approximately same height, say +-10 mm. Cut Lid ejected out of first window and Strap portion of battery ejects out form second window. Remaining Battery will come out of machine on Conveyor. Machine can be provided with wheels so machine is used to unload battery at the same time cutting is performed. This saves exposure of workman from Lead Dust; increases efficiency of organization reduces lead time as well as increases liquidity of Funds. Plastic Containers can be sent for immediate disposal/recycling facility. Lead Dust is confined inside enclosure at the same time water jets are provided by pre-fitted Pump. Water is collected in the bottom tank This helps to separate Plastic Dust from Lead dust. Plastic dust floats and lead dust is precipitated at the bottom. Hence it becomes environmentally Sound Method to cut the Battery for further separation. Remember this Cut Battery can directly go to another attachment; we call it Acid Draining. Situated in Noida (Uttar Pradesh), we have built a wealth of reputation for manufacturing, supplying and exporting the superior-grade Triple Stage Battery Cutting Machines across the globe. Attainable at market-leading prices, the Battery Slicer (Triple Stage) is distinguished for its hassle free functions for a long span without much upkeep. For utmost gratification of the clients, we dole out quality-tested Battery Cutting Machines in tailored specifications. Specifications : Out Put Capacity : Two to Two and Half Ton/ Hour. Power Requirement : 16 Kw, 440 Volt, 3 Phases, 50 Hz. Man Power Requirement : Two no. unskilled Labor Operational Expenses for battery Breaking per ton : $ 2.10/ Ton approx Description : This Machine has One Conveyor, Three Cutting Stations with one Bend Saw Blade each. Conveyor is used to feed the batteries into machine and Cuts off batteries at three respective set heights, as set by the operator. Blades are water cooled. After Cutting operation, Cut batteries are transported out of the machine by conveyor. Cut (Sliced Off) Top of battery is ejected out automatically from first window and Connection Strap and part of Container from Second Window and third blade as stand by so during slicing off if one of the blade become blunt then another station is utilized and production is not interrupted. Other option is if Bigger battery with more height is fed then it can be sliced off into four Pieces. Maximum Height of batteries can be fed to the machine is 600 mm and width being 305 mm. Fume are collected and restricted by the Enclosed Body of Machine. No human exposure is involved in Cutting operation. Exposure of acid fumes and lead meet best environmental practices in the world No. Adjustment of Width is required. Operation of Machine : Batteries are placed on the moving conveyor. Top of Batteries is sliced off by high Speed Bend Saw. There is one Bend Saw with height adjustment to set Cutting (Slicing) Height. Height is set manually. Sliced off Lid from first window is ejected out. Then battery moves to second cutting Blade, here Connection Strap and Part of Container is Sliced off which is also ejected out from Second Window. If more height battery is sliced off then part of Plates and Container is also sliced off and Remaining Part of battery is transported by the conveyor to other end of the machine, where it is toppled into Acid Draining Attachment. Output of Machine : Battery Top Connection Strap with Container Part Part of Plates and Container Remaining part of Battery. Acid Drained out in to Acid tank.

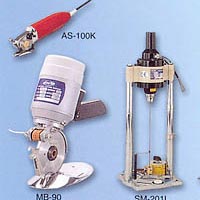

Cloth Cutting Machine

7,800 - 13,500 Per piece

Our company is one of the reliable Suppliers of Cloth Cutting Machines in Noida. The Cloth Cutting Machines provided by us are high quality products procured from trustworthy sources from the major world markets. They are fast and easy to operate. Specialties of Cloth Cutting Machines : Can be used for different types of fabricsExcellent and efficient performanceLong life and highly durableVarious Cloth Cutting Machine Parts and Cloth Cutting Machine Knives also available

Automatic Soap Cutting Machine

170,000 Per Piece

1 Piece(s) (MOQ)

Non Woven Fabric Sheet Cutting Machine

Get Price Quote

We are offering non woven fabric sheet cutting machine, embossing machines, folding machines etc. This machine is suitable for roll materials. It has much functions such as computer control,high speed frequency conversion,fixed length setting,automatic counting and sound light alarm,it is a necessary equipment for roll material cutting. model cyghq-1200 output 20-140pcsmin max.width of fabrics 100-1150mm max.cutting length 30-1000mm bag thickness 20-150g power 380v220v power comsumption 7 kw machine dimension (lxwxh) 3500x1550x1300 mm weight 700kg

Plasma Cutting Machine

Get Price Quote

We are engaged in offering our clients a high quality range of Plasma Cutting Machine. Price Range: Rs 4 Lakh / Unit

Die Cutting Machines

Get Price Quote

Heavy duty platen offered by us have have centralized lubrication system with pump which helps in smooth functioning of the machines. They are available with special electromagnetic clutch and automatic sheet counter that helps in giving in high level of desired output.

TRIPLE STAGE CUTTING conveyor machine

Get Price Quote

This machine has a automatic conveyor. Battery is placed on the conveyor. Width of Battery, need not to be set. It can accommodate Battery up to Max. Width of 305mm. Most of Batteries are less than this. This machine has three Blades for Cutting. Cutting heights of all the three blades can be set at independent heights by turning Rotary wheel. This wheel is visible in picture of machine. Scale is provided to set the height of cutting from bottom. Conveyor takes the Battery into machine for cutting. First Cutting is set above lid so any battery which has more height than normal automotive batteries like Standby Batteries i.e. IT-500, Jumbo etc. will be cut and that portion ejects out from first window. Second cutting is set normally at sealing line of automotive battery lid and third cutting is set below strap.During Cutting of Battery dust is confined inside of covers because cutter is enclosed. Max. Of Automotive Batteries have approximately same height, say +-10 mm. Cut Lid ejected out of first window and Strap portion of battery ejects out form second window. Remaining Battery will come out of machine on Conveyor. Machine can be provided with wheels so machine is used to unload battery at the same time cutting is performed.This saves exposure of workman from Lead Dust; increases efficiency of organization reduces lead time as well as increases liquidity of Funds. Plastic Containers can be sent for immediate disposal/recycling facility. Lead Dust is confined inside enclosure at the same time water jets are provided by pre-fitted Pump. Water is collected in the bottom tank. This helps to separate Plastic Dust from Lead dust. Plastic dust floats and lead dust is precipitated at the bottom. Hence it becomes environmentally Sound Method to cut the Battery for further separation. Remember this Cut Battery can directly go to another attachment; we call it Acid Draining Attachment. Details of this attachment are mentioned below. This machine is suitable for normal quantity of Batteries or by small smelter with normal budget. Power required: 415V 3 phase, 12 Kw approx. Belt made of : Nylon

tape cutting machine

149,000 - 150,000 Per Piece

RUBBER CUTTING And BEADING MACHINE

Get Price Quote

We are offering Special Purpose Machines like Rubber Beading and Cutting Machine for operations like turning, milling, boring, drilling, tapping, grinding etc Rubber Beading And Cutting Machine We are engaged in manufacturing Special Purpose Machines specially designed for high production rates with consistent quality. These machines are engineered to provide greatest precision in the process. Our machines can be used for almost all metal cutting operations like turning, milling, boring, drilling, tapping, grinding etc. Special purpose machines find application in diverse industries like automobile , electrical, pipes & fittings, etc.

horizontal cloth cutting machines

Get Price Quote

horizontal cloth cutting machines, precision cloth cutting machines

Wire Cutting Machine

Get Price Quote

Wire Cutting Machine, Soldering Machine, Crimping Machine

foil cutting machine

Get Price Quote

Cnc Wire Cutting Machine

Get Price Quote

Cnc Wire Cutting Machine, CNC Machine, electric discharge machining

Inspection Cutting Conveyor Machine

Get Price Quote

For feeding, inspection, preparation and cutting of fresh fruits or vegetables. Available from 1 to 10 MT/hr feed capacities and in one to three tier models having 6 to 24 work stations.

cutting off machines

Get Price Quote

Master gratings pvt. Ltd. Is offering cutting off machines is provided with high speed rotating spinner that has five adjustable dies.

Sheet Cutting Machine

Get Price Quote

Paper Lamination Machine

Get Price Quote

we are highly reckoned for manufacturing and exporting a wide range of Paper Lamination Machine. With the help of our highly skilled team manufacture this machine in complete compliance with industry standards using premium quality materials.