Optical Glass Grinding Diamond Wheel

2,700 Per Piece

1 Piece (MOQ)

125x16x3mm@2500/+18% gst&125X18X3 @3400 /+18%..(4/5&6 INCH auto edger quality METAL BOND diamond wheels FOR OPTILINE MACHINE.)SINGLE,DOUBLE,V GROOVE FINE, V-GROOVE COMBINATION,AUTO EDGER D.WHEELS IN 1-10 INCHES ARE AVAILABLE O AS PER ORDER. we 'SKE'are engaged in manufacturing and supplying of METAL BOND DIAMOND WHEELS AND MACHINERY FOR OPTICAL LENS, WATCH GLASS,FLOTE GLASS,MIRROR,PIPE-BOTTLE,CERAMIC STONE,FRP,TUNG/CARB.ET.CUTTING,GRINDING,POLISHING 'SPECIALLY WE ARE MFG ALL GLASS PROCESS MACHINERY 'Owing to its high rigidity and optimum strength, this wheel is highly appreciated by our clients in the market. The offered wheel is manufactured by our team of trained professionals using the finest quality raw material and latest technology. Our provided wheel is used in several equipments and mechanical tools. Features: Optimum strength Highly abrasive Easy installation Additional Information: Item Code: 5ASTD Production Capacity: 1000/MONTH Delivery Time: 2 DAYS Packaging Details: THARMOCOLE

Diamond External Grinding Wheels

1,500 Per Piece

70 Piece(s) (MOQ)

We are staffed with dexterous team members and packaging experts; they ensure that the products are completely safe from the external damaging factors, and this is done by using quality-packaging material. You can choose to make payment through offline and online mediums as per your convenience. We are well versed with all and we ensure that the transaction is transparent.

Best Deals from Diamond Grinding Tool

Diamond Grinding Wheel

2,500 - 3,200 Per Pcs

5 Piece (MOQ)

Diamond Cup Grinding Wheel

510 Per Piece

50 Piece (MOQ)

165mm Diamond Cup Grinding Wheel

1,800 Per Piece

Diamond Grinding Wheel

100 Per NOS

diamond cup grinding wheels

850 Per pieces

5 pieces (MOQ)

Diamond Grinding Wheels

Get Price Quote

We are engaged in offering a huge assortment of Diamond Grinding Wheels that is used for smoothing the edges of hard materials, stones and glass.

Diamond Cup Grinding Wheel

135 Per Piece

diamond grinding disc

90 Per Piece

100 Piece (MOQ)

Cylindrical Diamond Grinding Wheel

Get Price Quote

Providing you the best range of Diamond Grinding Wheel such as Diamond Wheel, Vitrified CBN Points for Internal Grinding, Electroplated Diamond / Cbn Wheel, Vitrified PCD Grinding Wheel, Vitrified CBN Grinding Wheel, Cylindrical Diamond Grinding Wheel and many more items with effective & timely delivery.

Corundum Polishing Lap

350 Per Piece

1 Piece (MOQ)

FEATURES OF CORUNDUM POLISHING LAP: Corundum gemstones are known for their toughness and hardness, which are polished with an even harder material, i.e. diamond abrasives. The polishing lap is made of highest grade RVD diamonds, and of the finest grit, which is ideal for polishing hard gemstones. The diamond compound is already present in the entire layer of the lap uniformly. This means that you do not have to worry about manually applying the polishing compound to the lap. The hardness of the diamond abrasives ensures superior surface polish finish to the hard gemstones, whose polishing can be tricky with alternative polishing laps. To assure sturdiness of the polishing lap while operating, it is backed by a strong aluminium baseplate. The polishing lap is the most productive for hard stones of the Corundum gemstones family. It is ideal for polishing Ruby, Sapphire, and Moissanite. An accurate and balanced experience is essential for precise lapping and hence, our polishing lap is made with perfection such that it provides an absolutely flat and parallel surface for polishing gemstones. Constant and appropriate quantity of flow of water is required to reduce friction between the polishing gemstone and lap. It also works to minimise the frictional heat while working. After prolonged use, the lap needs to be dressed to smoothen and renew the lapidary polishing surface. Usage of a dressing stick is advised for best lapidary polishing. ADVANTAGES OVER OTHER LAPIDARY POLISHING LAP: Our polishing lap is known for its characteristics of easy, fast-paced, and clean lapidary polishing results for hard gemstones. The polishing lap comes with compressed and dense diamond abrasives, which ensure that there is no chipping away of the gemstone while polishing. There is no need for any external lapidary polishing agent, which protects the quality of gemstones from loose polishing agents seeping into gemstones through cracks or nicks. In the long-run, our lap is an economical and cost-effective choice than other lapidary polishing tools available for corundum gemstones. The highest quality of material used to manufacture the polishing lap imparts endurance to the lap and hence, it has longer life for continued better polishing results of corundum gemstones. It has the ability to outperform and provides unsurpassed quality results over other polishing lapidary supplies, providing you wholesome satisfaction. It does not wear away as fast as that of other suppliers of polishing laps. It is easy-to-use and convenient as it can be mounted on to any lapidary polishing machines with arbor hole 1/2”. The depth of the polishing region of the lap is 13.55 mm, which imparts a long-lasting life to the corundum polishing lap. More depth provides you the best lapidary polishing experience as it has more polishing area. USER GUIDE FOR POLISHING LAP: While polishing corundum gemstones, it must be kept in mind that the surface of the lap should be constantly supplied with coolant or lubricator that helps In improving the efficiency of polish and prevents overheating of the lap. Water is an ideal choice and its flow should be adequate to aid in the process of polishing. This combination of diamond abrasives pressed onto the lap is ideal for hard stones belonging to the family of Corundum gemstones such as polishing Ruby or Sapphire. In order to avail best results, you must understand the type of compound or polishing agent being used in the lap. It differs according to the hardness of the gemstones. You may also check out our complete range of polishing laps here to make an informed choice. To effectively polish the gemstone, the stone being polished must be moved across the lap from side to side, keeping it in constant touch with the lap. This helps in maintaining the flat surface of the polishing lap in the long-run. It must be ensured that the least amount of pressure is being applied to the gemstone as it prevents chipping away of the top polished layer of the gemstone. Our suggestion is to maintain the lap’s speed at a moderate level, i.e. at 1800 RPM. Otherwise, high speed may lead to high stock removal. To achieve the finest mirror-like lapidary polish of the gemstone, make sure that the lap is clean after every usage and the gemstone should also be free from dust particles. This carelessness may lead to obtaining scratches on the gemstone. The environment where you are polishing the gemstones must also be free from dust particles to avoid deteriorating the quality of gemstones. Lastly, once the lap needs dressing, It must be done with precision and care such that a plane and flat surface of the polishing lap is obtained. SPECIFICATIONS: Arbor: ½” Diameter: 8” Depth (Polishing Region): ~8mm Overall Depth: ~22mm Ideal Running Speed: 1800 RPM Compound: Diamond SHIPPING INFORMATION: Time for shipping varies depending on the shipping region but usually, it takes a maximum of 5-7 business days to be delivered anywhere in the world, once it’s dispatched. The shipping of our Corundum polishing lap is insured. The lap is manufactured and shipped from India. For International customers, the fees on import duty or customs charges will not be incurred by us. Every country’s customs policies are different and must be considered by the customers on their own. FEATURES OF CORUNDUM POLISHING LAP: Corundum gemstones are known for their toughness and hardness, which are polished with an even harder material, i.e. diamond abrasives. The polishing lap is made of highest grade RVD diamonds, and of the finest grit, which is ideal for polishing hard gemstones. The diamond compound is already present in the entire layer of the lap uniformly. This means that you do not have to worry about manually applying the polishing compound to the lap. The hardness of the diamond abrasives ensures superior surface polish finish to the hard gemstones, whose polishing can be tricky with alternative polishing laps. To assure sturdiness of the polishing lap while operating, it is backed by a strong aluminium baseplate. The polishing lap is the most productive for hard stones of the Corundum gemstones family. It is ideal for polishing Ruby, Sapphire, and Moissanite. An accurate and balanced experience is essential for precise lapping and hence, our polishing lap is made with perfection such that it provides an absolutely flat and parallel surface for polishing gemstones. Constant and appropriate quantity of flow of water is required to reduce friction between the polishing gemstone and lap. It also works to minimise the frictional heat while working. After prolonged use, the lap needs to be dressed to smoothen and renew the lapidary polishing surface. Usage of a dressing stick is advised for best lapidary polishing. ADVANTAGES OVER OTHER LAPIDARY POLISHING LAP: Our polishing lap is known for its characteristics of easy, fast-paced, and clean lapidary polishing results for hard gemstones. The polishing lap comes with compressed and dense diamond abrasives, which ensure that there is no chipping away of the gemstone while polishing. There is no need for any external lapidary polishing agent, which protects the quality of gemstones from loose polishing agents seeping into gemstones through cracks or nicks. In the long-run, our lap is an economical and cost-effective choice than other lapidary polishing tools available for corundum gemstones. The highest quality of material used to manufacture the polishing lap imparts endurance to the lap and hence, it has longer life for continued better polishing results of corundum gemstones. It has the ability to outperform and provides unsurpassed quality results over other polishing lapidary supplies, providing you wholesome satisfaction. It does not wear away as fast as that of other suppliers of polishing laps. It is easy-to-use and convenient as it can be mounted on to any lapidary polishing machines with arbor hole 1/2”. The depth of the polishing region of the lap is 13.55 mm, which imparts a long-lasting life to the corundum polishing lap. More depth provides you the best lapidary polishing experience as it has more polishing area. USER GUIDE FOR POLISHING LAP: While polishing corundum gemstones, it must be kept in mind that the surface of the lap should be constantly supplied with coolant or lubricator that helps In improving the efficiency of polish and prevents overheating of the lap. Water is an ideal choice and its flow should be adequate to aid in the process of polishing. This combination of diamond abrasives pressed onto the lap is ideal for hard stones belonging to the family of Corundum gemstones such as polishing Ruby or Sapphire. In order to avail best results, you must understand the type of compound or polishing agent being used in the lap. It differs according to the hardness of the gemstones. You may also check out our complete range of polishing laps here to make an informed choice. To effectively polish the gemstone, the stone being polished must be moved across the lap from side to side, keeping it in constant touch with the lap. This helps in maintaining the flat surface of the polishing lap in the long-run. It must be ensured that the least amount of pressure is being applied to the gemstone as it prevents chipping away of the top polished layer of the gemstone. Our suggestion is to maintain the lap’s speed at a moderate level, i.e. at 1800 RPM. Otherwise, high speed may lead to high stock removal. To achieve the finest mirror-like lapidary polish of the gemstone, make sure that the lap is clean after every usage and the gemstone should also be free from dust particles. This carelessness may lead to obtaining scratches on the gemstone. The environment where you are polishing the gemstones must also be free from dust particles to avoid deteriorating the quality of gemstones. Lastly, once the lap needs dressing, It must be done with precision and care such that a plane and flat surface of the polishing lap is obtained. SPECIFICATIONS: Arbor: ½” Diameter: 8” Depth (Polishing Region): ~8mm Overall Depth: ~22mm Ideal Running Speed: 1800 RPM Compound: Diamond SHIPPING INFORMATION: Time for shipping varies depending on the shipping region but usually, it takes a maximum of 5-7 business days to be delivered anywhere in the world, once it’s dispatched. The shipping of our Corundum polishing lap is insured. The lap is manufactured and shipped from India. For International customers, the fees on import duty or customs charges will not be incurred by us. Every country’s customs policies are different and must be considered by the customers on their own.

Diamond CBN grinding Flat Wheel

600 - 60,000 Per piece

GRINDEX INDIA is a polish tool company located in Ahmedabad, India. Beginnings of its business activities dates back to as far as the eighties of the last century. Nearly twenty-years-presence on the domestic market formed the company as respectable supplier of high quality Diamond & CBN grinding wheels. The production of high efficient conventional and modern grinding wheels allows the company to meet special demands of different branches of industry. In November 2002, the Quality Management System has been implemented confirmed with the ISO 9001:2000 standard. The quality policy of the company and constantly looking for possibilities of improvement contribute to the growth of domestic and abroad customers trust. The company's presence on European market is the best confirmation of this fact. GRINDEX INDIA is focused on delivering products exactly according to particular customer needs. Realise orders for special, untypical Diamond & CBN wheels with a short delivery time.Production range GRINDEX INDIA is the leading Polish manufacturer of grinding wheels. It offers following types of wheels. Resin bonded Diamond / CBN grinding wheels Vitrified bonded Diamond / CBN grinding wheels Metal bonded Diamond / CBN grinding wheels Hybrid bonded Diamond / CBN grinding wheels Rubber bonded Diamond / CBN grinding wheels Electroplated Diamond / CBN grinding wheels Industrial Diamond / CBN Products

Diamond Grinding Wheel

Get Price Quote

Sri ram abrasive tools resin bond diamond grinding wheels for manual machine operation super quality diamond very low cost & good quality.

diamond cup grinding wheels

1,450 Per Piece

For carving stone, especially hard granite. and making them into beautiful statues, garden art or memorials monuments tomb stones for loved ones. The dry cutter, needs no water. Grinds aways even the hardest granites into the designs exquisite. Available -n diameters - 4", 7" 8" Diamond - 32x48x9mm

Diamond Grinding Wheels

Get Price Quote

Diamond Grinding Wheels is used in many industries for grinding, such as Mechanical Seal Manufacturing Industry, High Alumina Ceramics Industry, Tungsten Carbide Tool Manufacturing Industry, Sintered Silicon Carbide Manufacturing Industry, Polycrystalline Diamond Insert Manufacturing Industry, Tungsten Carbide Insert Manufacturing Industry, etc. The best quality raw materials are used in production of Diamond Grinding Wheels, which we offer.

Turbo diamond cup grinding wheels

110 Per Piece

50 Piece(s) (MOQ)

diamond edging wheel

3,500 - 3,900 Per NOS

1 piece (MOQ)

With our rich industry experience, we have established ourselves to offer a wide array of Diamond Wheel. This diamond wheel is very important tool for cut/edge/polish spectacle lenses. We can supply diamond wheels of any size, any grit for any type operation especially for cutting, edging, bevel groove or polishing. These diamond wheels are manufactured by the experts using high grade quality components. Moreover, to ensure the compliance of the offered diamond wheels with the defined industry standards and quality parameters. Features: Robust Construction Long-lasting service Optimum performance Specifications: This is very important tool for cut/edge/polish spectacle lenses. We can supply diamond wheels of any size, any grit for any type operation especially for cutting, edging, bevel groove or polishi

Diamond And CBN Grinding Wheel With Hybrid bond

900 - 3,000 Per Piece

1 Piece(s) (MOQ)

Aluminium Straight Cup Grinding Wheel Diamond

3,000 - 10,000 Per Nos

a diamond grinding cup wheel is a metal-bonded diamond tool with diamond segments welded or cold-pressed on a steel (or other metal, such as aluminum) wheel body, which usually looks like a cup. diamond grinding cup wheels are usually mounted on concrete grinders to grind abrasive building materials like concrete, granite and marble. there are various styles and specifications of diamond grinding cup wheels to fit various application requirements. the ones with many big diamond segments can undertake heavy workloads, for example, grinding concrete and stone, while those with small or sparse diamond segments are normally used for fast removal of paints, wallpapers, glues, epoxy and other surface coatings. just like other metal-bonded diamond tools, the diamond segments on diamond grinding cup wheels can have different bonds, different diamond grits, different diamond quality and different diamond concentrations to fit different uses. for example, if the material to be ground is hard, the bond should be softer, and if the material is relatively soft, the bond should be harder. diamond grinding cup wheels are used in different-roughness grindings. for coarse grinding, the bond should be softer and the diamonds' quality should be higher, because in this case the diamonds become blunt more easily. the diamond grit should be bigger, normally from 35 grit to 50 grit. for this is coarse grinding and big grit can improve working efficiency. the diamond concentration can be lower. for fine grinding (sometimes called "polishing"), the bond should be harder and the diamonds' quality can be lower, as in this case the diamonds can last longer and a hard bond can also help the precision of the process. the diamond grit is normally between 80 grit and 120 grit, depending on the grinding requirements. the diamond concentration should be higher. after being ground, the material can be further polished with resin-bonded diamond polishing pads of different diamond grits.

Diamond Grinding Wheel

1,100 Per Piece

TACCHELLA TOOL AND CUTTER GRINDER

Get Price Quote

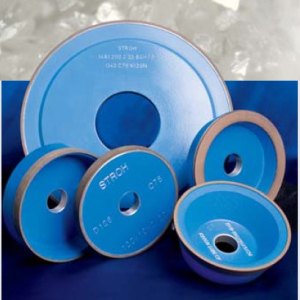

Diamond Grinding Wheels

5,000 - 250,000 Per piece

5 Piece (MOQ)

High precision and accurate diamond grinding wheels from Germany. Available in different sizes, natural or synthetic diamond, electroplated/reverse plated/CVD/MCD.

Stainless Steel Easilens Diamond Wheel,

3,200 Per piece

1 piece (MOQ)

Diamond Grinding Wheels

Get Price Quote

SUPER II RESIN BOND Diamond Grinding Wheels are stocked by us for various shapes & sizes as required by the end users. Tool Manufacturers & Re grinding Industry will find it easy to get required D.G.Wheel from Paul & Company.Choose a shape & size D.G. Wheel is available with Paul & Company. We can provide you the customized D.G.Wheel in the shortest time period. Paul & Company is also authorized distributor of EASTERN DIAMOND KOLKATTA FOR their electroplated D.G.Wheels. We keep in stock a lot of E.P. D. G. wheels in stock.

ELECTROMILL DIAMOND AND CBN GRINDING WHEELS

Get Price Quote

ElectroMill diamond and CBN electroplated grinding wheels replace expensive, complex indexable tungsten carbide or PCD milling cutters in high volume production finishing applications by consistently providing accurate flatness and part tolerances. With the right machine tool conditions and speed/feed parameters, throughput is significantly increased and tool costs, tool changeover and down-time cycles are dramatically reduced. ElectroMill can be successfully applied in marine, small-engine, automotive, off-road, agriculture, aerospace, defense and other industries – across a wide variety of components as well as ferrous, non-ferrous and exotic materials. Advantages:• Tool life of the ElectroMill has proven to be 50,000 pieces, consistently.• The mills are then sent back to Santechnik for strip and replate.• Tool quality, dimensional accuracy and life repeatability are the same as the original mill.

Diamond Grinding Wheel

Get Price Quote

Resin diamond grinding Wheels

Get Price Quote

This wheel is used to dry grind and polish ceramic/ crystal bricks of all sizes. It is high quality, stable, durable and precise and will not damage the bricks easily.

Diamond Grinding Wheel

250 Per Pair

Diamond dc wheel are used in foundries for grinding different materials.